10.7

Section 10

Reassembly

10

Install Piston and Connecting Rod

NOTE: Proper orientation of the piston/connecting

rod inside the engine is extremely important.

Improper orientation can cause extensive

wear or damage.

1. Stagger the piston rings in the grooves until the

end gaps are 120° apart. Lubricate the cylinder

bore, cranksha journal, connecting rod journal,

piston, and rings with engine oil.

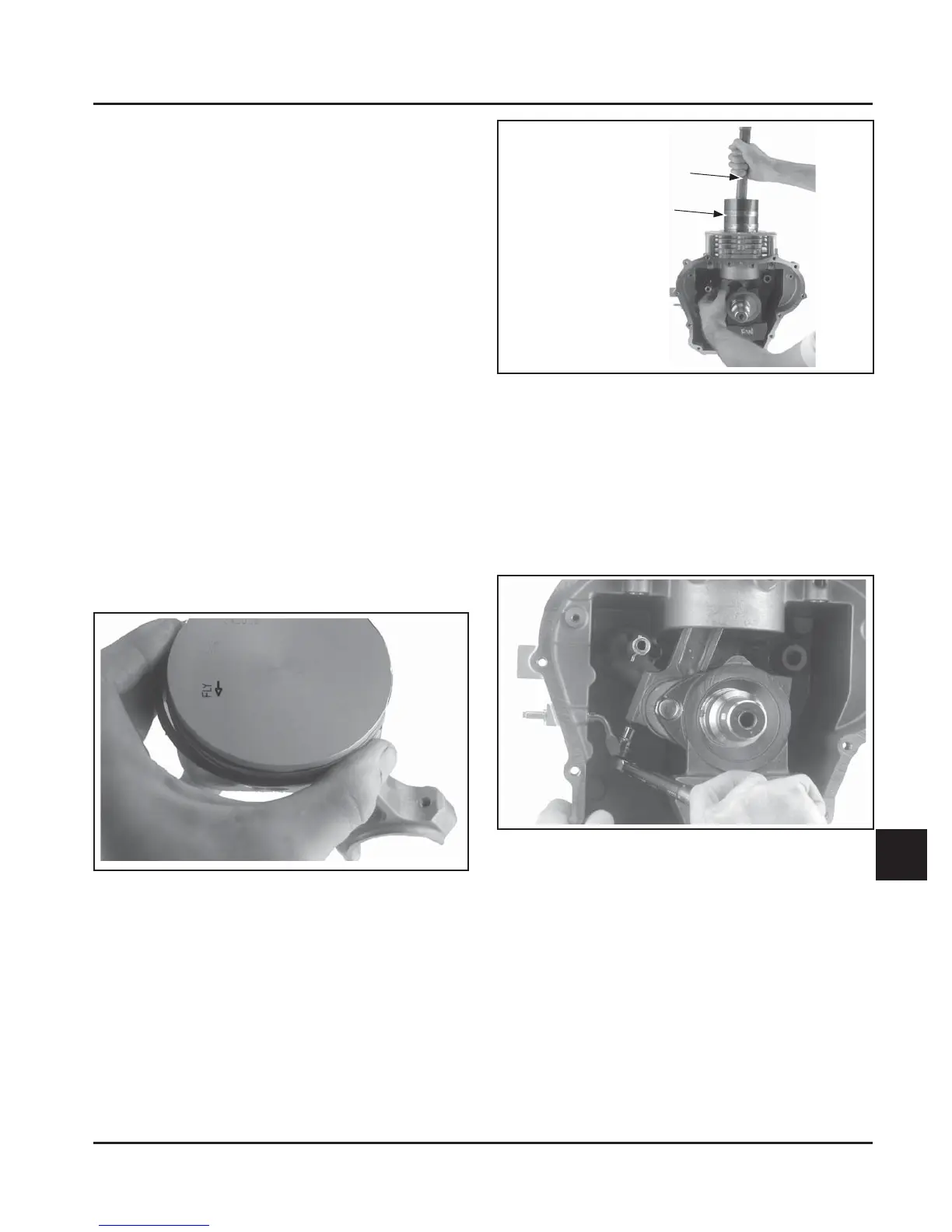

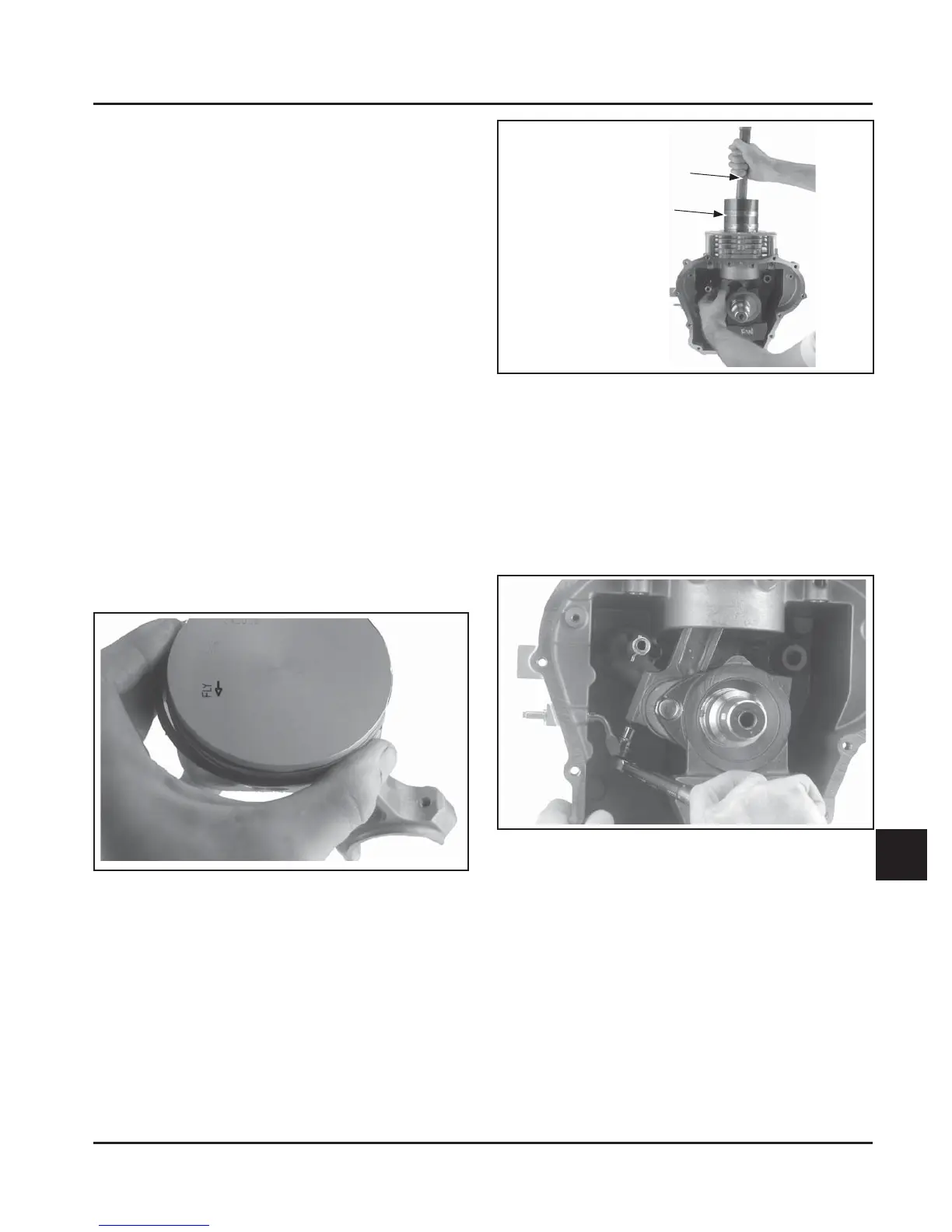

2. Compress the piston rings using a piston ring

compressor. Orient the FLY mark on the piston

toward the flywheel side of the crankcase. See

Figure 10-22. Place the ring compressor on the

top surface of the crankcase and make certain it

is seated down around the entire circumference.

Use a so, rubber grip hammer handle and tap

the piston/connecting rod into the bore. See

Figure 10-23. The first tap should be rather firm,

so the oil ring moves from the compressor into

the bore in one smooth, quick motion. Otherwise

the oil ring rails may spring out and jam between

the ring compressor and the top of the bore.

Figure 10-22. Direction Arrow on Piston.

Figure 10-23. Installing Piston and Connecting

Rod.

3. Guide the connecting rod down and rotate the

cranksha to mate the journals. Install the rod

cap.

4. Install the hex flange screws and torque in 2

increments, first to 5.5 N·m (50 in. lb.), finally to

11.5 N·m (100 in. lb.). See Figure 10-24.

Figure 10-24. Torquing Connecting Rod Screws.

Ring Compressor

Soft End

of Handle

Loading...

Loading...