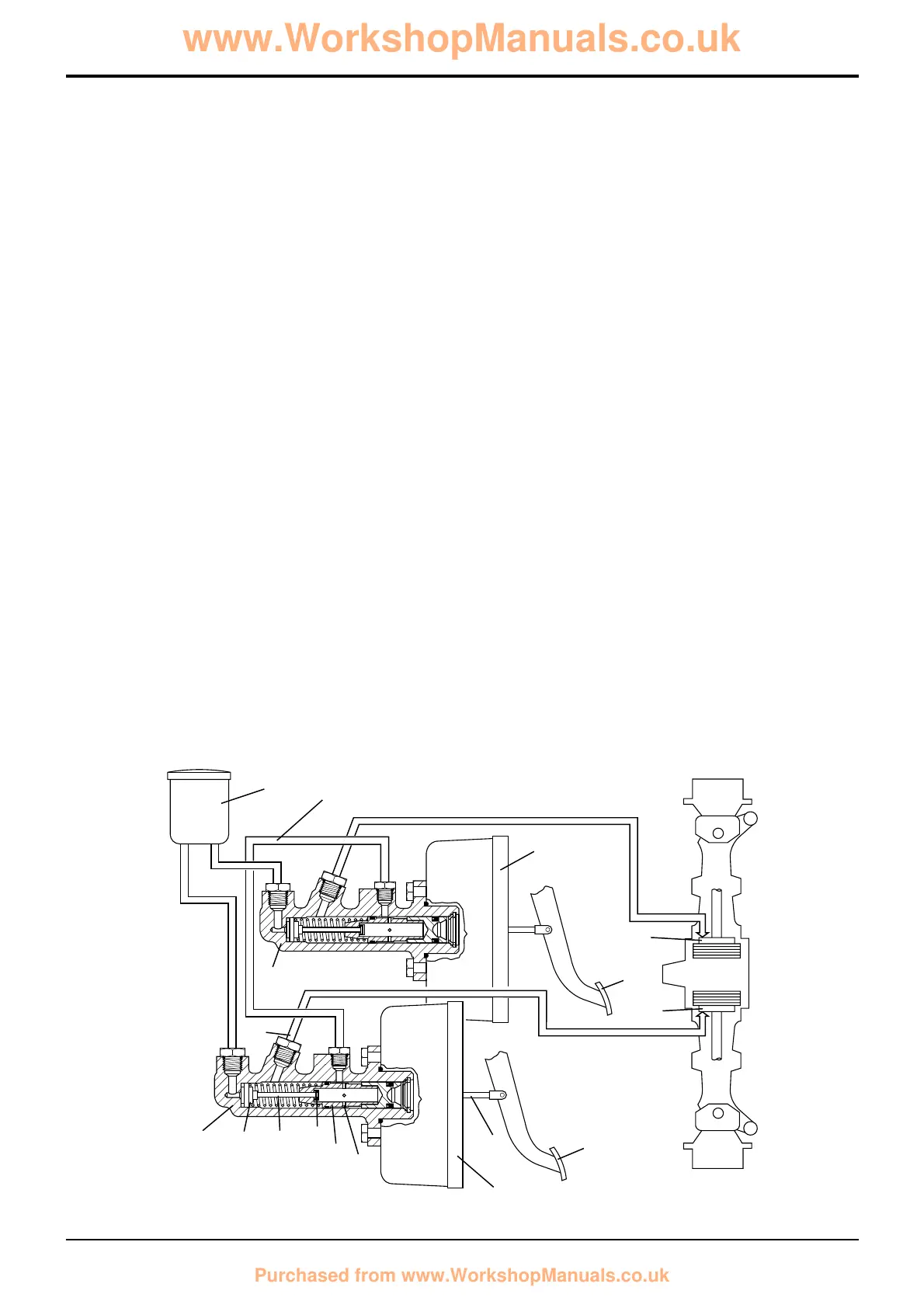

Compensating Master Cylinder

Description

Compensating master cylinders overcome the problem of

unequal wear between the right and left brake. The units

incorporate both master cylinder and compensating valve.

Each brake has its own master cylinder A, A1, brake pedals

B, B1, servo units N, N1 and associated pipework. Both

master cylinders have one common reservoir C.

Note: Dual pedal braking is applicable only to 2WS

machines. 4WS machines have a single brake pedal.

Pedals Locked - Normal Operation

When the brake pedals are pushed down (the brake pedals

are mechanically locked together), rod D pushes the plunger

E down the bore of the master cylinder. Pressurised oil

acting on centre valve seal F via valve stem G causes the

seal to close off the reservoir supply port. As the plunger

continues to move down the bore, pressurised oil flows to

the brake pack H via service port J and the associated

pipework.

Master cylinder A1 operates in the same way to feed brake

pack H1.

With valve stem G at maximum travel, further movement of

plunger E causes valve K to lift off its seat. Both master

cylinders are interconnected via bridge pipe M, therefore

hydraulic pressure in both cylinders will be equal.

If the brake packs H and H1 have worn equally, then the

amount of oil displacement between cylinders will be

minimal and the brakes will be applied evenly.

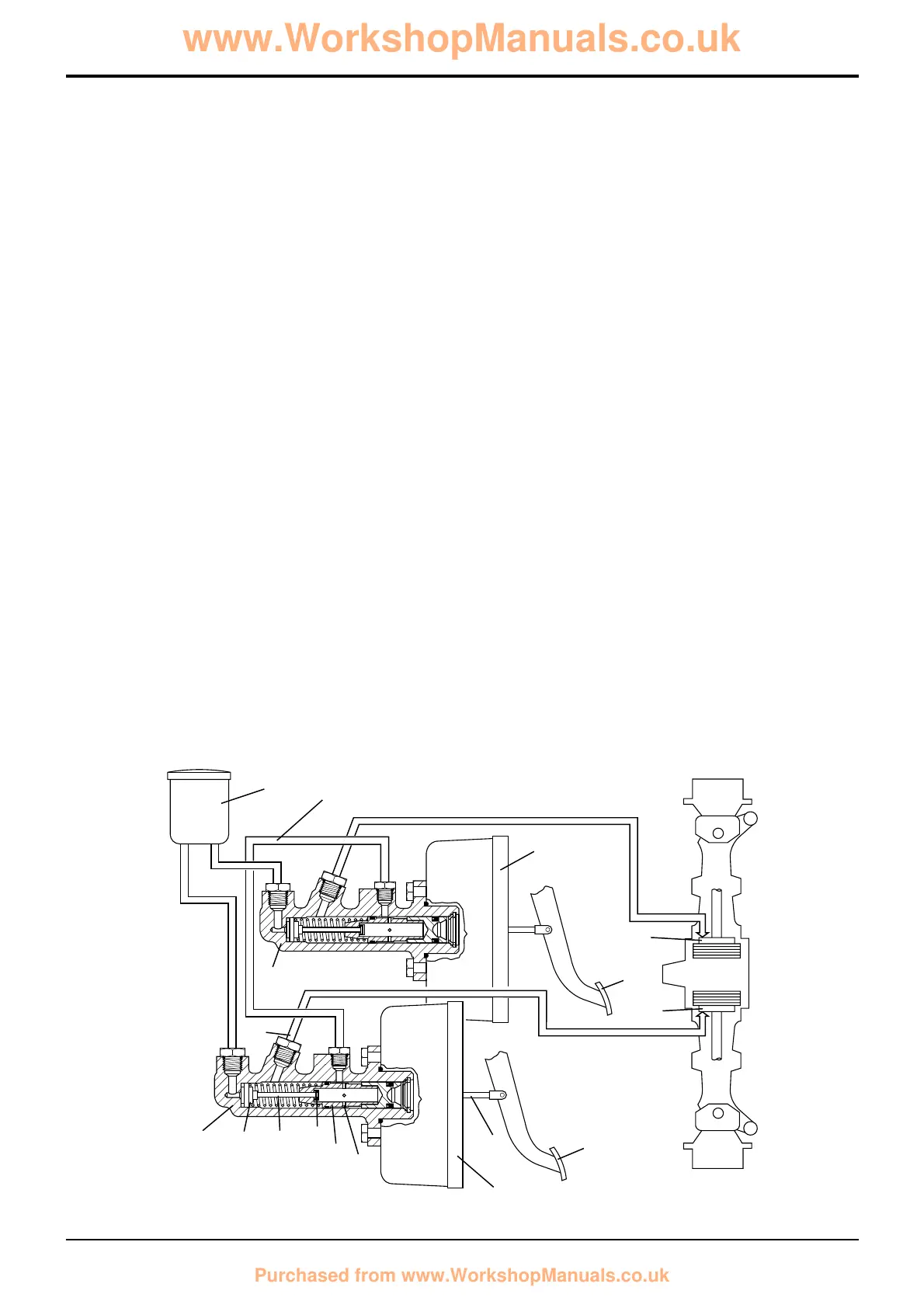

Pedals Locked - Compensating Operation

When the brake pedals are pushed down (the brake pedals

are mechanically locked together), actuation of the brake

packs H and H1 is as described in Pedals Locked - Normal

Operation. If however, the brakes have not worn equally,

then the amount of fluid displaced from each master

cylinder will vary and some form of compensation is

required.

Pedal application moves plungers E down the bores of

master cylinders A and A1. Linings of brake H are brought

into contact before the linings of brake H1 because they

have not worn as severely.

If further displacement took place at the linings, brake H

would be applied before brake H1. Therefore master

cylinder A begins to compensate for master cylinder A1.

Fluid is displaced from A to A1 via bridge pipe M until the

pressures are equalised. In this condition both

compensating valves are open and both brakes are applied

evenly.

Pedals Unlocked - Normal Operation

When a single brake pedal is pushed down, rod D pushes

the plunger E down the bore of the master cylinder.

Pressurised oil acting on centre valve seal F via valve stem

G causes the seal to close off the reservoir supply port. As

the plunger continues to move down the bore, pressurised

oil flows to the brake pack H via service port J and

associated pipework, thus braking one wheel only.

With valve stem G at maximum travel, further movement of

plunger E causes valve K to lift off its seat. Fluid is

displaced through drillings P from the active cylinder A via

bridge pipe M to passive cylinder A1. Valve K1 in the

passive cylinder is held on its seat by the displaced

pressurised fluid.

3 - 1

Section G Brakes

9803/3280

Section G

3 - 1

Issue 1

Basic System Operation

Loading...

Loading...