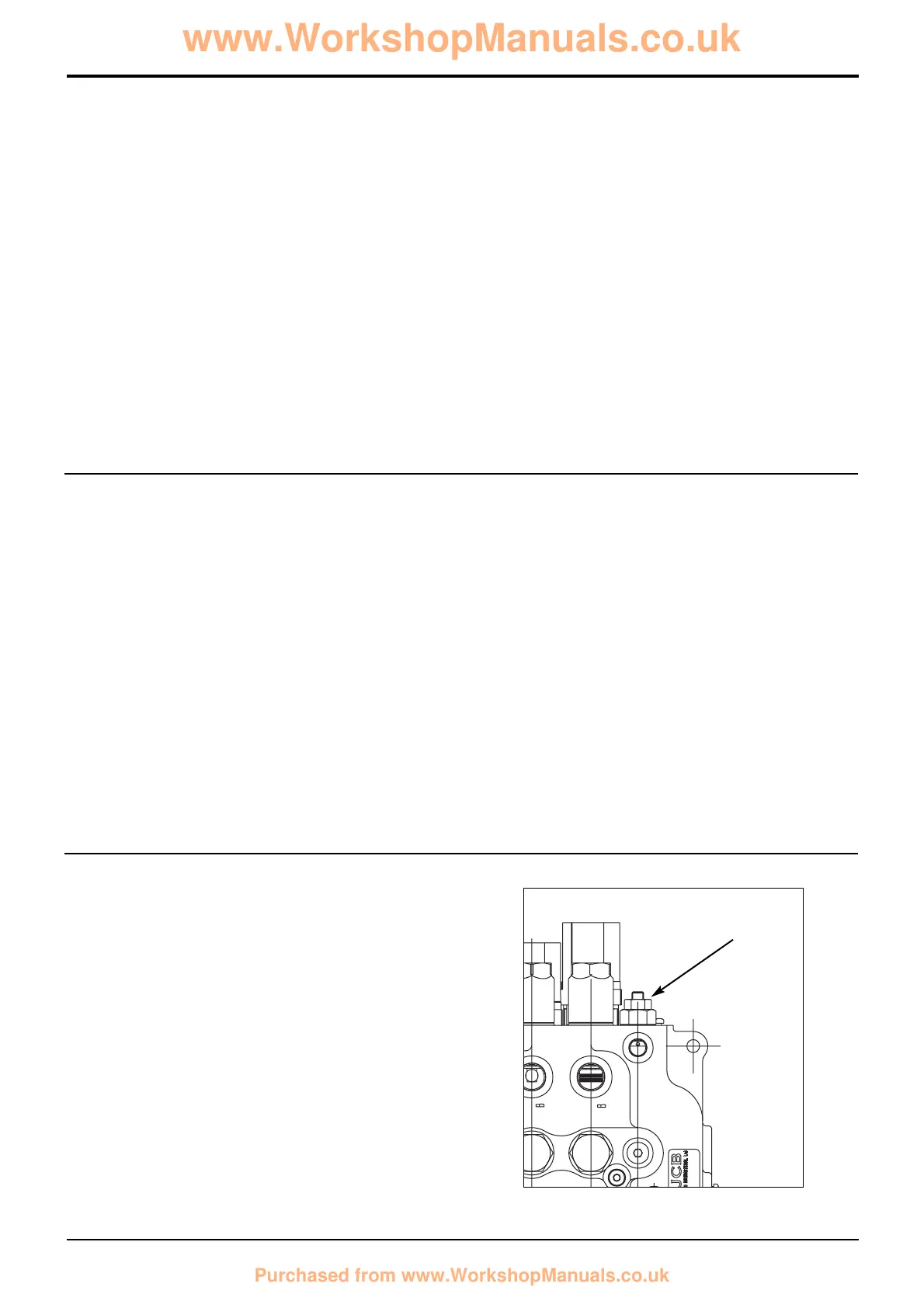

Excavator Valve

Precision Control (Servo) (continued)

(Machines up to serial no. 931159)

Load Sense (Isolator Compensator) Valve

Operation

No service is selected (all spools in neutral)

With the spools in the neutral position oil from the pump P

flows to each spool and is dead ended. This generates

sufficient pressure (about 20bar) to overcome the spring E1

and oil flows across the bypass compensator spool

assembly E to tank. Note that oil from the pump also flows

into the ‘auxiliary pump gallery’ 1. Oil from the ‘bridge

galleries’ 3 is vented to tank via a groove in the main spool S.

8 - 16

Section E

Hydraulics

9803/3280

Section E

8 - 16

Issue 2*

Circuit Descriptions

Spool at point of operating a service

Pressure from the load on ram R enters the bridge gallery 3

via the service port 4. Compensator check valve H is held

down on its seat preventing the load moving. At the same

time the isolator spool U lifts and allows oil from the auxiliary

pump gallery 1 to flow into the load sense gallery 2. Oil

pressure builds in gallery 1 and the bypass compensator

spool E begins to close under the action of the oil and spring

(E1) pressure. This causes the pump pressure to rise to a

new value as follows:

Pump pressure = Pressure in load sense gallery 2 + pressure

from spring E1.

When the pressure in load sense gallery 2 reaches the load

pressure, isolator spool U moves down and closes off the

auxiliary pump gallery 1 from load sense gallery 2. If the load

pressure subsequently rises or falls, the isolator spool moves

due to pressure imbalance and maintains the pressure in the

load sense gallery 2 at the same pressure as the load

pressure. The pressure in the load sense gallery 2 always

Spool fully operating a service

As the spool S is moved further oil from the pump is diverted

into the central gallery 5. If the pump pressure has risen

sufficiently (to a pressure equal to the load + spring pressure

E1) then check valve H moves up off its seat and allows oil

to flow into bridge gallery 3, and out to the ram R via service

port 4. Exhaust oil from the other side of ram R is diverted to

tank.

bleeds to tank, again causing pressure imbalance and the

isolator spool to move, allowing the pressure in the gallery to

be ‘topped up’. This ensures that ‘pressure balance’ is

always maintained.

It must be noted that the load sense gallery 2 is connected to

all load sense valves (one for each service). The pressure in

the gallery 2 will always be equal to the highest load from

any of the backhoe services. The maximum load sense

pressure is regulated by the load sense drain regulator/relief

valve F (see below).

Any load on the service ram R is held by the main spool S.

Oil is also vented to tank from the load sense gallery 2 via

the load sense drain regulator/relief valve F (see below).

F

*

Loading...

Loading...