TROUBLESHOOTING 999 SERVICE/MAINTENANCE MANUAL

10-54

Published 05-16-17, Control # 233-03

Test 22 – Checking Hydraulic Brake Pressure

The swing brake, swing lock and travel brakes operate off

rear drum low-pressure charge pump pressure. The front

drum brake, rear drum brake, and boom hoist brake operate

off low-pressure side of each closed-loop system. The

auxiliary drum brake operates off auxiliary low-pressure

charge pump pressure.

To check hydraulic brake pressures for swing and travel

systems:

• Engine must be off and power off, with all brakes and

locks engaged.

• Disconnect a rear drum charge pressure line.

• Connect a 0 – 1,000 psi (69 bar) gauge with tee fitting in

charge pressure line.

• Start engine and set throttle at high idle.

• Enable test system brake and check that brake pressure

is 325 – 375 psi (22 – 26 bar). Charge pressure can also

be checked at system diagnostic screen.

• If pressure is not within range, adjust rear drum charge

pressure (see Test 18).

• Remove pressure gauge and replace the charge

pressure line.

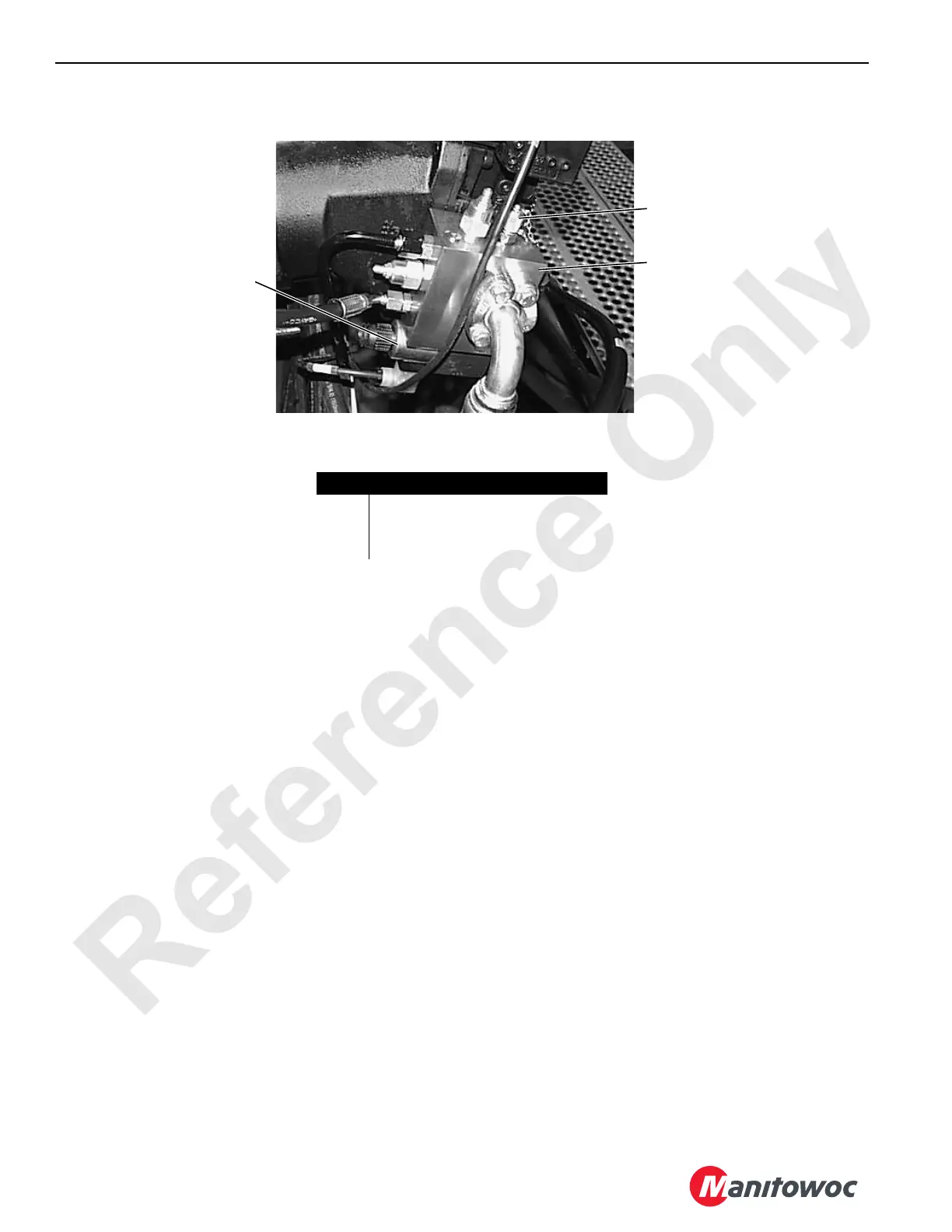

To check hydraulic brake pressure for front drum, rear drum,

or boom hoist system:

• Engine must be off and power off, with all brakes

engaged.

• Connect a 0 – 1,000 psi (69 bar) gauge at diagnostic

gauge coupler on loop flushing valve.

• Start engine and set throttle at high idle (2,000 rpm).

• Enable test system brake and check that brake pressure

is 325 – 375 psi (22 – 26 bar). Charge pressure can also

be checked at system diagnostic screen.

• If pressure is not within range, check system charge

pressure (see Test 18).

• Remove pressure gauge from diagnostic gauge coupler.

To check hydraulic brake pressure for auxiliary drum system:

• Engine must be off and power off, with all brakes

engaged.

• Connect a 0 – 1,000 psi (69 bar) gauge at test port on

auxiliary filter manifold.

• Start engine and set throttle at high idle (2,000 rpm).

• Enable auxiliary drum brake and check that brake

pressure is 325 – 375 psi (22 – 26 bar). Charge pressure

can also be checked at system diagnostic screen.

• If pressure is not within range, check system charge

pressure (see Test 18).

• Remove pressure gauge from test port on auxiliary filter

manifold.

Item Description

1 Diagnostic Gauge Coupler

2 Loop Flushing (purge) Valve

3 Brake Solenoid Valve

Loading...

Loading...