10.1

Section 10

Reassembly

10

Section 10

Reassembly

The following sequence is suggested for complete

engine reassembly. This procedure assumes that all

components are new or have been reconditioned, and

all component subassembly work has been completed.

This procedure may be varied to accommodate

options or special equipment.

NOTE: Make sure the engine is assembled using

all specified torque values, tightening

sequences, and clearances. Failure to observe

specifications could cause severe engine wear

or damage.

NOTE: Always use new gaskets.

NOTE: Make sure all components have been

properly cleaned BEFORE reassembly.

NOTE: Apply a small amount of oil to the threads

of critical fasteners before assembly, unless a

Sealant or Loctite® is specified or preapplied.

Typical Reassembly Sequence

The following sequence is suggested for complete

engine reassembly. This procedure assumes that all

components are new or have been reconditioned, and

all component subassembly work has been completed.

The sequence may vary to accommodate options or

special equipment. Detailed procedures follow:

1. Install PTO side oil seal.

2. Install governor cross sha.

3. Install oil pump and intake cam sha assembly.

4. Install cranksha and balance weight.

5. Install piston rings.

6. Install piston to connecting rod.

7. Install piston and rod to cranksha.

8. Install cam levers.

9. Install exhaust cam sha, cam gear and ACR.

10. Install intake cam gear.

11. Install oil seal into closure plate (flywheel side).

12. Install closure plate gasket, closure plate and

wiring harness.

13. Assemble cylinder head.

14. Install cylinder head.

15. Install rocker arms and push rods.

16. Install valve cover.

17. Install stator and wiring harness.

18. Install flywheel and fan.

19. Install electric starter.

20. Install ignition module.

21. Install spark plug.

22. Install heat deflector, carburetor, linkage, and air

cleaner base.

23. Install and adjust governor lever, mounting speed

control bracket.

24. Install fuel pump (some models).

25. Install rectifier-regulator.

26. Install blower housing and flywheel screen.

27. Install Oil Sentry™ switch or pipe plug.

28. Install air cleaner element, precleaner and air

cleaner cover.

29. Install muffler.

Install PTO Side Oil Seal

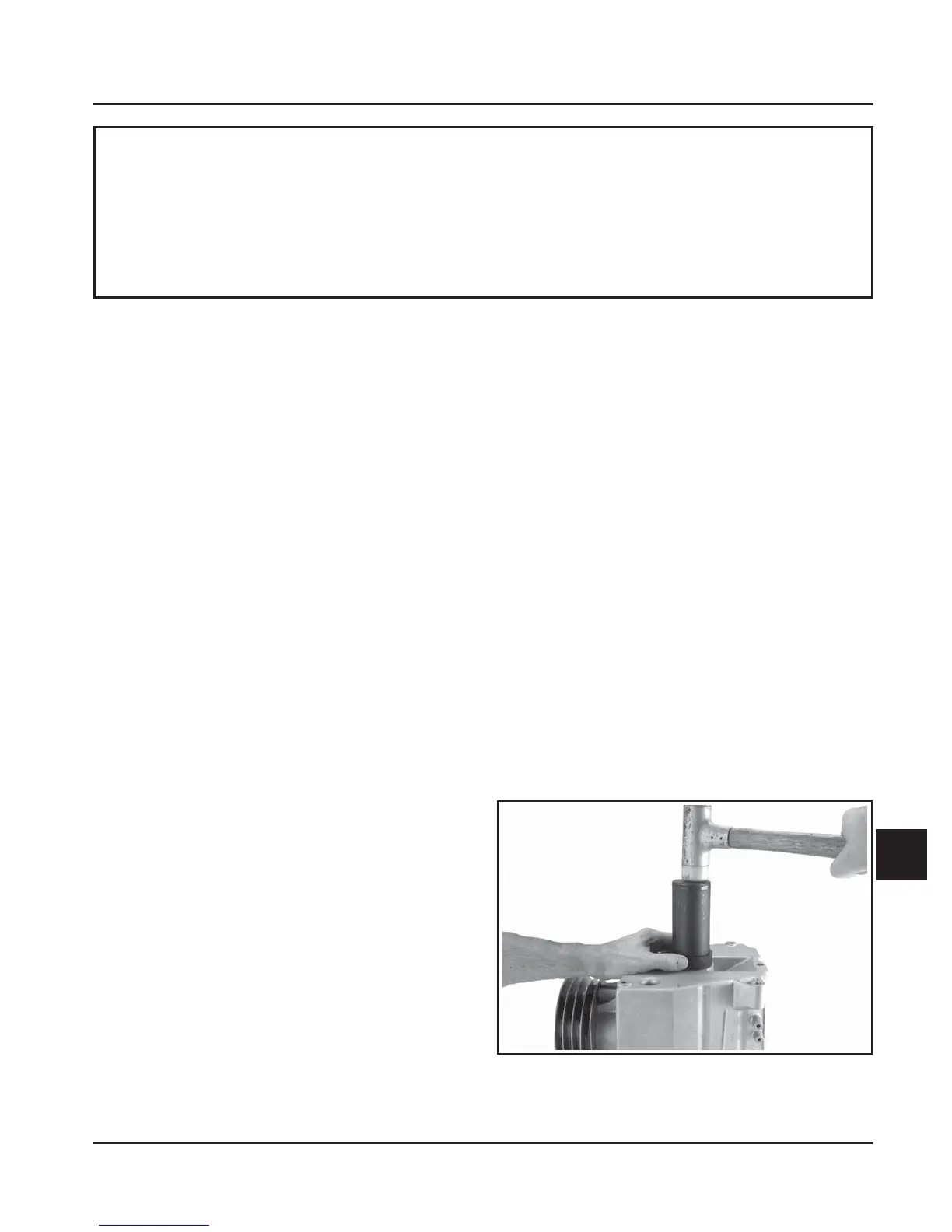

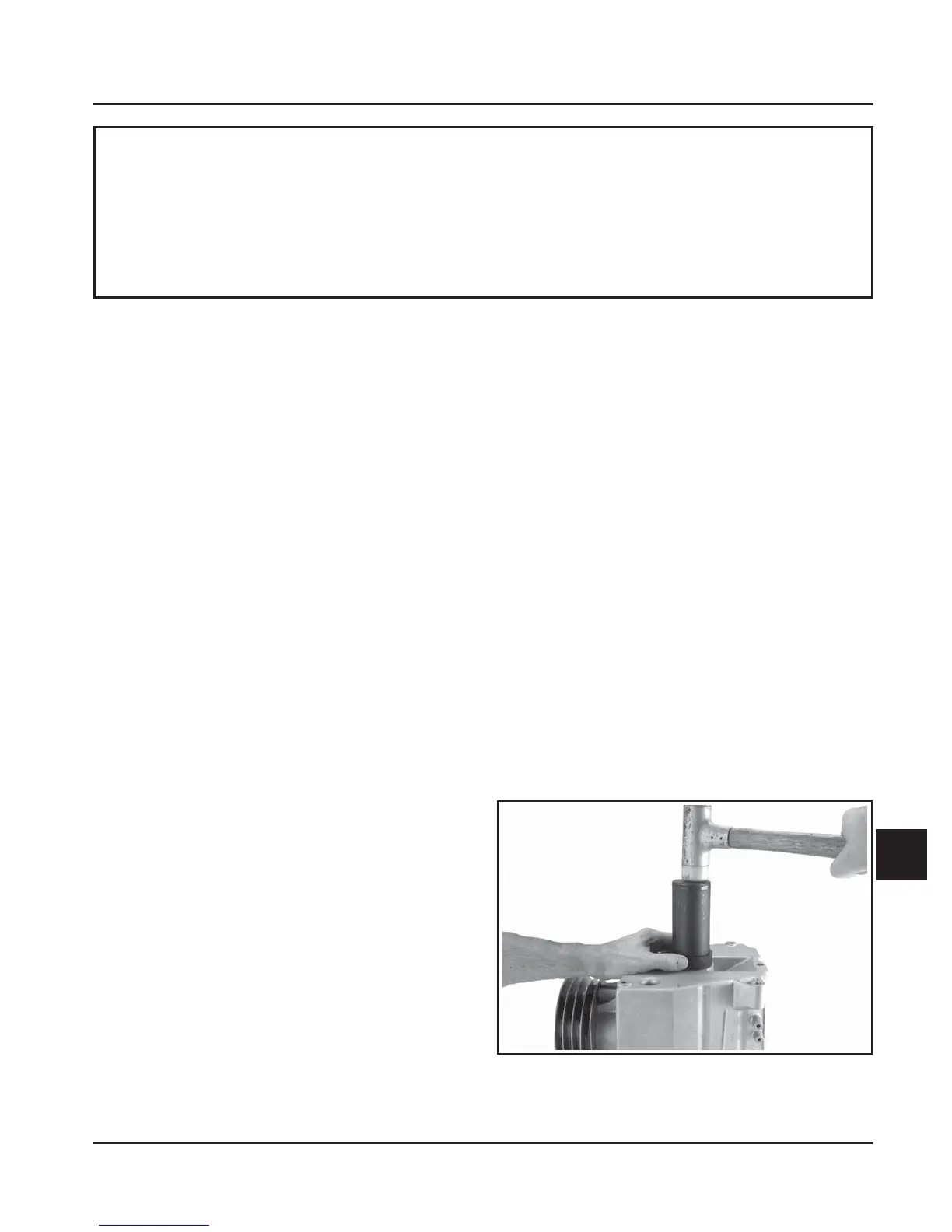

1. Use a seal driver and install to a depth of 5.5 mm

(0.216 in.) into the crankcase. See Figures 10-1

and 10-2.

Figure 10-1. Installing PTO Side Oil Seal.

Loading...

Loading...