7.14

Section 7

Electrical System and Components

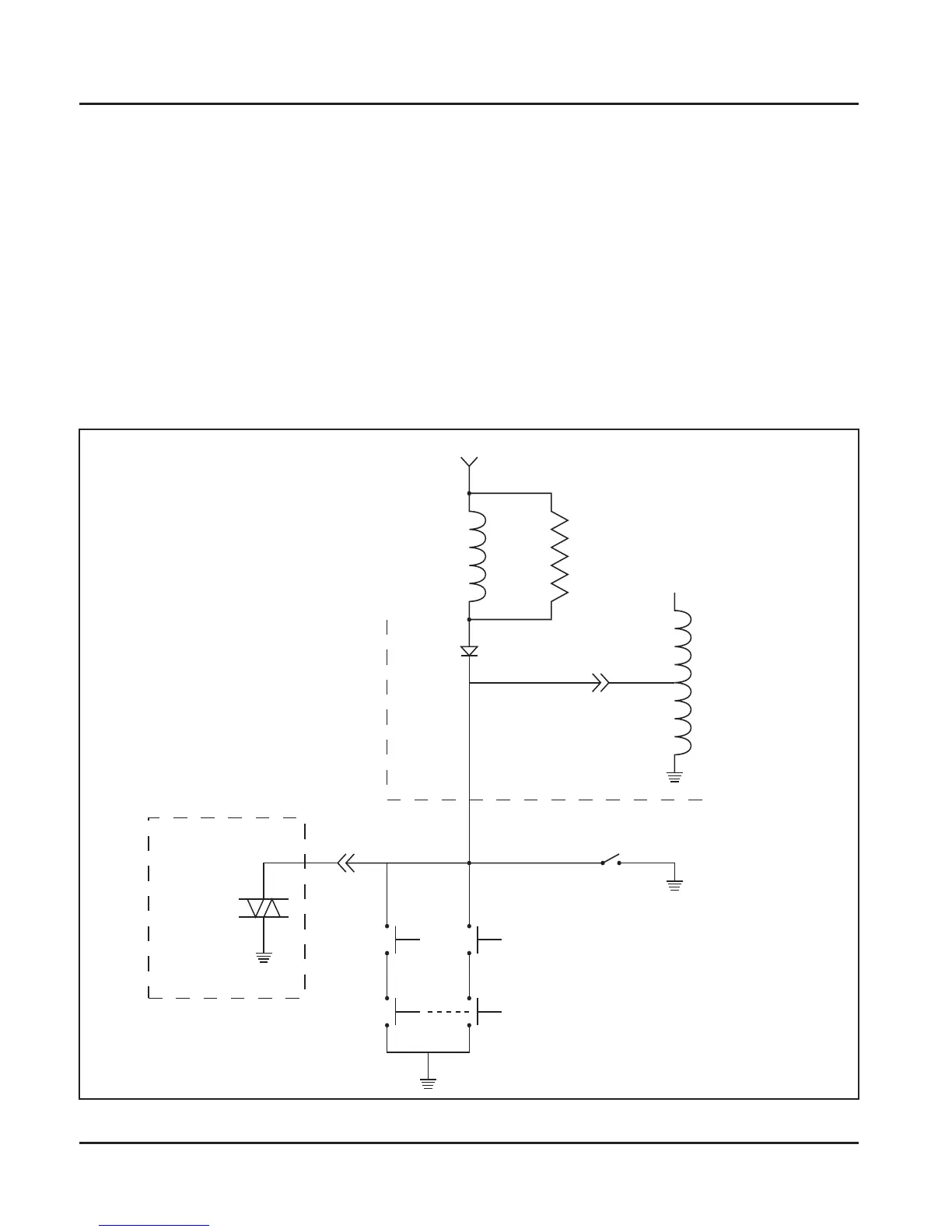

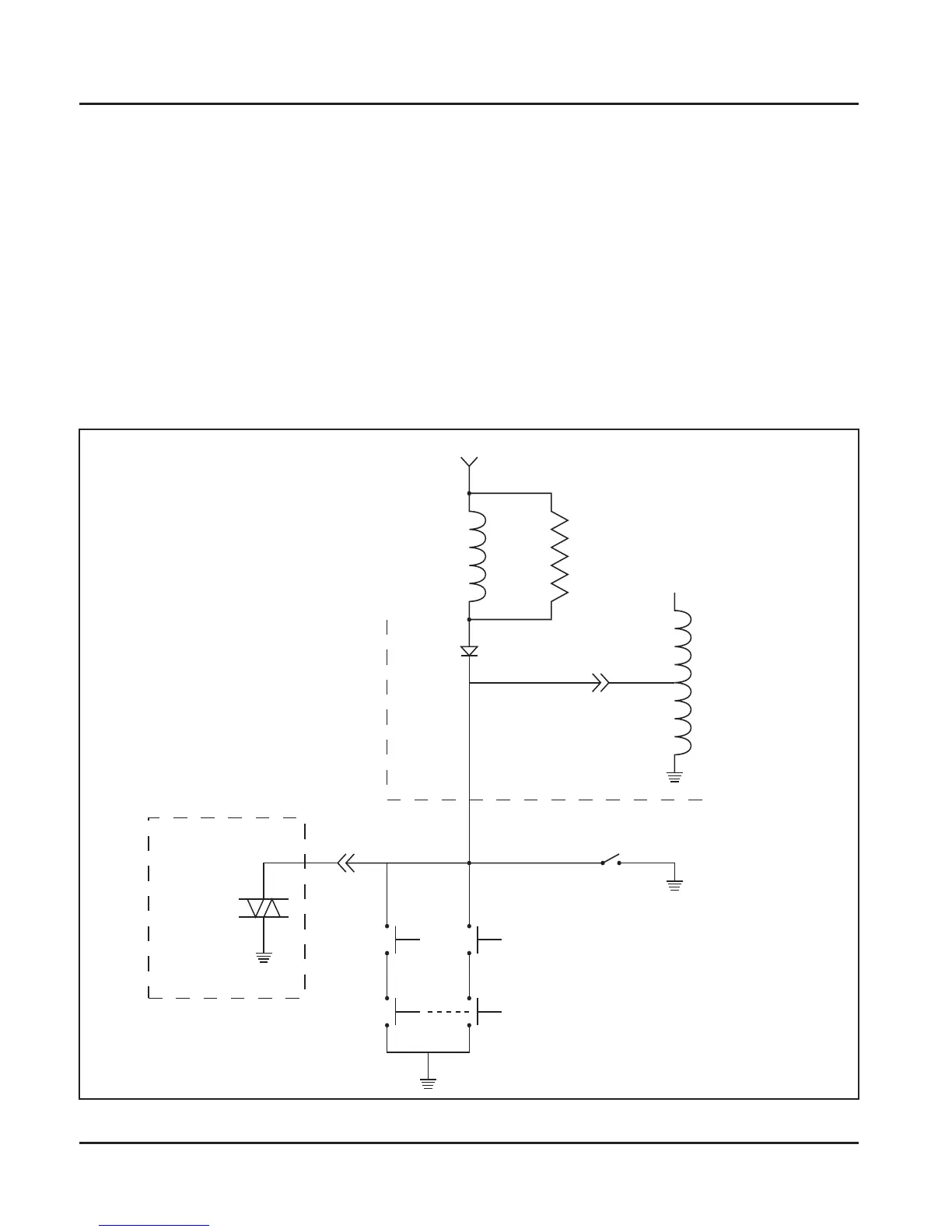

Blade Stop Stator Brake Circuit

The blade stop stator brake circuit is provided as a safety feature to ensure the application can meet ANSI

(American National Standards Institute) application blade stop requirements.

The circuit is activated if the operator gets o of the seat of the application while mower blade system is activated

or in certain reverse mow conditions.

The circuit is activated by taking the ignition shutdown (kill) lead to ground. This action turns on the stator-brake

relay which shorts the charging AC stator leads to produce a magnetic eld that will counter or resist the rotation

of the ywheel. This added resistance to rotation decreases the amount of time it takes for the application deck

blades to come to a full stop.

As the Kohler blade stop stator brake circuit oen is operated in conjunction with other application circuits, the

relay in the Kohler circuit is specially congured with a 680 ohm resistor in parallel with the relay coil. This is

done to negate transient voltage signals that would be normally created by interrupting the relay current once

the relay has been activated. Therefore, relay replacement must only be made with the properly identied relay.

Figure 7-12. Blade Stop Stator Brake Circuit Wiring Diagram.

12V Switched Power

Stator

Brake

Relay

Coil

90 Ω

680 Ω

Engine

Kill

CDI

Ignition

Reverse Mow Module

(OEM Supplied)

TRIAC

NO

PTO

NO

Seat

NC

Brake

NC

Key Switch

Loading...

Loading...