ELECTRIC SYSTEM 999 SERVICE/MAINTENANCE MANUAL

3-42

Published 05-16-17, Control # 233-03

CPU EPROM REPLACEMENT

The central processing unit (CPU) in current production

programmable controllers — to include cranes with a Tier 4

Final engine — no longer has eproms (computer chips).

For information on updating crane software, contact your

Manitowoc dealer or the Manitowoc Crane Lattice Team.

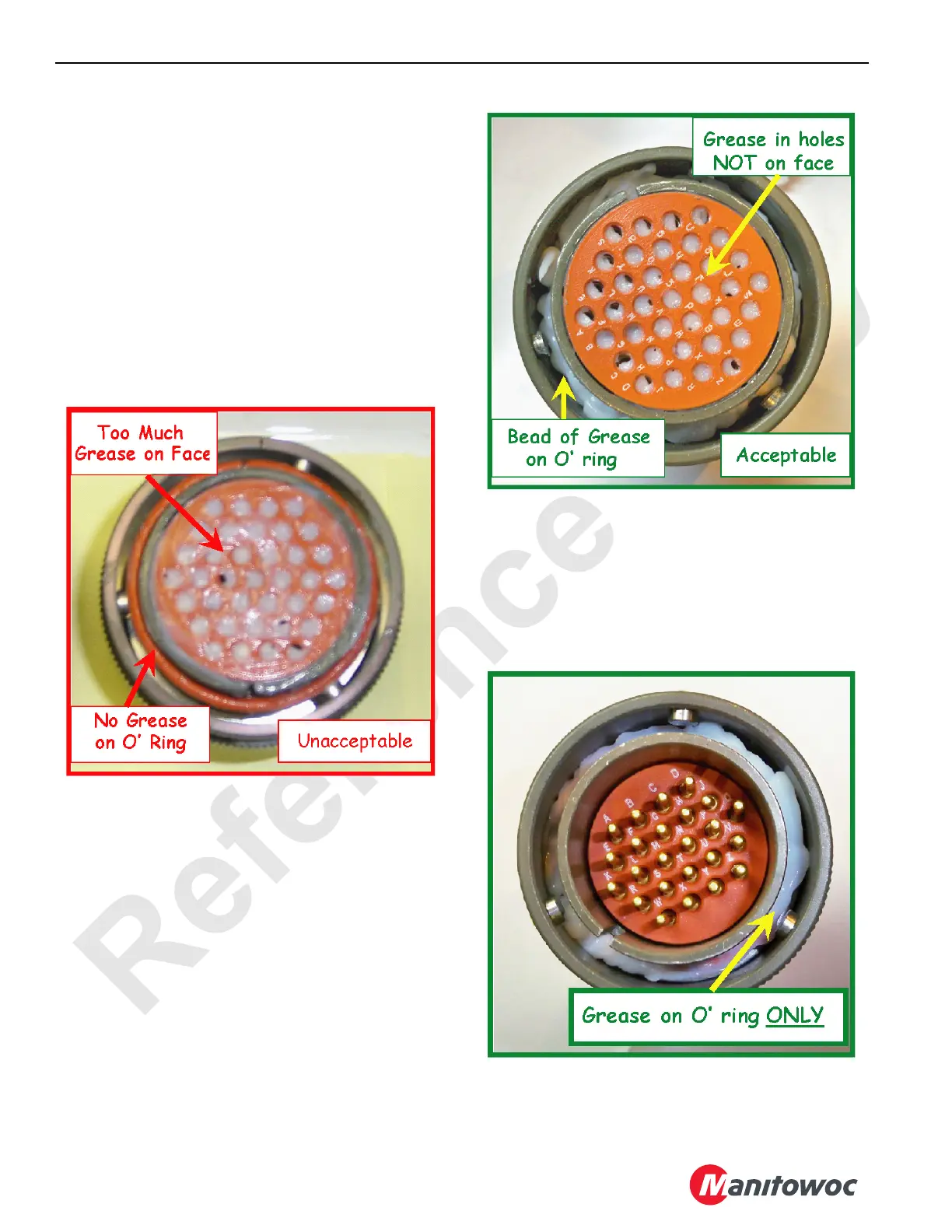

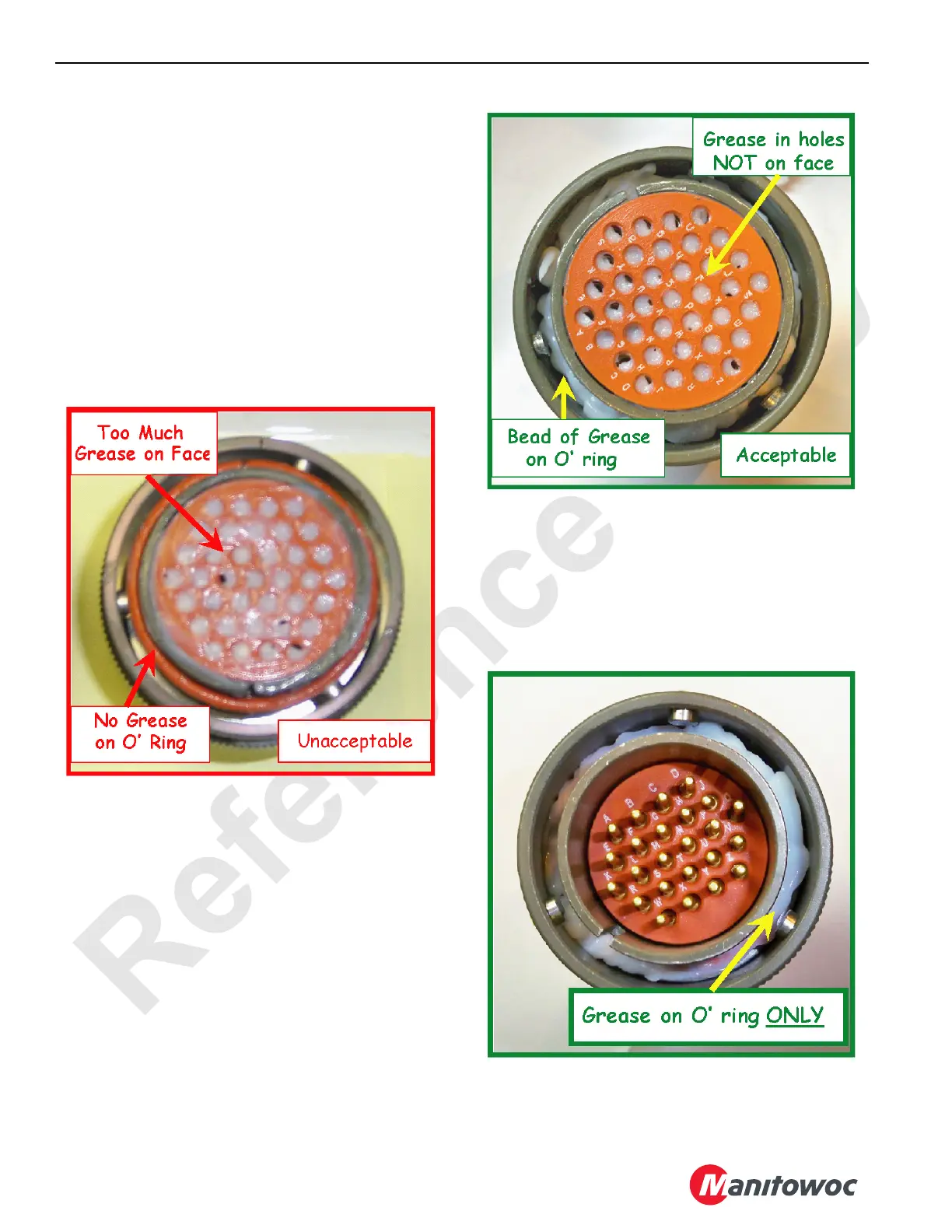

DIELECTRIC GREASE

The following figures show the proper application of

dielectric grease on J-tech type connectors.

Dielectric grease is need when assembling J-tech type

connectors. A bead of grease needs to be applied on O-ring

and face of the socket (female) connector and only on the

O-ring for a pin (male) connector.

The size of the grease bead on the O-ring is as follows:

• On a 3-pin connector a 1/16 inch (1,5 mm) bead is

required.

• On a 24-pin connector a 1/8 inch (3 mm) bead is

required.

• On a 37-pin connector a 3/16 inch (5 mm) bead is

required.

Place a small amount of grease on your finger for the

application on the connector’s face. Wipe your finger across

the face leaving grease inside the socket holes and less than

0.001 inch (0,025 mm) on the connector’s face. This helps

assure that water will be kept out of the connectors and keep

the pins from fretting.

Loading...

Loading...