Manitowoc Published 05-16-17, Control # 233-03 2-15

999 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

Pump Pressure

The pump pressure screen (Figure 2-12) cycles through the

hoist pumps to make sure each pump is capable of

producing 6,000 psi (414 bar).

CAUTION: Only perform this high pressure test when

absolutely necessary and by a qualified service technician.

To check pump pressure calibration, proceed as follows:

1. Access calibration screen (see Accessing Calibration

Screens).

2. Turn PARK ON for all crane functions (drums, boom

hoist, swing, travel).

3. Start engine and run at:

• HIGH IDLE, field personnel.

• 1,500 rpm, MCC assembly personnel when

checking out a new crane.

Testing will not start if engine is not running

faster than 900 rpm.

NOTE: Pump pressure test will not start if engine is not

running. Testing will stop if engine speed is

decreased during procedure.

4. When testing starts, the percent (%) of completion is

displayed on screen.

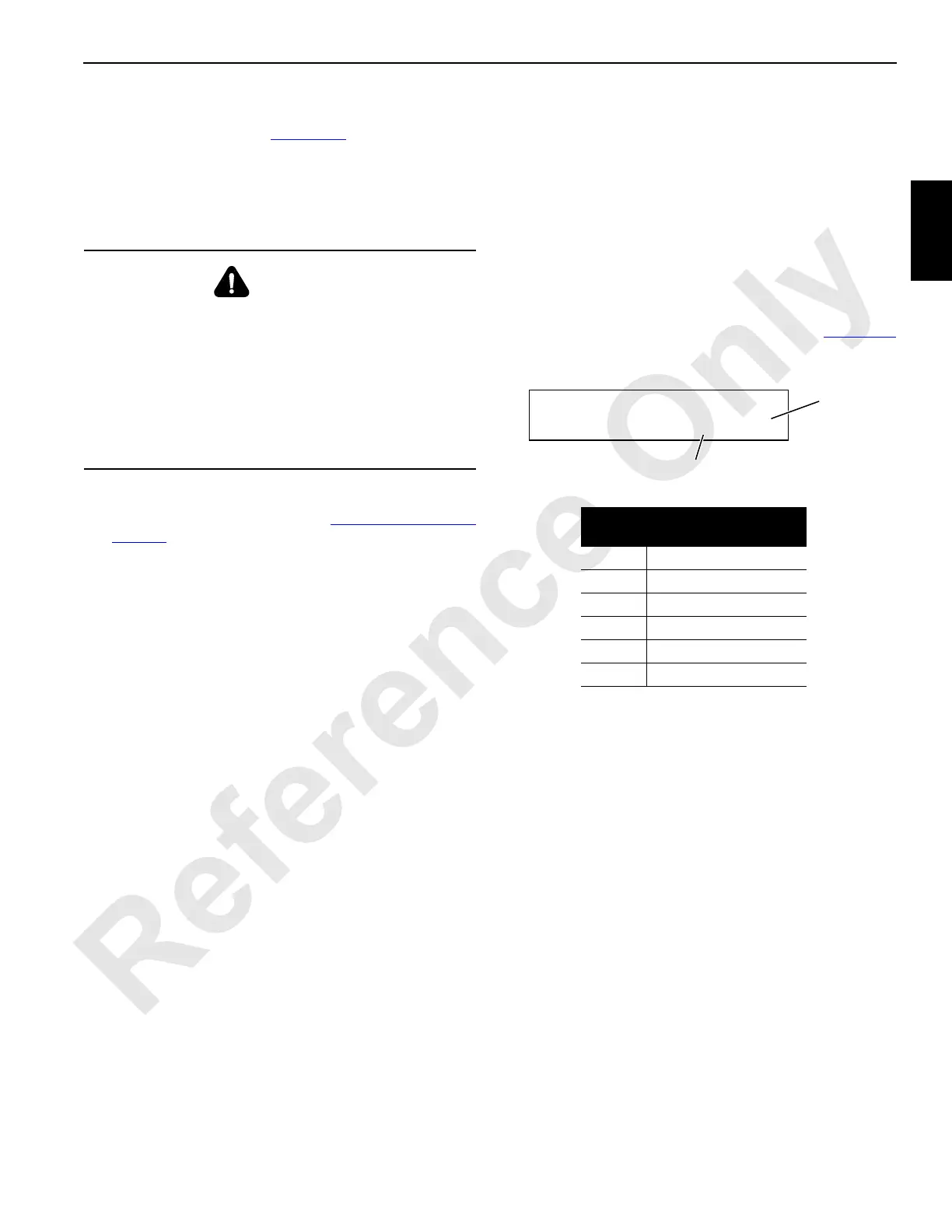

5. Check binary number in screen when calibration is

done:

a. If 0 appears, all items have passed.

b. If any number other then 0 appears, use Table 2-10.

to determine which items have failed.

WARNING

High Pressure Hazard!

This test generates maximum pressure in the main

hydraulic circuits. Defective brakes may allow unintended

motion during test. Move the crane to an area where such

motion is not a hazard.

Use a signal person to monitor functions operator cannot

see.

Be prepared to stop engine if unintended motion occurs.

HYD SYSTEM CHECK

* PUMP PRES 0% 15

FIGURE 2-12

Binary

Number

Percent

Complete

Binary

Number

Calibration Item

1 Front Drum

2 Rear Drum

4 Boom Hoist

8 Auxiliary Drum

16 Travel Right

32 Travel Left

Loading...

Loading...