4.4.5 Assembly of the wires to PUSH IN terminals

NOTICE

Malfunctions caused by loose cable connections!

► Observe metal sleeve length and stripping length

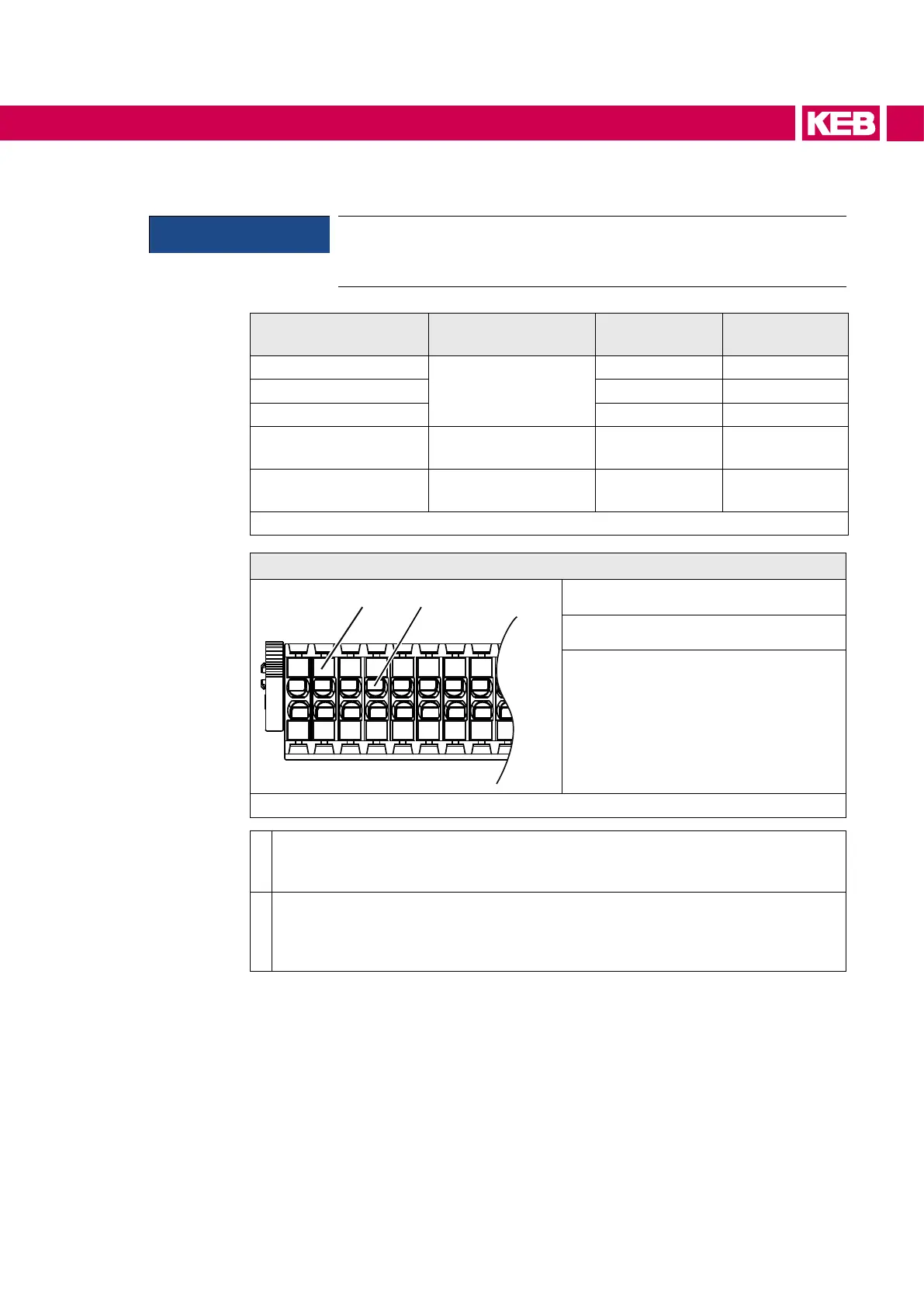

Cross-section Wire-end ferrule

Metal sleeve

length

Stripping

length

0.50mm

2

with plastic collars

(DIN 46228-4)

10mm 12 mm

0.75mm

2

12 mm 14 mm

1.00mm

2

12 mm 15 mm

1.50mm

2

without plastic collars

(DIN 46228-1)

10mm 10mm

0.2…1.5mm

2

single-wireorne-wire

without wire-end

ferrule

– 10…15mm

Table 18: Wire-end ferrules and stripping length

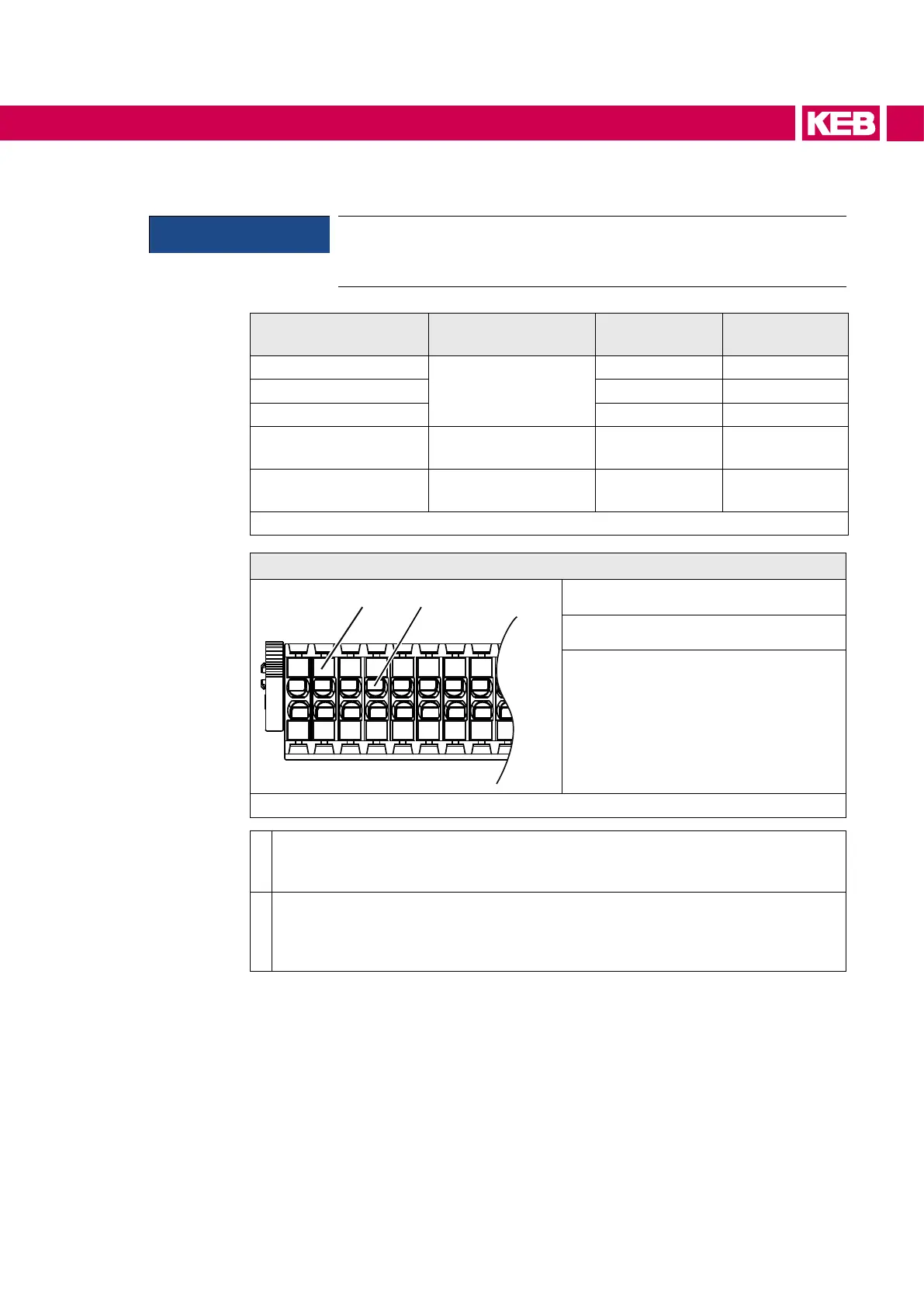

Front view

a) Pusher

b) Wire hole

Figure 35: Assembly of the control cable

•

Press pusher by hand. Insert connecting wires into the respective hole, that no

singlewirescanbeseenfromtheoutsideorbendoutward.Arstresistancemust

be overcome when inserting. Release the pusher.

•

Checkthattheconnectingwireisxedandcannotbepulled-out.Itisimportantto

ensure that the connecting wire and not the insulation is clamped. The connecting

wire can also be inserted without pressing the pusher in case of cross-sections

upto1.00mm².

61

CONNECTION OF THE CONTROL

Loading...

Loading...