11.

Drain the coolant in reservoir tank (3).

12.

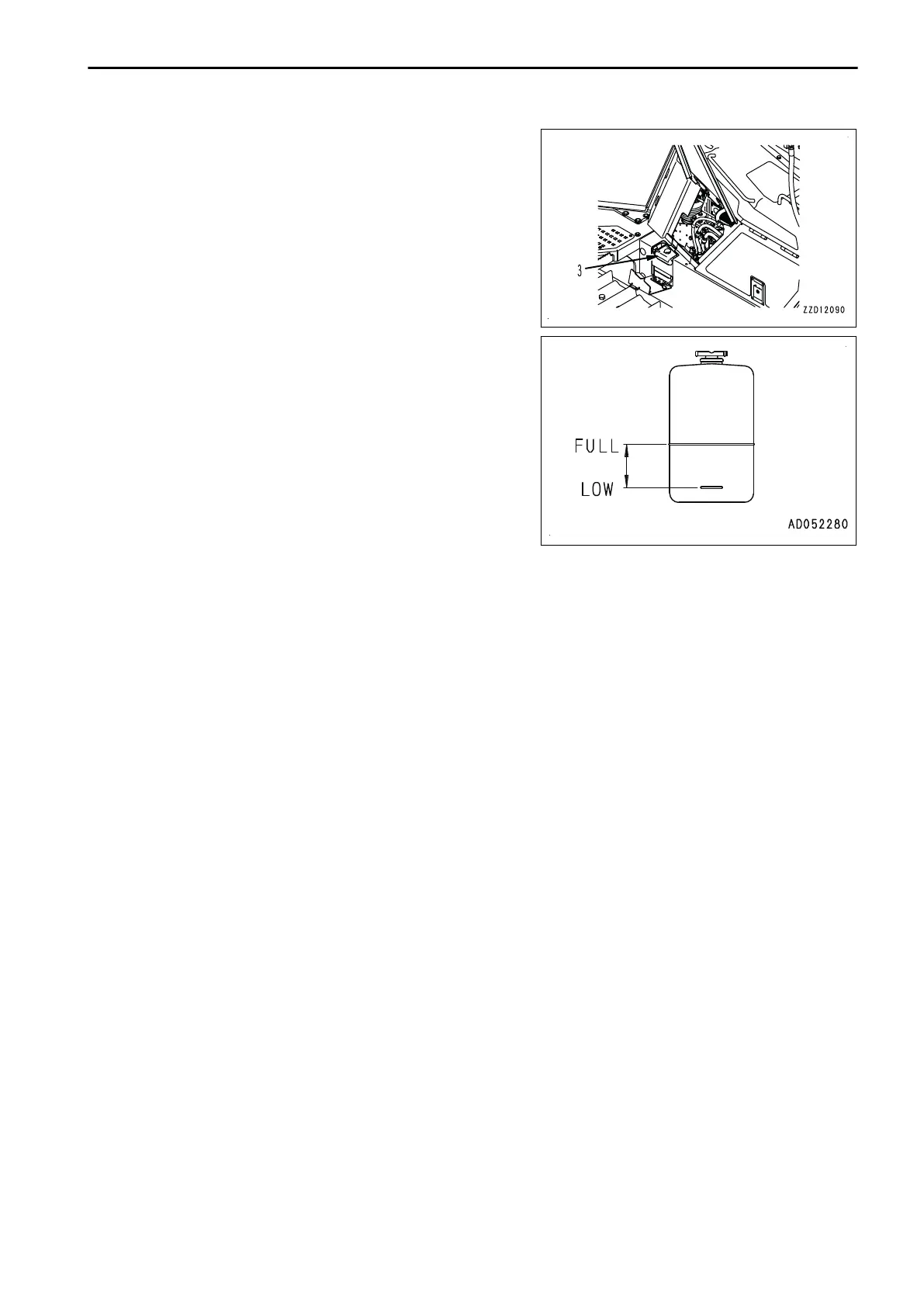

Add Non-Amine Engine Coolant (AF-NAC) up to the mid-

dle between FULL and LOW of reservoir tank (3).

NOTICE

After replacing Non-Amine Engine Coolant (AF-NAC),

the coolant level of the reservoir tank may largely de-

crease as time passes.

If the machine is operated while the coolant level is

low, serious failures such as breakage of EGR cooler

and seizure of the engine inside may be caused. Espe-

cially before starting the engine on the next day of re-

placement, perform “METHOD FOR CHECKING COOL-

ANT LEVEL, ADDING COOLANT (3-145)”.

13.

Stop the engine.

14.

After 3 minutes, add Non-Amine Engine Coolant (AF-NAC) up to the mouth of the coolant filler port (1).

Add all the specified volume of Non-Amine Engine Coolant (AF-NAC).

If the refilled coolant amount is below the specified volume, the air bleeding from the coolant is insufficient.

Start the engine and perform air bleeding again by referring the steps 9. and 10.

15.

Tighten cap (1) of radiator coolant filler port.

METHOD FOR CHECKING AND ADJUSTING TRACK TENSION

The wear of the pins and bushings of the undercarriage depends on the working condition and soil conditions.

Check the track tension occasionally and keep it at the standard level.

Perform check and adjustment on a level and firm ground.

MAINTENANCE MAINTENANCE PROCEDURE

4-23

Loading...

Loading...