33 End Float Checking - Forward/Reverse Unit

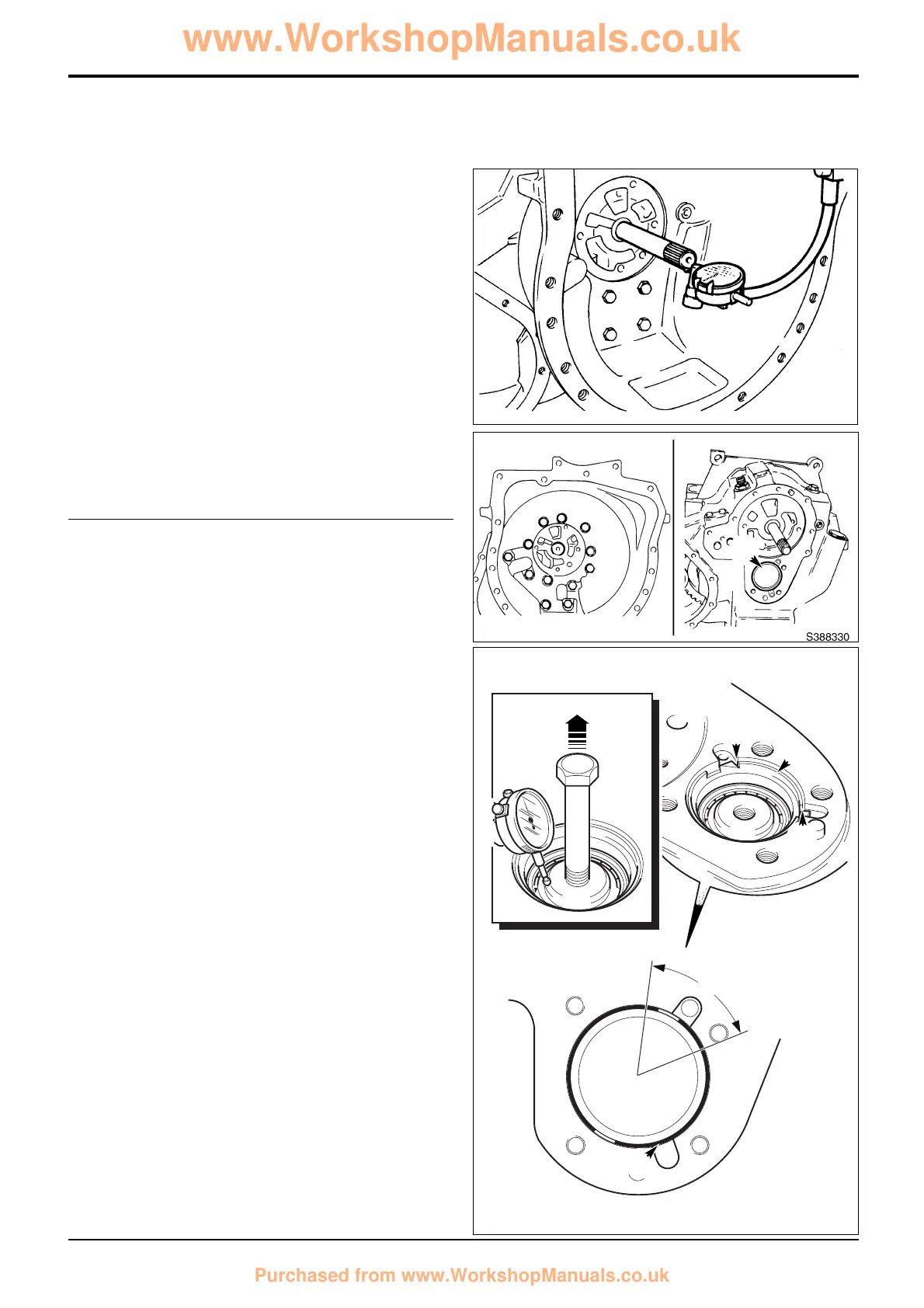

Measure end float of forward/reverse unit shaft which

should be 0.01 to 0.16 mm (0.0004 to 0.006 in).

Note: Rotate shaft whilst measuring to seat bearings fully.

Position pointer of dial test indicator (DTI) on the chamfer of

the shaft, not the end face. This will ensure a constant

reading is given.

The forward/reverse shaft and its associated

components are manufactured using a ‘Setright’

system. Provided components are assembled correctly

the end float will be within the limits given above.

If there is no float, or too much end float, separate the

casings and check that the bearings inner and outer

cups are fitted correctly. If the forward/reverse shaft

and clutch assemblies have been dismantled check that

the assembly has been carried out correctly.

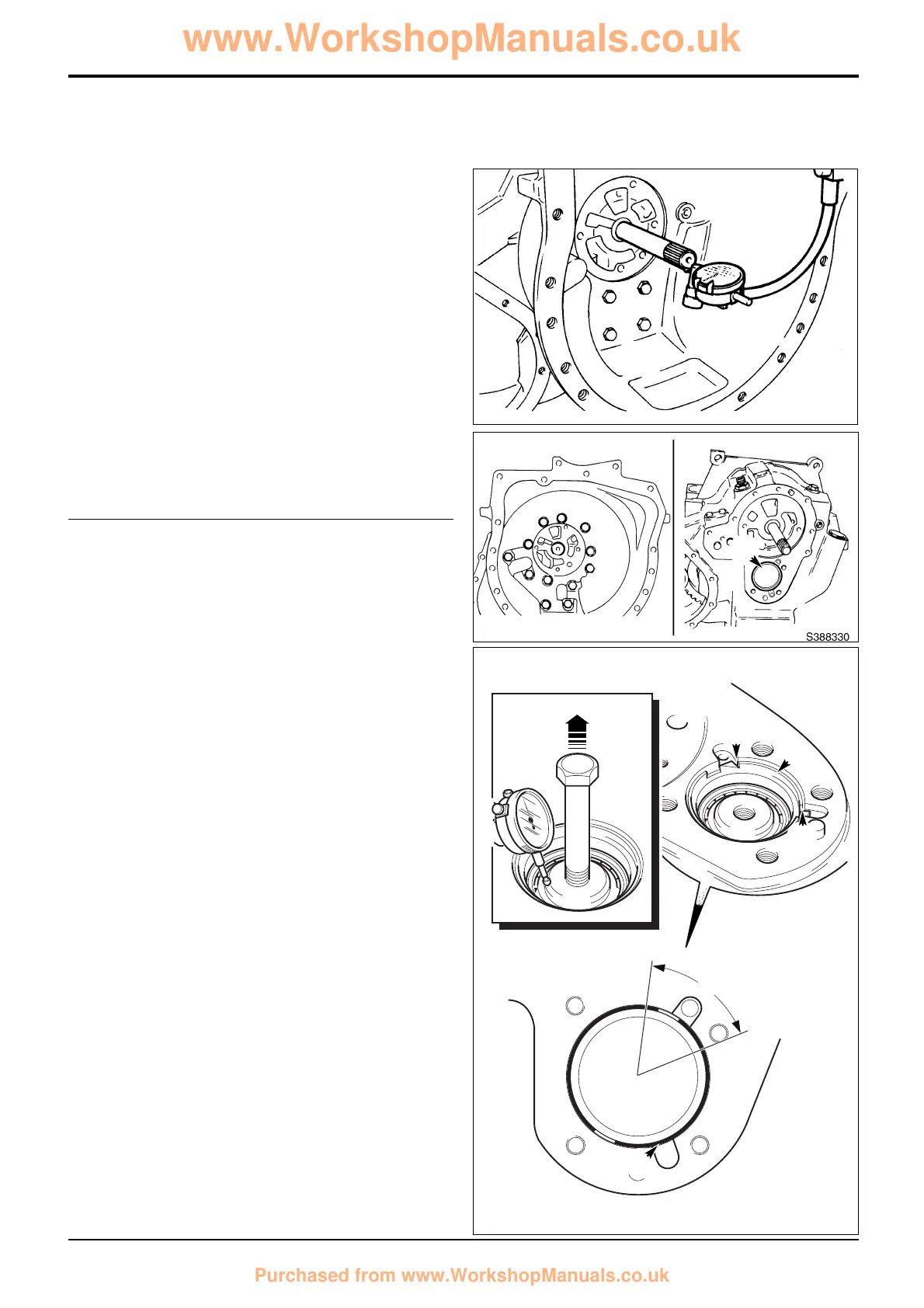

34 End Float Setting - Mainshaft

If the mainshaft, output shaft and/or associated

bearings have been renewed, the shaft end float must

be reset.

a Remove the torque converter housing and position

the gearbox to gain access to setting ring A.

b Using service tool 892/01079 tighten the setting ring

to 25 Nm (18.4 lbf ft) whilst at the same time

rotating the shaft via the output yoke (a gear must

be engaged). Do not over tighten the ring.

Overtightening will damage the bearings.

c Undo the ring a small amount to obtain a shaft end

float of 0.03 to 0.08 mm (0.001 to 0.003 in). To

measure the endfloat screw in a bolt (or service tool

892/01078) at the threaded hole in the end of the

shaft. Set up a DTI with the probe on the chamfer of

the shaft. Zero the DTI. Rotate the shaft and at the

same time pull up on the bolt, noting the reading on

the DTI. Screw the ring in or out until the end float is

correct.

d When the correct setting has been obtained, stake

the setting ring to the casing as shown at Y (see the

note below). Note that once staked the setting ring

can not be used again. If the ring is disturbed it must

be discarded and a new one used to re-set the end

float.

Note: If the slots in the setting ring fall close (within zone Z)

to the staking position Y, stake at position X instead. In this

event the ring must also be folded on one side at position Y,

fold on the side furthest away from the slot in the ring. This is

important as the ring will otherwise restrict the flow of

lubrication oil.

112-9

Section F Transmission

9803/3280

Section F

112-9

Issue 2*

Synchro Shuttle Transmission

Assembly (cont'd)

S221201

A

Loading...

Loading...