2-M18

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

TRANSMISSION

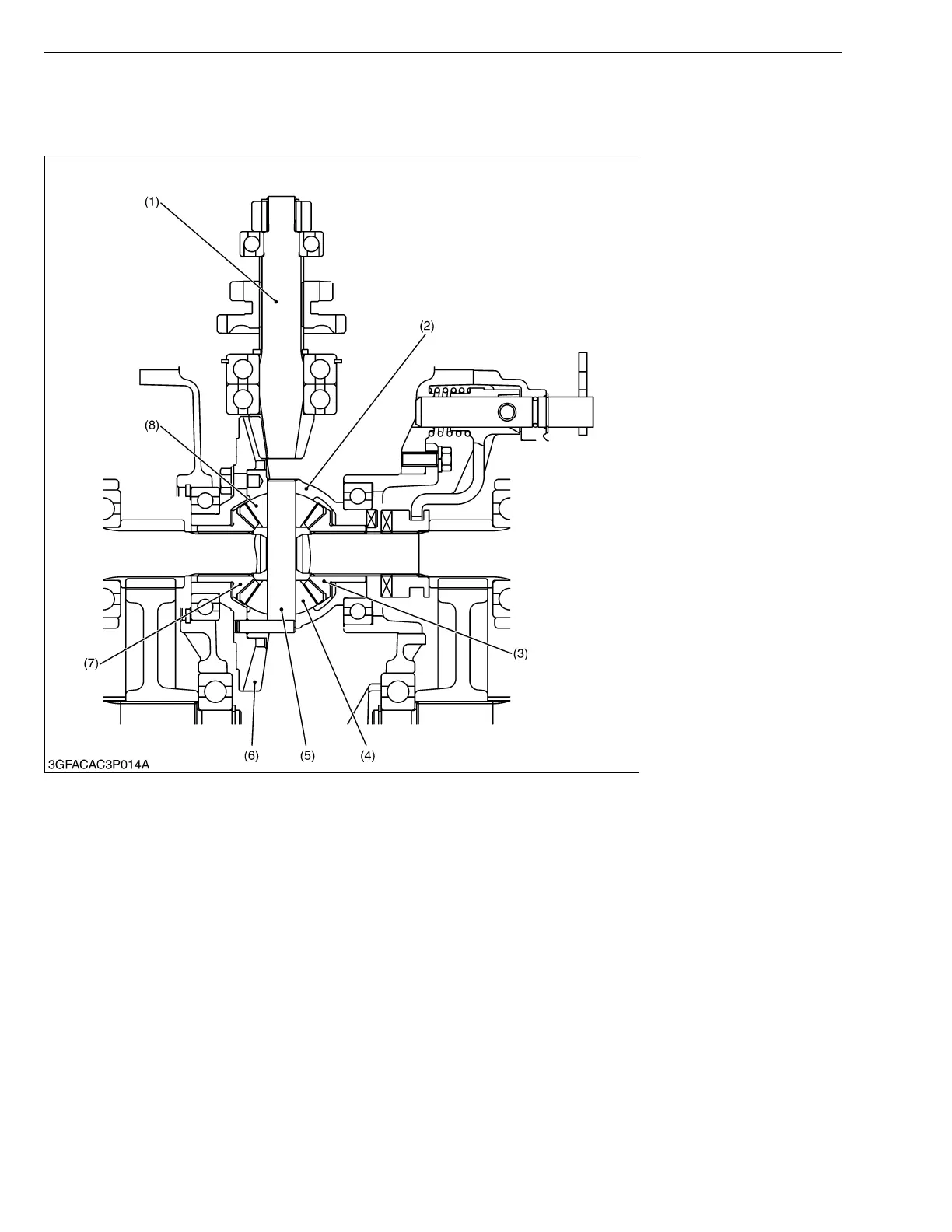

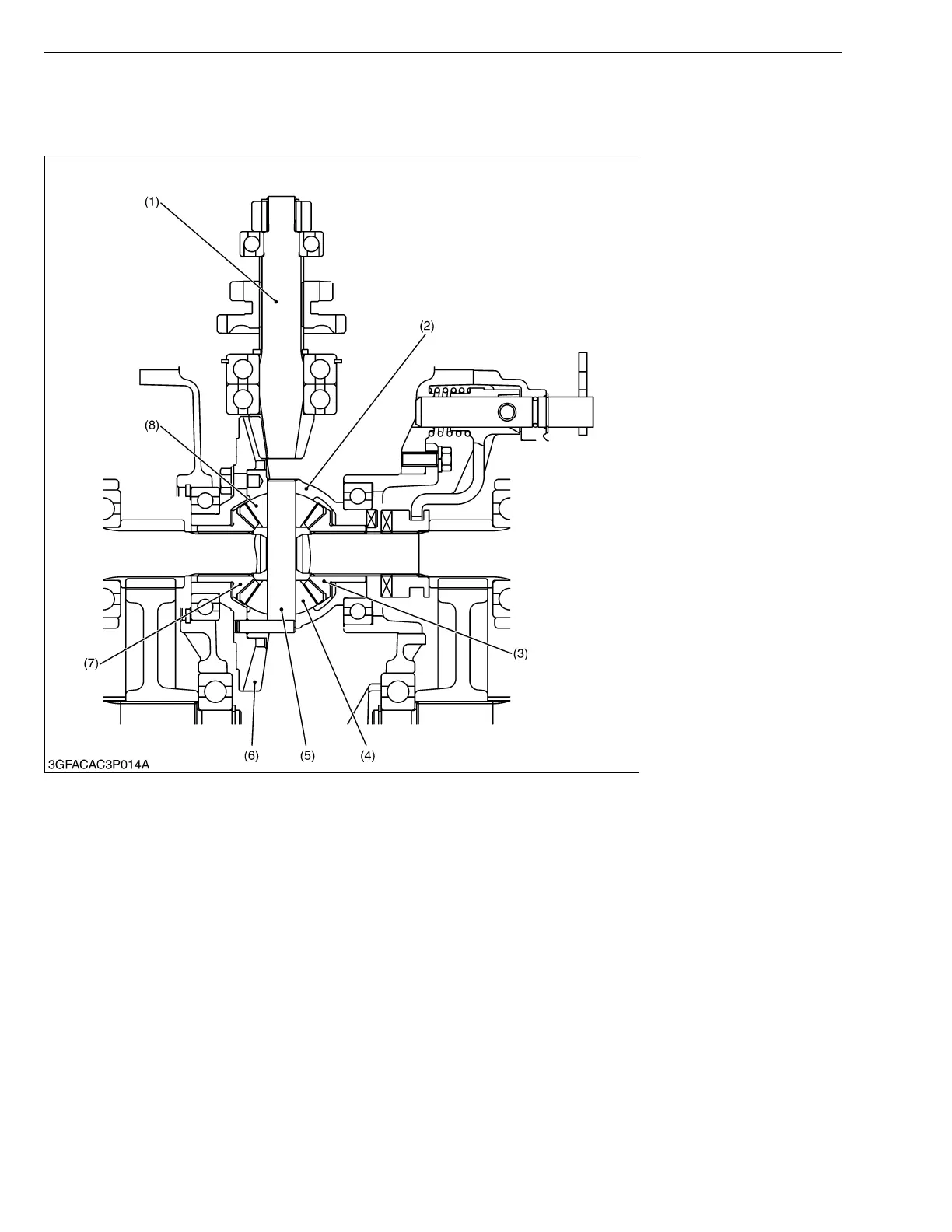

6. DIFFERENTIAL GEAR SECTION

[1] DIFFERENTIAL FUNCTION

W1017697

1. During Straight Running

Rotation of the bevel pinion shaft (1) is transmitted to the spiral bevel gear (6) and differential case (2).

When road resistance to the right and left wheels are equal, differential pinions (4), (8) and differential side gears

(3), (7) are all rotate as a unit. Both front axles received equal input, and both wheels turn at the same speed, allowing

the machine to go straight ahead.

At this time, differential pinions (4), (8) do not rotate around the differential pinion shaft (5).

2. During Turning

When the machine turns, the road resistance to the inside tire increases (as if braking is applied to that side only).

In other words, if one of tires slows down, revolution difference is generated in the differential side gears (3), (7). When

rotation of one differential side gear becomes lower than the other, differential pinions (4), (8) begin rotating around

differential pinion shaft (5). The other differential side gear is increased in speed by the speed increment of differential

pinion shaft (5). This means that rotation of one front axle is slowed down and that of the other front axle is increased.

Thus, the machine turns smoothly without power loss.

The combined number of revolutions of the right and left differential side gears (3), (7) is always twice that of the

spiral bevel gear (6). When spiral bevel gear revolution is 100 min

-1

(rpm), and if one of the differential side gears

stops moving, the revolution of the other differential side gear becomes 200 min

-1

(rpm) and if one rotates at

50 min

-1

(rpm), the other rotates at 150 min

-1

(rpm)

(1) Bevel Pinion Shaft

(2) Differential Case

(3) Differential Side Gear

(4) Differential Pinion Gear

(5) Differential Pinion Shaft

(6) Spiral Bevel Gear

(7) Differential Side Gear

(8) Differential Case

Loading...

Loading...