5.10

Section 5

Fuel System and Governor

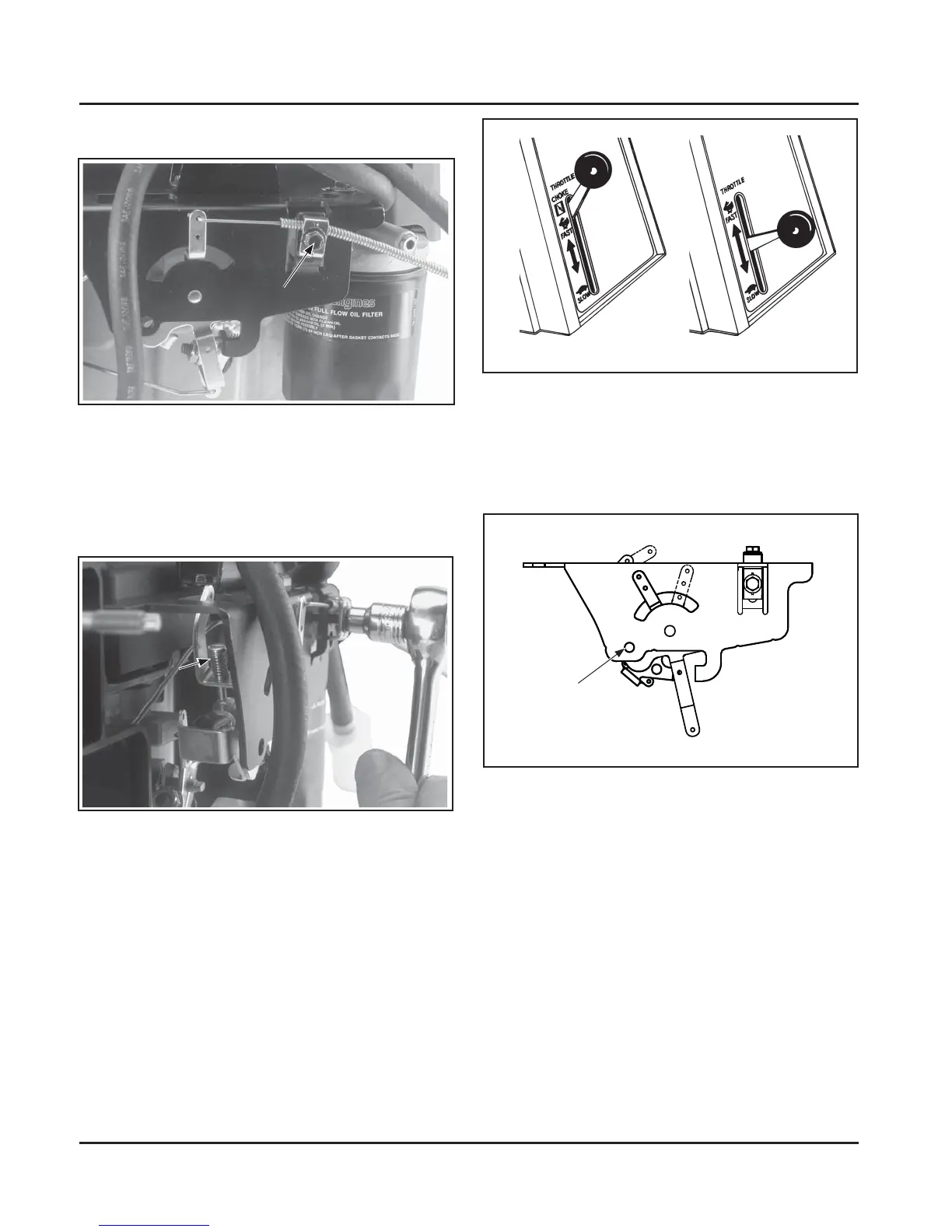

Figure 5-14. Typical Throttle/Choke Controls.

3. Early Models: Early models use a single

alignment hole to set the engine RPM. Align

the hole in the throle lever with the hole in the

speed control bracket by inserting a pencil or 6.35

mm (1/4 in.) drill bit. See Figure 5-15.

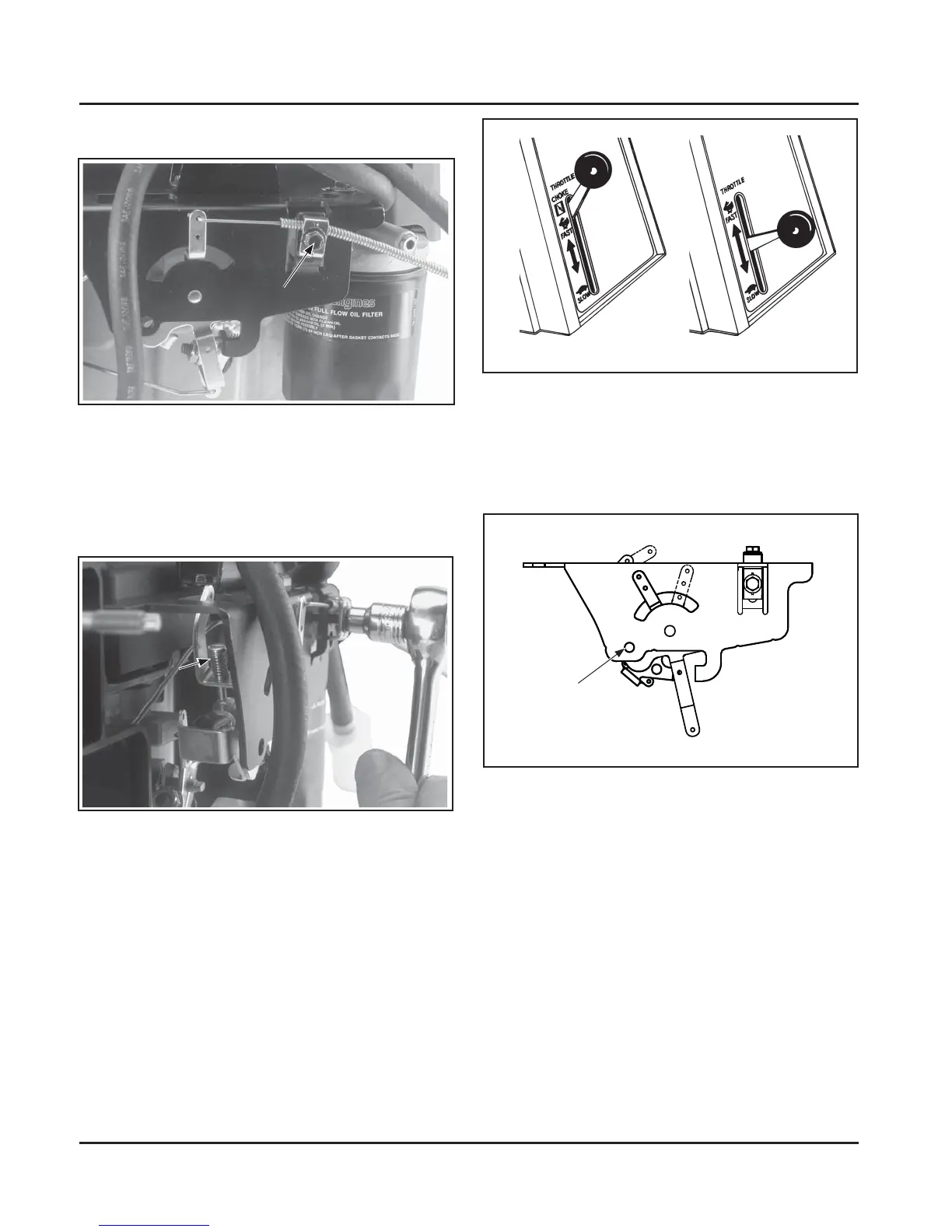

Figure 5-12. Speed Control Bracket with Unitized

Throttle/Choke Control.

2. Place the throle control lever of the equipment

into the fast or high speed position. The actuating

tab+ of the choke lever should be just below the

end of the choke adjusting screw. See Figure 5-13.

Figure 5-15. Alignment Hole in Speed Control

Bracket and Throttle Lever. (Early Models)

Later Models: Later models use a new control

assembly, identified by two opposing alignment

holes (close to the throle lever pivot), instead of

one. Based upon the intended high-speed (RPM)

seing, throle cable adjustment must be made

by matching the hole in the control lever with the

correct alignment hole. Use the lower (le side)

hole for high-speed seings above 3000 RPM. Use

the upper (right side) hole for high-speed seings

lower than 3000 RPM. Move the throle lever to

align the hole in the lever with the correct hole in

the control bracket. Insert a pencil or a 6.35 mm

(1/4 in.) drill bit to hold in position. See Figure

5-16.

Cold Engine

Warm Engine

Choke

Adjustment

Screw

Alignment Hole

Throttle Cable Adjustment

1. Loosen the control cable clamp. See Figure 5-12.

Cable

Clamp

Figure 5-13Adjusting Unitized Throttle/Choke

Control.

NOTE: The choke is placed on by moving the

throle control slightly past the fast

position. If the throle control does not

have a designated choke on position, be

sure to leave sufficient throle control

travel past the fast position. This will

enable the choke to be placed on. See

Figure 5-14.

Loading...

Loading...