1-S37

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

ENGINE

[4] SERVICING

(1) Cylinder Head and Valves

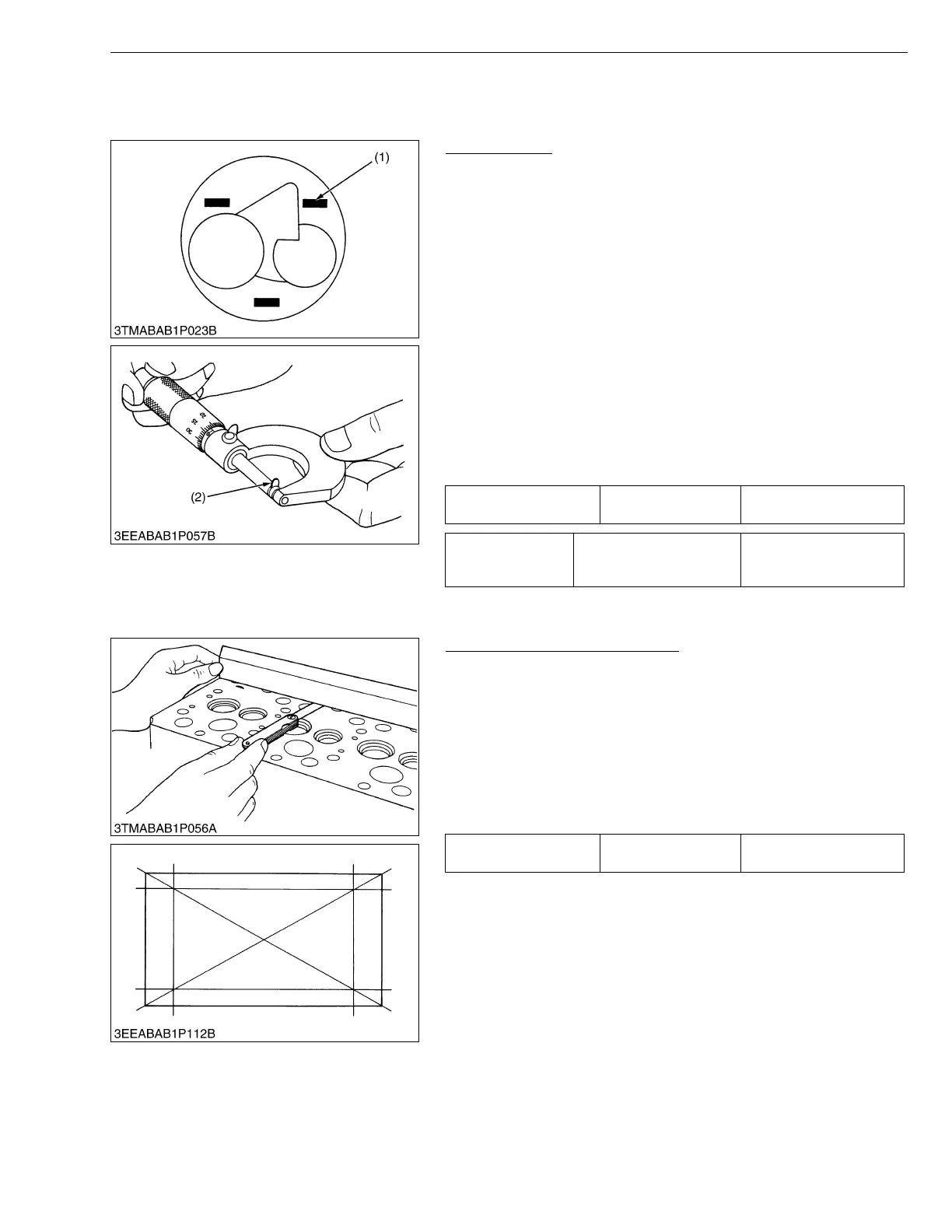

Top Clearance

1. Remove the cylinder head. (Do not attempt to remove the

cylinder head gasket.)

2. Move the piston up and stick a strip of fuse [1.5 mm dia. (0.059

in. dia.), 5 to 7 mm long (0.197 to 0.276 in. long)] on the piston

head at three positions with grease so as to avoid the intake and

exhaust valves and the combustion chamber ports.

3. Lower the piston, and install the cylinder head and tighten the

cylinder head screws to the specified torque.

4. Turn the flywheel until the piston passes top dead center.

5. Remove the cylinder head, and measure the thickness of the

squeezed fuses.

6. If the measurement is not within the factory specifications, check

the oil clearance between the crankpin and crankpin bearing and

between the piston pin and small end bushing.

■

• After checking the top clearance, be sure to assemble the

cylinder head with a new cylinder head gasket.

W1020190

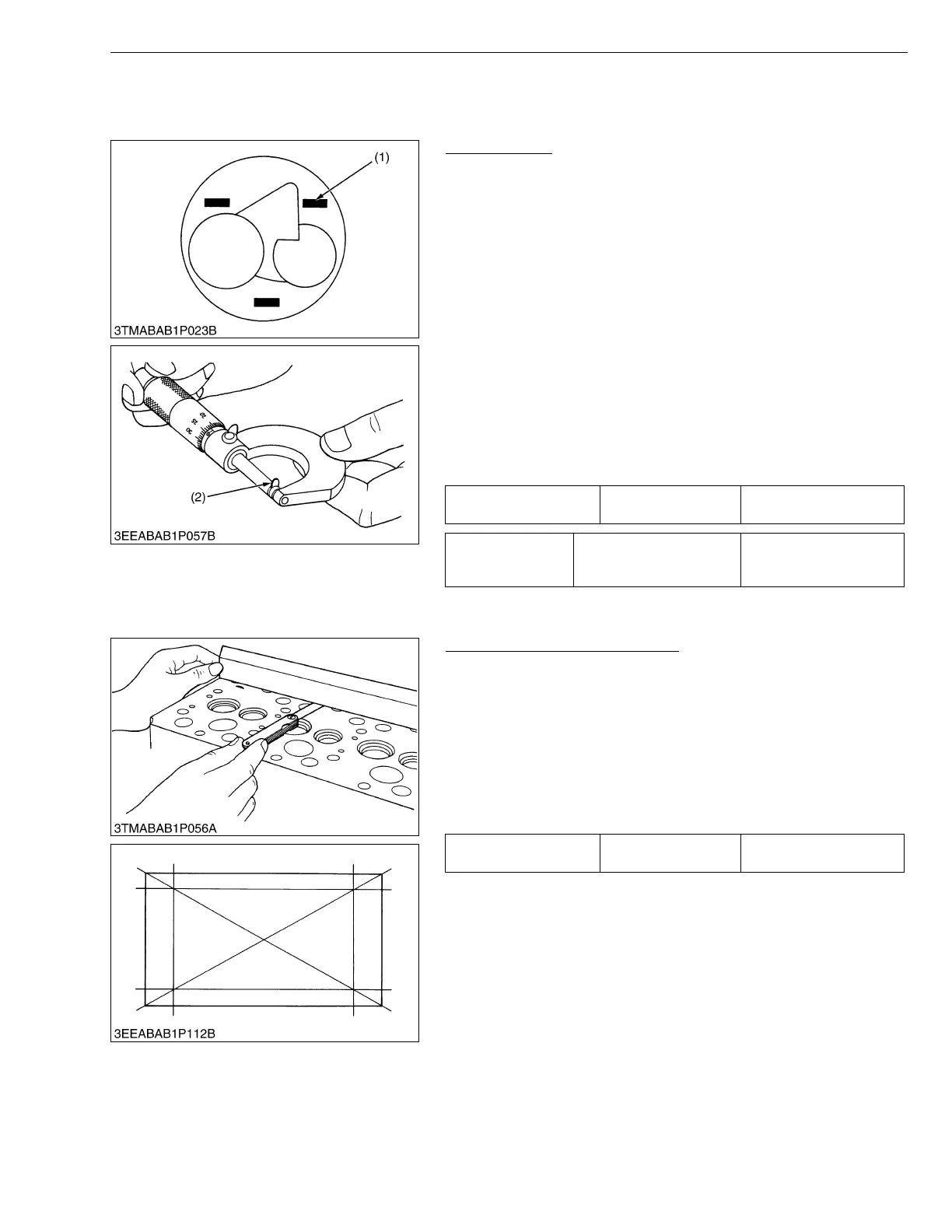

Cylinder Head Surface Flatness

1. Clean the cylinder head surface.

2. Place a straightedge on the cylinder head’s four sides and two

diagonal as shown in the figure.

3. Measure the clearance with a thickness gauge.

4. If the measurement exceeds the allowable limit, correct it with a

surface grinder.

■

• Do not place the straightedge on the combustion chamber.

• Be sure to check the valve recessing after correcting.

W1027737

Top clearance Factory spec.

0.55 to 0.70 mm

0.0217 to 0.0276 in.

Tightening torque Cylinder head screws

63.7 to 68.6 N·m

6.5 to 7.0 kgf·m

47.0 to 50.6 ft-lbs

(1) Fuse (2) Fuse

Cylinder head surface

flatness

Allowable limit

0.05 mm

0.0020 in.

Loading...

Loading...