9-S22

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

MOWER

[4] SERVICING

Checking Torque of Pinion Shaft

■

• Do not remove the mower belt.

1. Wind a string around the pinion shaft and set a push-pull gauge

to the end of the string, and then slowly pull the push-pull gauge

horizontally to measure the turning force.

2. If the measurement exceeds the factory specification, check the

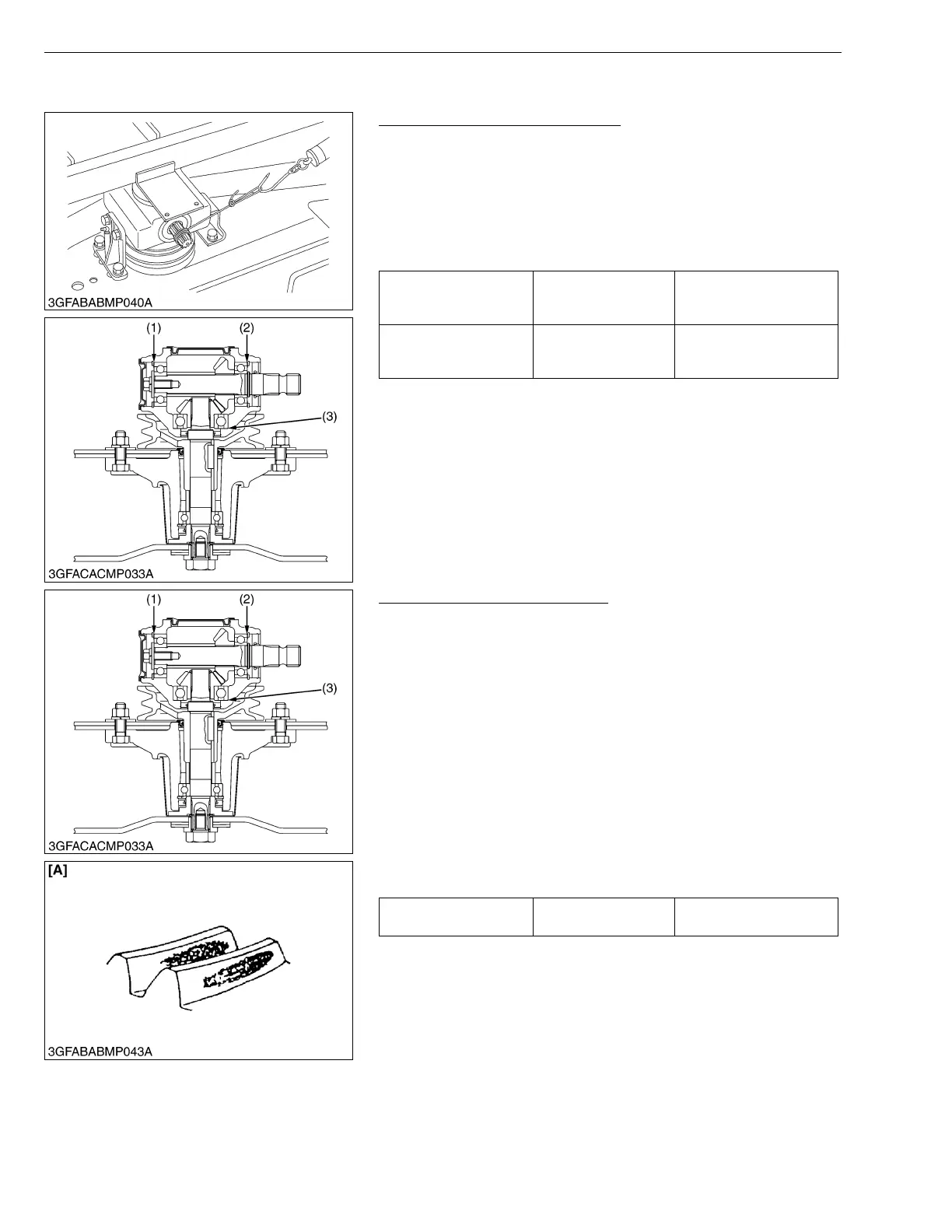

bearing and gears and adjust the adjusting shims (1), (2), (3).

(Reference)

• Thickness of adjusting shims (1), (2) : 0.2 mm (0.0079 in.)

0.3 mm (0.0118 in.)

• Thickness of adjusting shims (3) : 0.1 mm (0.0039 in.)

0.2 mm (0.0079 in.)

W1024471

Backlash between Bevel Gears

1. Remove the gear box cap.

2. Place fuses the bevel gear on the pinion shaft.

3. Turn the pinion shaft.

4. Take out the fuses, and measure the thickness of fuses with an

outside micrometer. (Backlash equal thickness of fuse)

5. If the backlash is not within the factory specifications, adjust with

shims (1), (2), (3).

6. Apply red lead lightly over several teeth at three positions equally

spaced on the bevel gear.

7. Turn the pinion shaft.

8. Check the tooth contact. If not correct, adjust with shim (1), (2),

(3).

■

• After checking the tooth contact, checking the backlash

between pinion shaft and bevel gear again.

(Reference)

• Thickness of adjusting shims (1), (2) : 0.2 mm (0.0079 in.)

0.3 mm (0.0118 in.)

• Thickness of adjusting shims (3) : 0.1 mm (0.0039 in.)

0.2 mm (0.0079 in.)

W1024912

Turning force Factory spec.

490 N

Less than 50 kgf

110 lbs

Turning torque Factory spec.

5.9 N·m

Less than 0.6 kgf·m

4.3 ft-lbs

(1) Shim

(2) Shim

(3) Shim

Backlash between bevel

gears

Factory spec.

0.13 to 0.25 mm

0.0052 to 0.0098 in.

(1) Shim

(2) Shim

(3) Shim

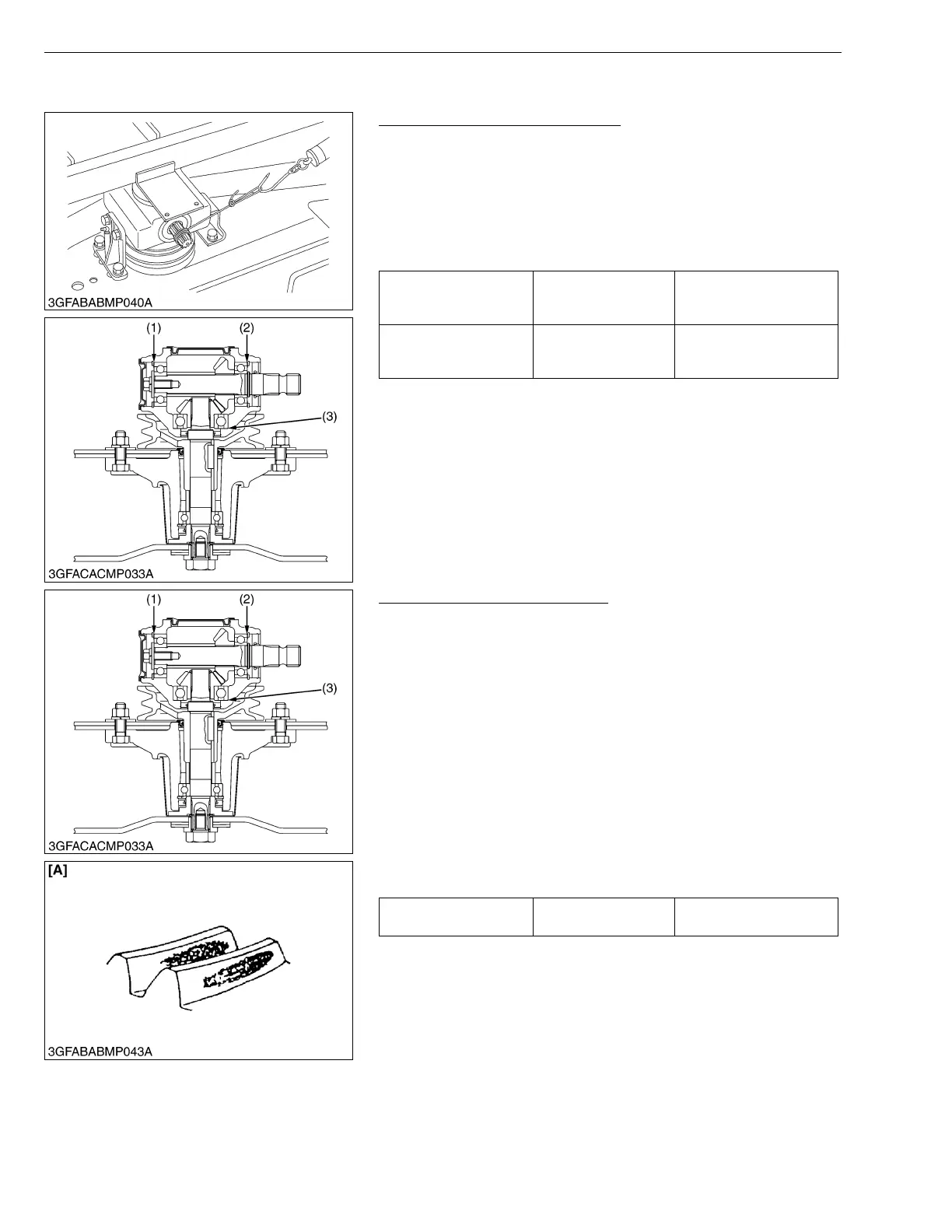

[A] Correct Contact :

More than 35 % red lead contact

area on the gear tooth surface.

The center of tooth contact at 1/3

of the entire width from the small

end.

Loading...

Loading...