Manitowoc Published 05-16-17, Control # 233-03 2-27

999 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

counterweight pins, swing lock, swing brake, travel brakes,

and travel 2-speed. Reconnect all electrical connections

(DIN plugs) that were disconnected for hydraulic system

checks.

1. Drum pawls:

a. Place each drum park switch in on – park and off –

park positions.

b. Observe that each drum pawl engages and

disengages correctly.

2. Counterweight pins:

a. Access setup remote control in left side enclosure.

b. Use counterweight pins switch on remote control to

engage and disengage cylinders several times to

remove air from system.

3. Swing brake and swing lock:

a. Scroll to swing diagnostic screen.

b. With swing park brake and swing lock off, attempt to

swing the crane by moving control handle in both

directions.

c. Crane must respond and indicate on swing screen

that swing park brake and swing lock are released.

4. Travel brakes:

a. Scroll to travel diagnostic screen.

b. With travel park brake off, attempt to travel the

crane by moving control handles in both directions.

c. Crane must respond and indicate on travel screen

that travel park brake is released.

d. Travel 2-speed is checked in test area when travel

speed is checked.

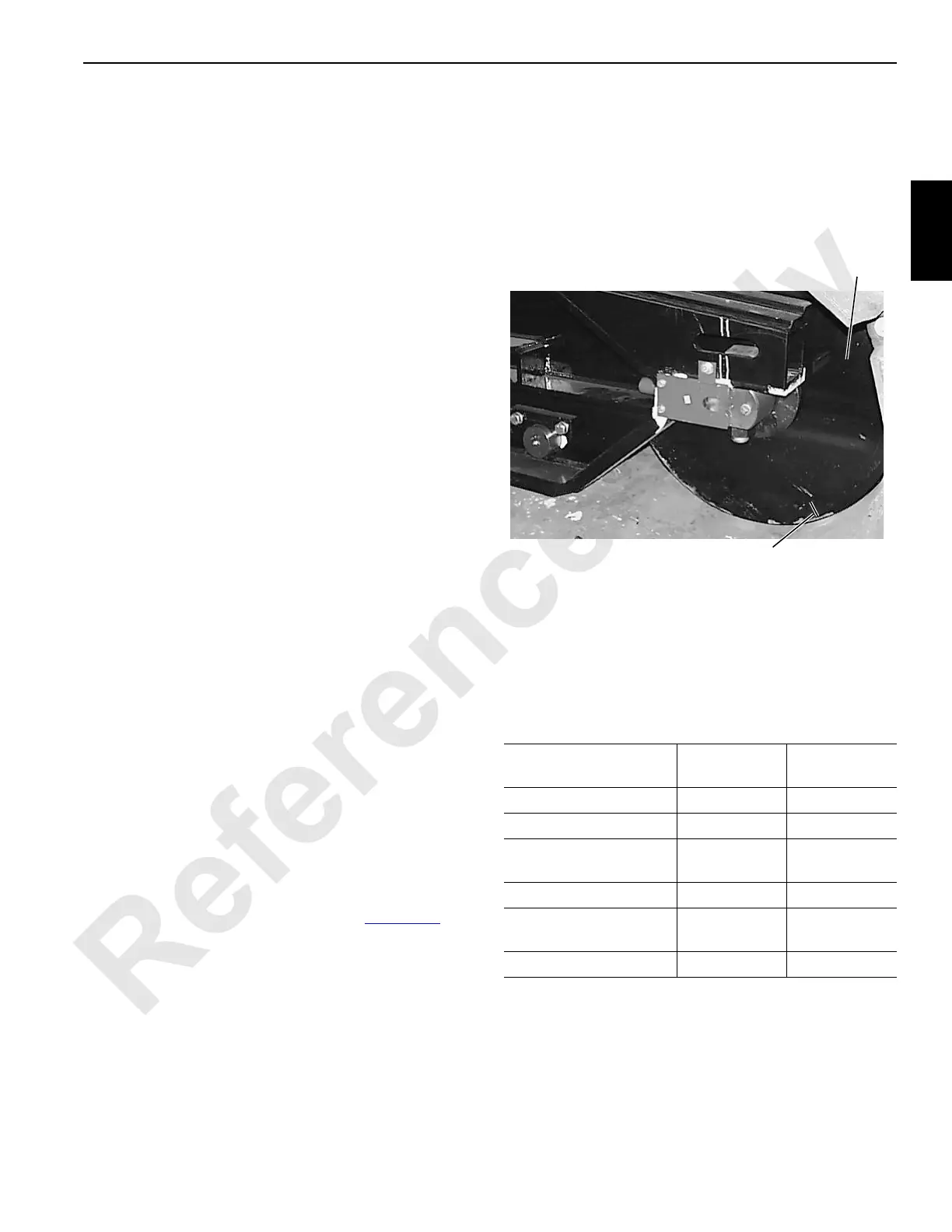

Travel Handle and Speed Check

Verify that travel movement responds correctly to handle

commands. You must count number of revolutions crawler

rotates in one minute to determine travel speed.

NOTE: Final evaluation of travel system is completed in

test area.

1. Put a timing mark on either front roller (Figure 2-24

).

2. Start engine and set speed at high idle.

3. Push both crawler control handles fully forward to travel

crane forward at full speed.

4. Have an assistant count number of revolutions timing

mark makes.

5. Number should be 8-1/2 – 9 revolutions in one minute

(tumbler or idler) or as indicated on Final Checkout/

Assembly and Test form.

6. If count does not fall within this range, determine cause

of problem and take corrective action.

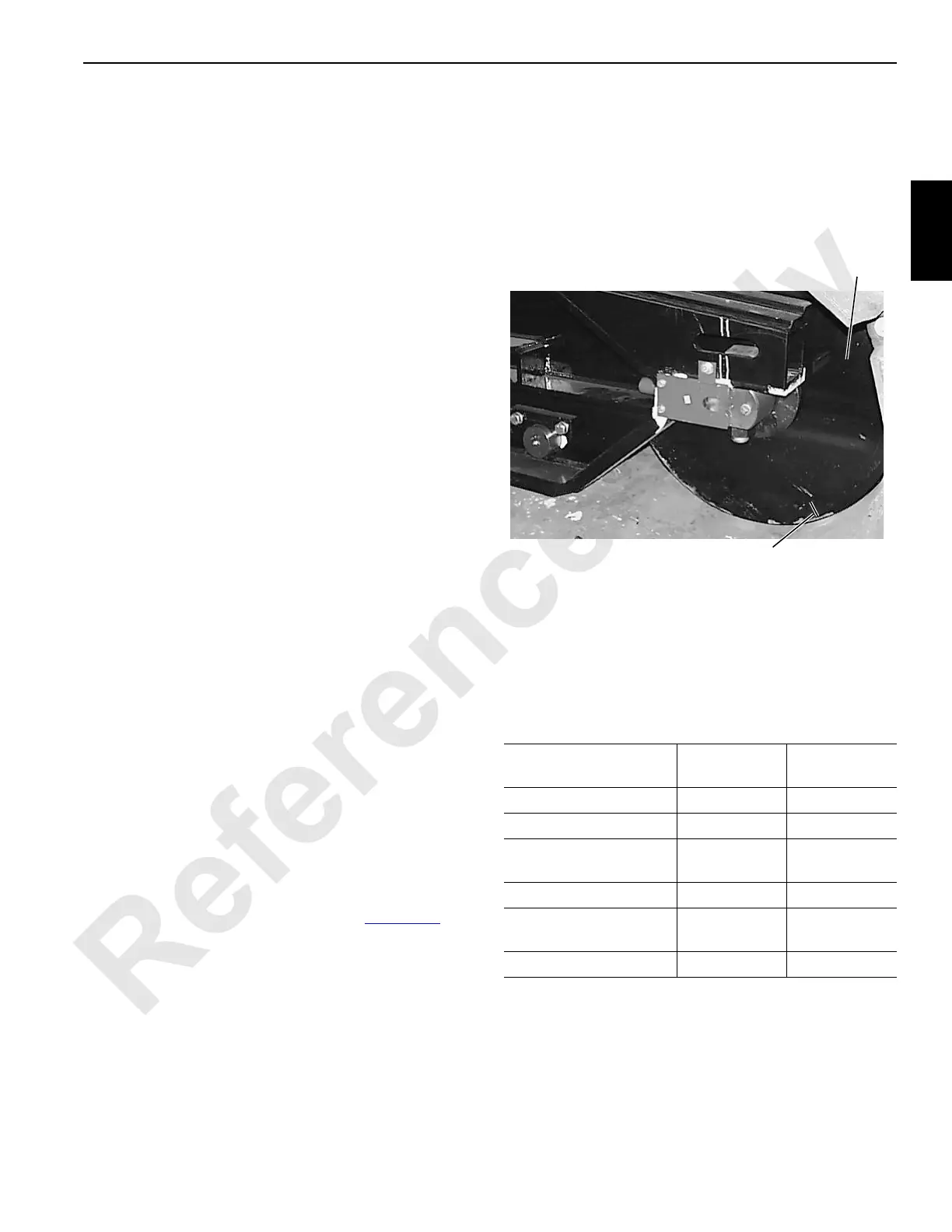

Operating Drum Speed Checks

Check operating speeds for functions listed below with

engine running at high idle and control handles moved fully

forward and back. Read speeds on digital display screen.

If proper speeds are not indicated, determine cause of

problem and take corrective action.

Item

Speed Up

(rpm)

Speed Down

(rpm)

Boom Hoist 39 – 43 34 – 41

Front Drum 43 – 48 38 – 46

Front Drum

(high line speed)

68 – 75 60 – 71

Rear Drum 43 – 48 38 – 46

Rear Drum

(high line speed)

68 – 75 60 – 71

Auxiliary Drum 64 – 71 57 – 67

FIGURE 2-24

Front Roller

P1426

Timing Mark

Loading...

Loading...