5.2

Section 5

Fuel System and Governor

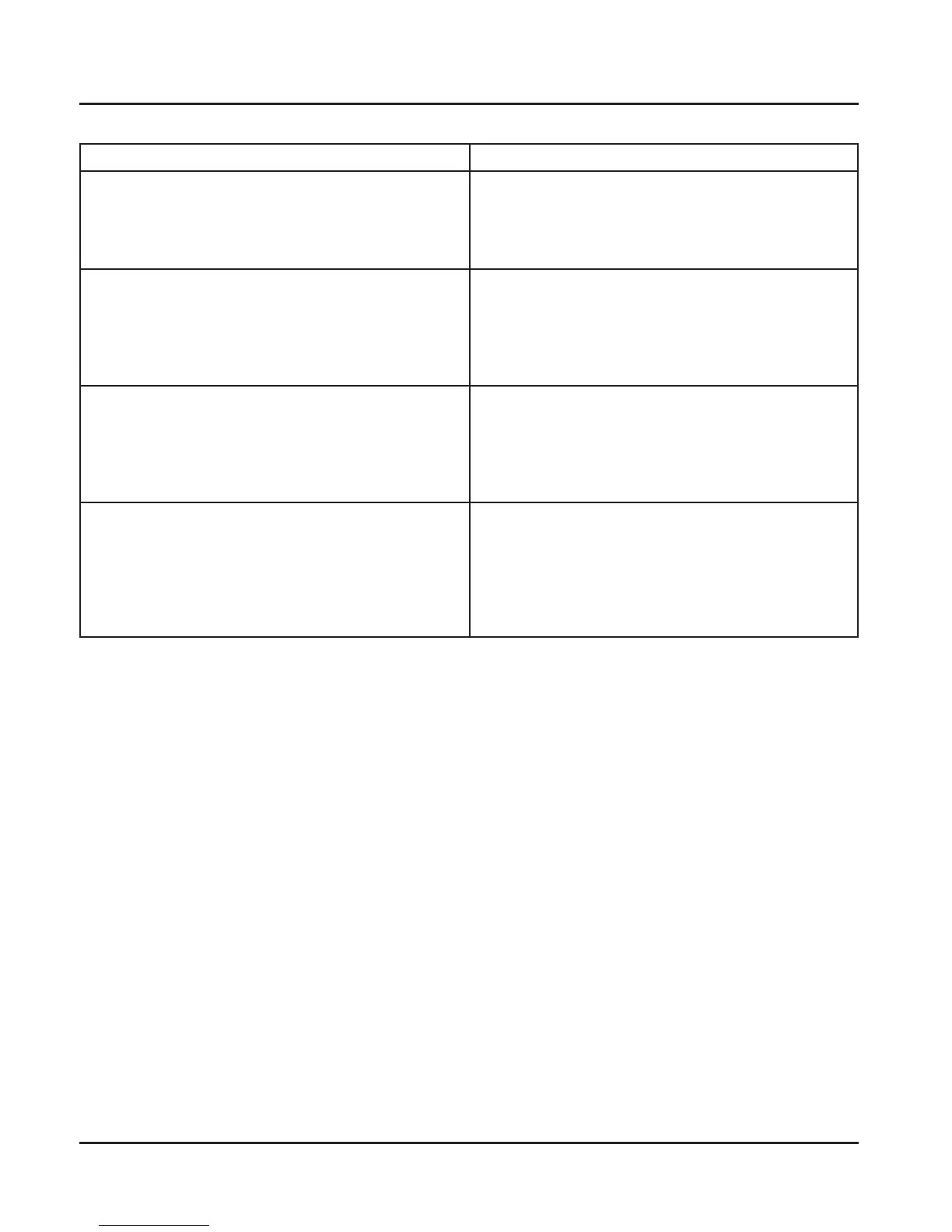

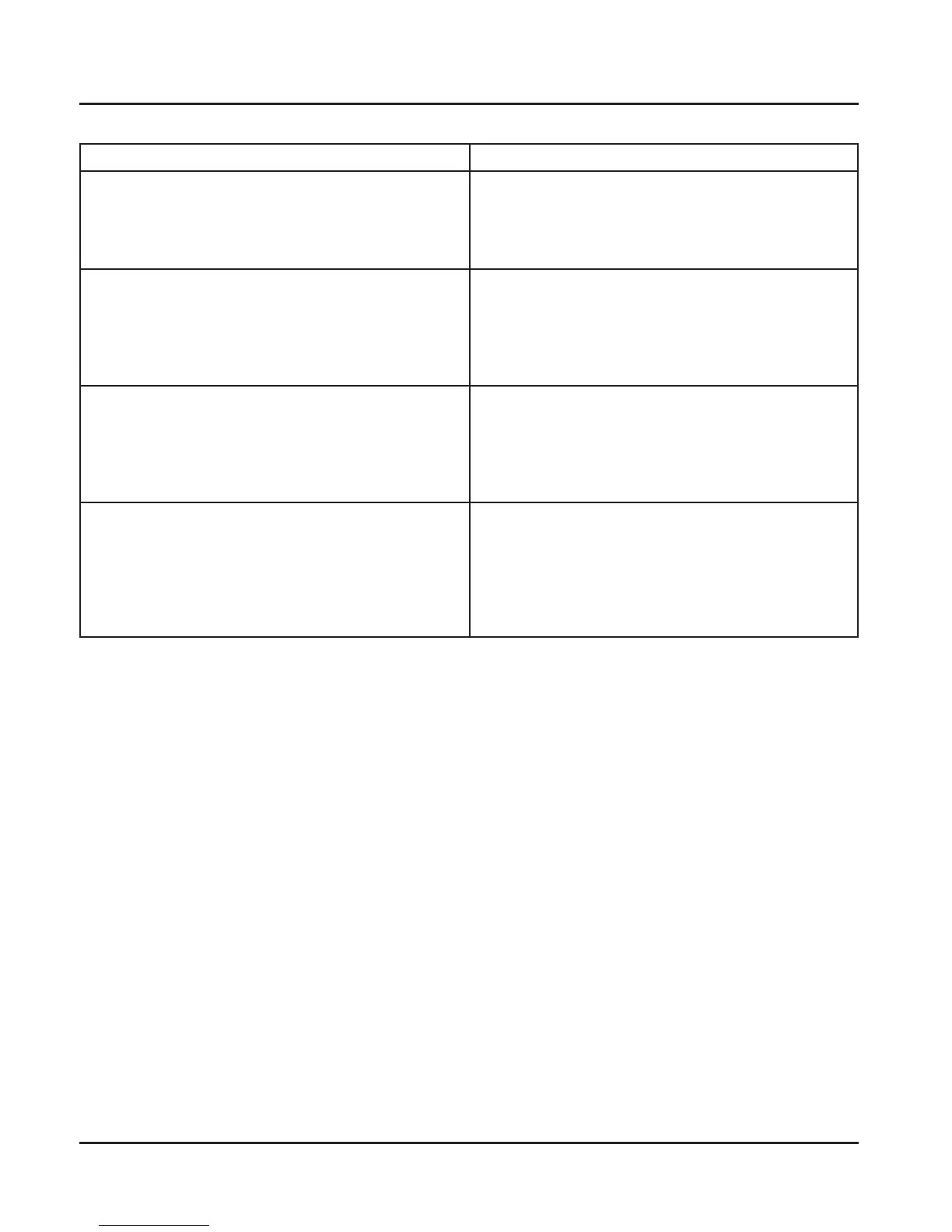

Fuel System Troubleshooting Guide

Test Conclusion

1. Check for the following:

a. Make sure the fuel tank contains clean, fresh,

proper fuel.

b. Make sure the vent in fuel cap is open.

c. Make sure the fuel valve is open.

2. Check for fuel in the combustion chamber.

a. Disconnect and ground spark plug lead.

b. Close the choke on the carburetor.

c. Crank the engine several times.

d. Remove the spark plug and check for fuel at

the tip.

2. If there is fuel at the tip of the spark plug, fuel is

reaching the combustion chamber.

If there is no fuel at the tip of the spark plug, check

for fuel flow from the fuel tank (Test 3).

3. Check for fuel flow from the tank to the fuel pump.

a. Remove the fuel line from the inlet fiing of

the fuel pump.

b. Hold the line below the boom of the tank.

Open the shutoff valve (if so equipped) and

observe flow.

3. If fuel does flow from the line, reconnect line and

check for faulty fuel pump (Test 4).

If fuel does not flow from the line, check for

clogged fuel tank vent, fuel pickup screen, shutoff

valve, and fuel lines.

4. Check the operation of fuel pump.

a. Remove the fuel line from the inlet fiing of

the carburetor.

b. Crank the engine several times and observe

flow.

4. If fuel does flow from the line, check for faulty

carburetor. (Refer to the "Carburetor" portions of

this section.)

If fuel does not flow from the line, check for

clogged fuel line. If the fuel line is unobstructed,

the fuel pump is faulty and must be replaced.

Fuel Filter

Some engines are equipped with an in-line fuel filter.

Periodically inspect the filter and replace when dirty.

Replacement is recommended annually or every 100

hours. Use a genuine Kohler filter.

Fuel Line

These engines use low permeation rated fuel lines,

certified to comply with California and U.S. EPA

evaporative emission requirements. Fuel lines that do

not meet these requirements may not be used. Order

replacement hose through a Kohler Service Center.

Fuel Pump

Some engines are equipped with an optional pulse

fuel pump. See Figure 5-1.

Operation

The fuel pump has two internal chambers separated

by a diaphragm. The air chamber is connected to the

engine crankcase by a rubber hose. The fuel chamber

has an inlet from the fuel tank, and an outlet to the

carburetor. The inlet and outlet each have an internal,

one-way check valve.

Alternating negative and positive pressures in the

crankcase activate the pump. When the piston moves

upward in the cylinder, negative pressure (vacuum)

is created in the crankcase and in the air chamber of

the pump. The diaphragm flexes toward the negative

pressure, and the suction draws fuel past the inlet

check valve, into the fuel chamber. Downward

movement of the piston causes a positive pressure

in the crankcase and air chamber, pushing the

diaphragm in the opposite direction, puing pressure

on the fuel. The inlet check valve has now closed, so

the fuel is forced past the outlet check valve, to the

carburetor.

Repair

Pulse fuel pumps are not serviceable and must be

replaced when faulty.

Removal

1. Disconnect the inlet, outlet, and pulse lines

from the fuel pump. Mark the lines for proper

reassembly.

2. Remove the hex flange screws aaching the fuel

pump.

Loading...

Loading...