6.3

Section 6

Lubrication System

6

NOTE: To prevent extensive engine wear or

damage, always maintain the proper oil

level in the crankcase. Never operate

the engine with the oil level below the

‘‘L’’ mark or over the ‘‘F’’ mark on the

dipstick.

Full-Pressure Lubrication System

Operation

This engine uses a full-pressure lubrication system

to deliver oil for internal lubrication. A cam driven,

high efficiency Gerotor

™

oil pump located in the

crankcase maintains proper oil flow and oil pressure

even at low speeds and high operating temperatures.

Oil is supplied from the pump via two circuits to the

cranksha main bearings, cranksha, connecting

rod bearing surfaces, cam gears, and axis shas. An

integral pressure relief valve within the oil pump

limits the maximum pressure of the system.

For a cold engine at start up, the oil pressure can

go up to 20-25 psi. For a warm (normal operating

temperature) engine at idle speed, the oil pressure can

go down to 5 psi.

Service

The oil pump rotors typically require no servicing, if

normal maintenance is performed as outlined in

Section 1.

The closure plate must be removed for access to the

oil pump and the rotors. Refer to the Disassembly

and Reassembly, Sections (8 and 10), for removal and

reinstallation procedures.

Figure 6-7. Oil Pump on Intake Cam Shaft

(Gerotors Removed from Pump Housing).

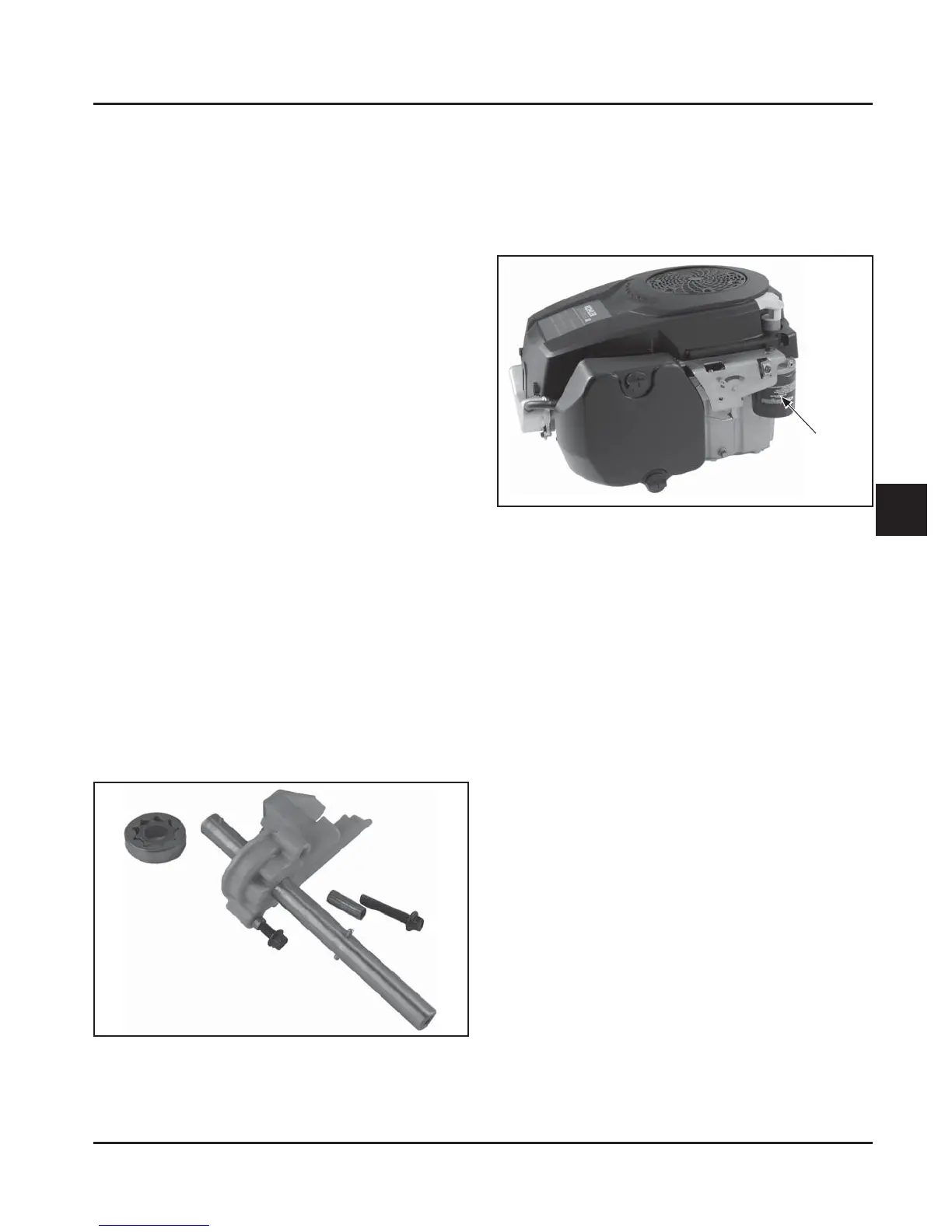

Oil Filter

These engines are equipped with a full-flow oil filter.

See Figure 6-8.

The oil filter helps remove sludge and other

combustion by-products from the oil. It also extends

the oil change interval and cools the oil.

Oil Filter

Figure 6-8. Oil Filter Location.

Oil Sentry

™

Some engines are equipped with an optional Oil

Sentry™ switch. This switch is designed to prevent

the engine from starting in a low oil or no oil

condition. The Oil Sentry™ may not shut down

a running engine before damage occurs. In some

applications this switch may activate a warning signal.

Read your equipment manuals for more information.

Operation

The pressure switch is designed to break contact

as the oil pressure increases and make contact as

the oil pressure decreases. At oil pressure above

approximately 2 to 5 psi, the switch contacts open.

At oil pressures below approximately 2 to 5 psi, the

switch contacts close.

On vehicular applications (lawn tractors, mowers,

etc.), the pressure switch can be used to activate a

low oil warning light. On stationary or unaended

applications, the pressure switch can be used to

ground the ignition module to stop the engine.

NOTE: Oil Sentry

™

is not a substitute for checking

the oil level BEFORE EACH USE. Make sure

the oil level is maintained up to the ‘‘F’’ mark

on the dipstick. See Figure 6-5.

Loading...

Loading...