1 - 5

Rivet Nut Tool Procedure

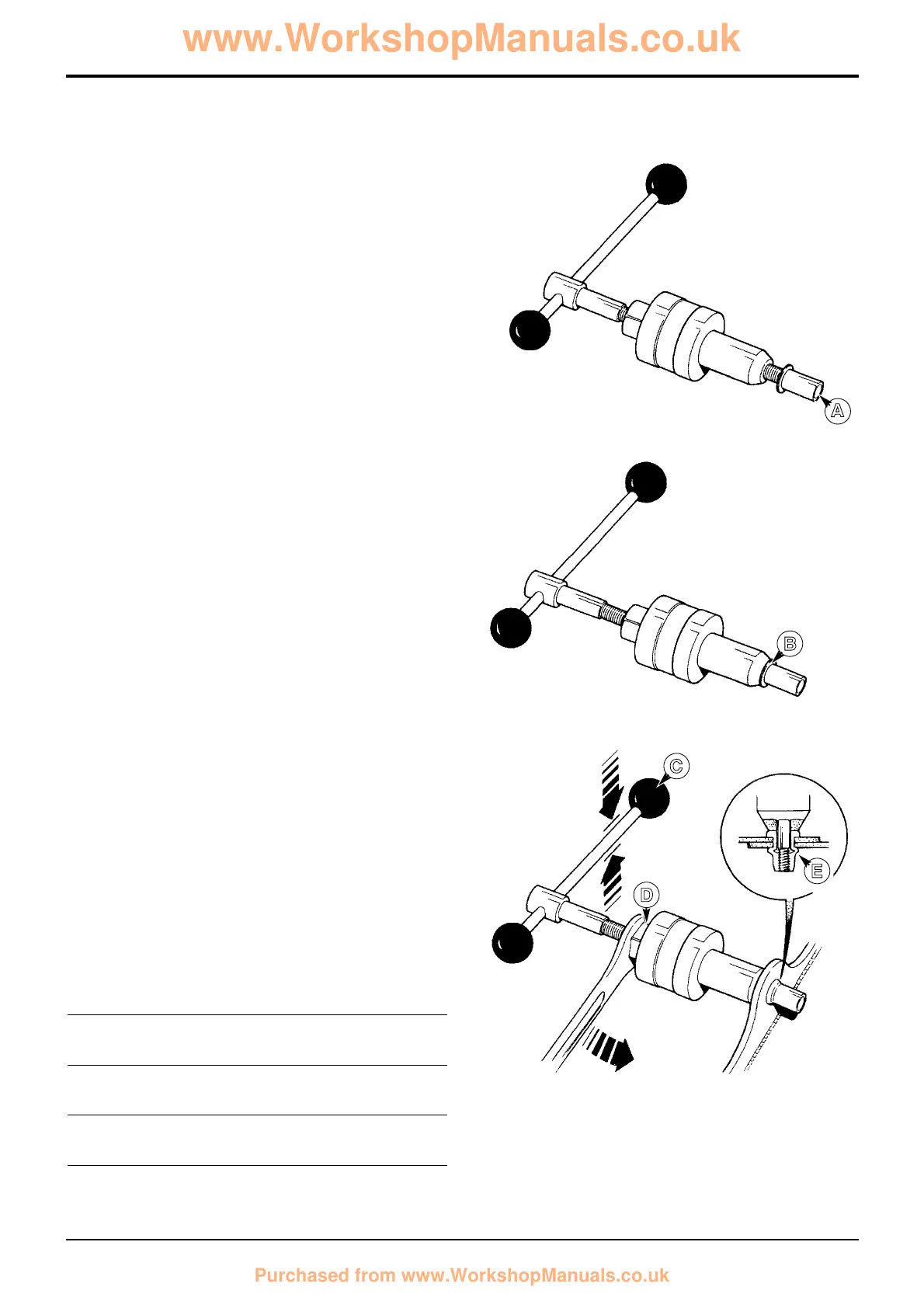

A 'Rivet Nut' is a one piece fastener installed 'blind' from

one side of the machine body/framework. The rivet nut is

compressed so that a section of its shank forms an 'upset'

against the machine body/framework, leaving a durable

thread (see illustrations).

Rivet nuts are fitted to various parts of the machine body

and framework. They are used in a number of applications,

for instance, hose clamp and hydraulic valve retention etc.

Various sized rivet nuts are available, see the table below to

determine the size of rivet nut to be used for particular

applications.

If for any reason a new rivet nut requires fitting, then the

correct installation procedure must be followed:

1 Drill a hole in the machine body/framework where the

rivet nut is to be fitted. De-burr hole edges.

2 Screw the rivet nut onto the mandrel of the installation

tool. The bottom of the mandrel should be in line with

the bottom of the rivet nut, shown at A.

3 Wind the body of the installation tool down the

threaded mandrel until it touches the head of the rivet

nut, shown at B.

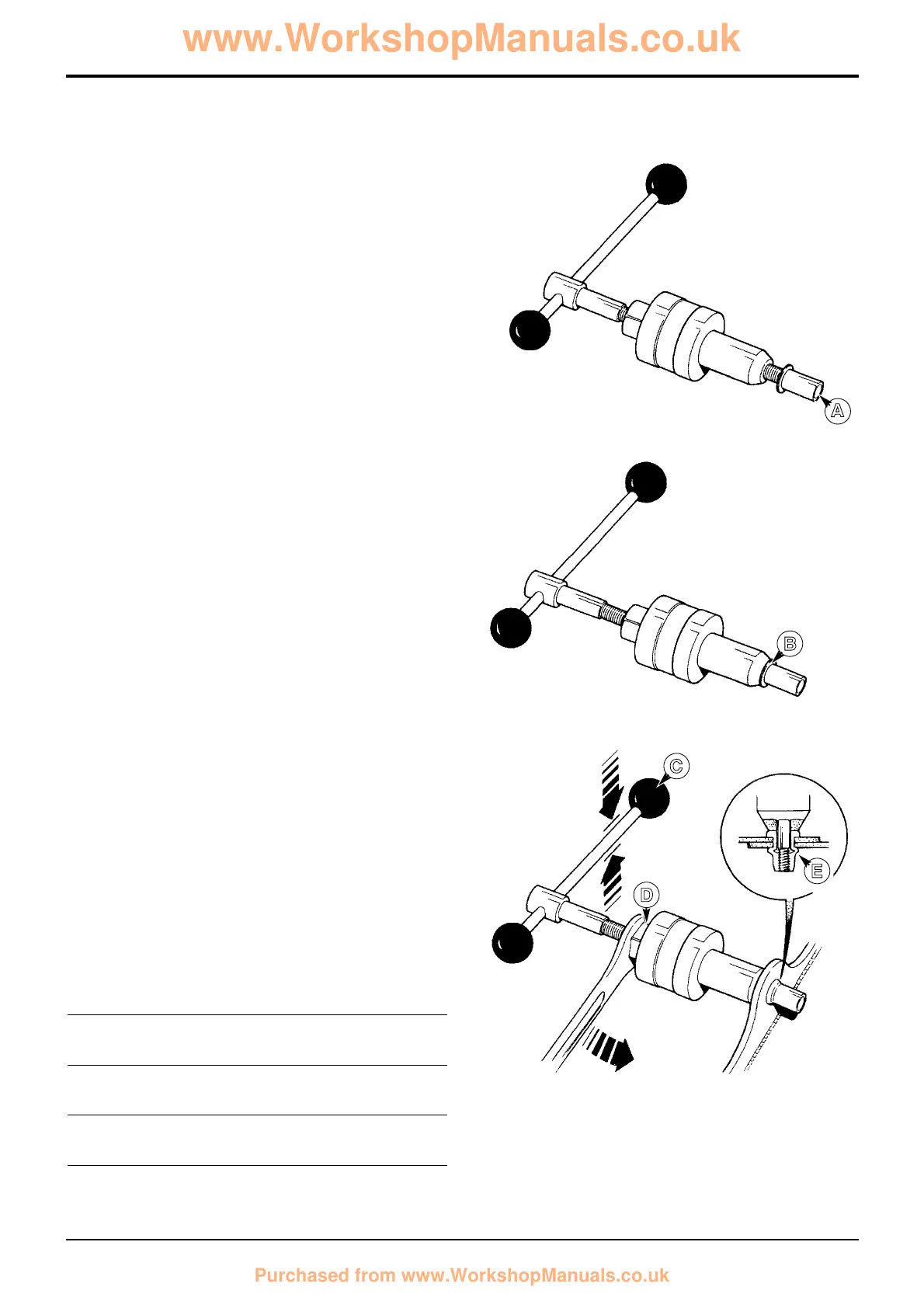

4 Insert the rivet nut (assembled to the tool) into the hole

drilled in step 1.

5 Hold handle C and at the same time draw the mandrel

into the installation tool by turning nut D. The rivet nut

will contract in length and form an 'upset' (smooth

bulge) seating itself against the body/framework (see

inset E).

Note: The thread of the rivet nut must not be stripped, take

care when 'upsetting' the rivet nut.

6 Remove the installation tool.

Specifications (all dimensions in mm)

Rivet Nut Rivet Nut Material Rivet Drill

Thread Outside Thickness Length Hole

Diameter Diameter (Total) Dia.

M5 7 0.25 - 3.00 14.00 7.10

3.00 - 5.50 17.00

M6 9 0.50 - 3.00 16.00 9.10

3.00 - 5.50 19.00

M8 11 0.50 - 3.00 18.00 11.10

3.00 - 5.50 21.00

M10 13 1.00 - 3.50 23.00 13.10

3.50 - 6.00 26.00

Note: In an emergency, and if no installation tool is

available, it is possible to fit a rivet nut by using a nut and

bolt the same thread diameter as the rivet nut being

installed. However, this is not the recommended method.

Section B Body & Framework

9803/3280

Section B

1 - 5

Issue 1

Service Tools

S150970

A

B

C

D

E

Loading...

Loading...