14 ENGLISH

NOTE:Dependingontheconditionsofuseandthe

ambienttemperature,theindicationmaydifferslightly

fromtheactualcapacity.

Automatic speed change function

NOTE:Automaticspeedchangefunctionisonly

availablewhenthespeedadjustingdialisin5.

Thistoolhas"highspeedmode"and"hightorque

mode".

Thetoolautomaticallychangestheoperationmode

depending on the work load. When the work load is low,

thetoolwillruninthe"highspeedmode"forquicker

cutting operation. When the work load is high, the tool

willruninthe"hightorquemode"forpowerfulcutting

operation.

►Fig.10: 1. Mode indicator

Themodeindicatorlightsupingreenwhenthetoolis

runningin"hightorquemode".

Ifthetoolisoperatedwithexcessiveload,themode

indicatorwillblinkingreen.Themodeindicatorstops

blinkingandthenlightsuporturnsoffifyoureducethe

load on the tool.

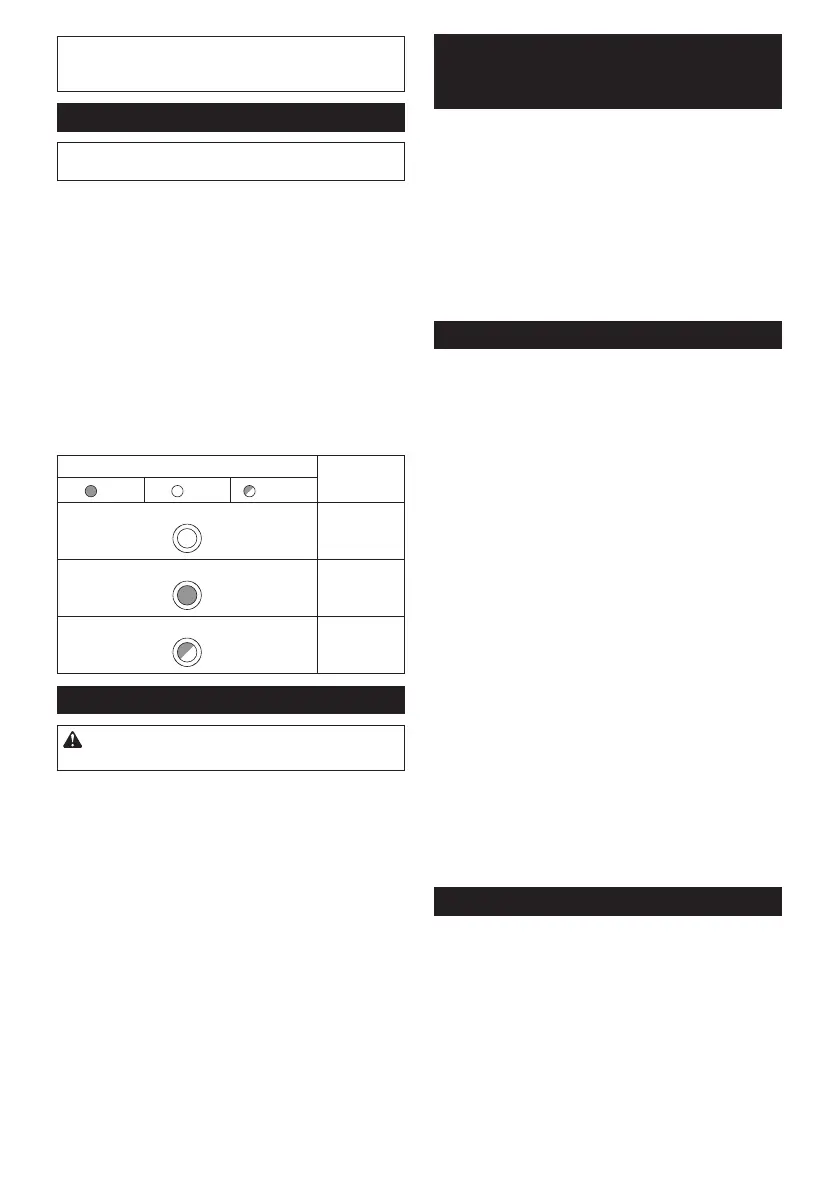

Mode indicator status Operation

mode

On Off Blinking

High speed

mode

Hightorque

mode

Overload

alert

Adjusting depth of cut

CAUTION: After adjusting the depth of cut,

always tighten the clamping screw securely.

Loosen the clamping screw on the depth guide and

move the blade lower limit stopper to the desired depth

onthescaleplate.Atthedesireddepthofcut,tighten

theclampingscrewrmly.

Forcleaner,safercuts,setcutdepthsothatnomore

thanonebladetoothprojectsbelowworkpiece.Using

propercutdepthhelpstoreducepotentialfordanger-

ousKICKBACKSwhichcancausepersonalinjury.

►Fig.11: 1. Blade lower limit stopper 2. Clamping

screw

Quick stop button for 2 to 3 mm

depth of cut when using guide rail

(optional accessory)

Thistoolhasthequickstopbuttonfor2to3mmdepth

ofcutonthegearhousingasidetherearhandlewhen

usingguiderail.Thisisusedwhenavoidingsplinteron

theworkpieceinthecut.Makeapassofthe2to3mm

rstcutandthenmakeanotherpassofusualcut.

►Fig.12: 1. Quick stop button

Toobtainthe2to3mmdepthofcut,pushinthequick

stopbuttontowardthesawblade.Thisisconvenientfor

avoiding splinter on the workpiece.

Toreleasethedepthofcutfromthispositionforfree

depthofcut,justpullthebuttonback.

Bevel cutting

Loosentheclampingscrews.Setforthedesiredangle

by tilting accordingly, then tighten the clamping screws

securely.

►Fig.13: 1. Clamping screw 2. Bevel scale plate

►Fig.14: 1.Subbase(Optionalaccessory)

2. Clamping screw

Positive stopper

Thepositivestopperisusefulforsettingthedesignated

anglequickly.Turnthepositivestoppersothatthe

arrow on it points 22.5°. Loosen the clamping screws

infrontandback.Thentiltthebladeuntilitstopsand

secure the base with the clamping screws.

►Fig.15: 1. Positive stopper 2. Clamping screw

48°-bevel cutting

Toperform48°-bevelcutting,loosentheclamping

screwsandfullytiltthelevertowardthedirectionofthe

arrowinthegure.Thensetthebevelangleto48°and

tighten the clamping screws.

►Fig.16: 1. Lever

-1°-bevel cutting

Toperform-1°-bevelcutting,loosentheclamping

screwsandpresstheleverstowardthedirectionofthe

arrowinthegure.Thensetthebevelangleto-1°and

tighten the clamping screws.

►Fig.17: 1. Lever

Sighting

►Fig.18: 1. Base

Thecuttinglinevariesdependingonthecuttingangle

andwhetheryouusetheguiderail(optionalaccessory).

When using the tool without guide rail

Forstraightcuts,aligntheApositiononthefrontofthe

base with your cutting line. For 45° bevel cuts, align the

B position with it.

When using the tool with guide rail

For both straight cuts and 45° bevel cuts, always align

theApositiononthefrontofthebasewithyourcutting

line.

Loading...

Loading...