HOIST AND COUNTERWEIGHT RT540E SERVICE MANUAL

5-6 Published 4-20-2015, Control # 502-01

more dangerous failure. Early detection of accelerated

component wear allows the scheduling of corrective

maintenance.

Prepare the hoist by cleaning the drain plug area and drain

extension tube in order to obtain an uncontaminated

sample. Operate the hoist in both directions for one or two

minutes to thoroughly mix the gear oil then take the sample

from the midstream flow of the oil to obtain an accurate

representation of the oil condition. After taking the oil sample

continue with the oil change or refill the hoist gear cavity to

the proper level with recommended lubricant. Iron

contaminant levels will be on the high side of “normal”

during initial break-in.

Equally important as the level of contamination is the

change in level of contamination. An effective oil analysis

program should provide the technician with a view of the

progression of wear or a trend. If a sample shows a sudden

rise in contaminant level action should be taken to

determine what has changed.

NOTE: Oil analysis alone cannot detect nor warn against a

fatigue failure.

BRAKE TEST PROCEDURE FOR HP15C-

17G, HO30A-19G, HP35-26G HOISTS

All of the above model planetary hoists have a spring

applied, hydraulically released, multiple disc brake inside

the hoist housing. This brake holds a suspended load when

the directional control valve is in neutral, or when hydraulic

power is lost. An over-running brake clutch assembly

permits the power train and drum to rotate in the direction to

lift a load, while the brake remains fully applied. A load

cannot be lowered, however, without applying hydraulic

pressure to the release port and releasing the brake.

Brake Test Procedure (To be performed with

no load on the hoist)

• Remove and cap or plug the brake release line from

fitting in the hoist brake release port.

• With the hydraulic power unit running, move the

directional control valve handle slowly to the full open,

lowering position.

• Increase the engine speed, if necessary, to bring system

pressure up to the relief valve setting. The hoist drum

should remain stationary

• If the hoist drum rotates, the hoist should be

disassembled and the brake components should be

examined for wear. In addition, the brake springs should

be measured for the correct free length in those hoist

using helical compression springs.

• Replace any parts showing excessive wear and any

spring whose length is shorter than the minimum shown

in the applicable hoist Service Manual.

• Reassemble the brake and hoist, then repeat the above

steps.

• When testing is complete, reattach the brake release

line to the brake release port.

Contact CraneCARE with any questions

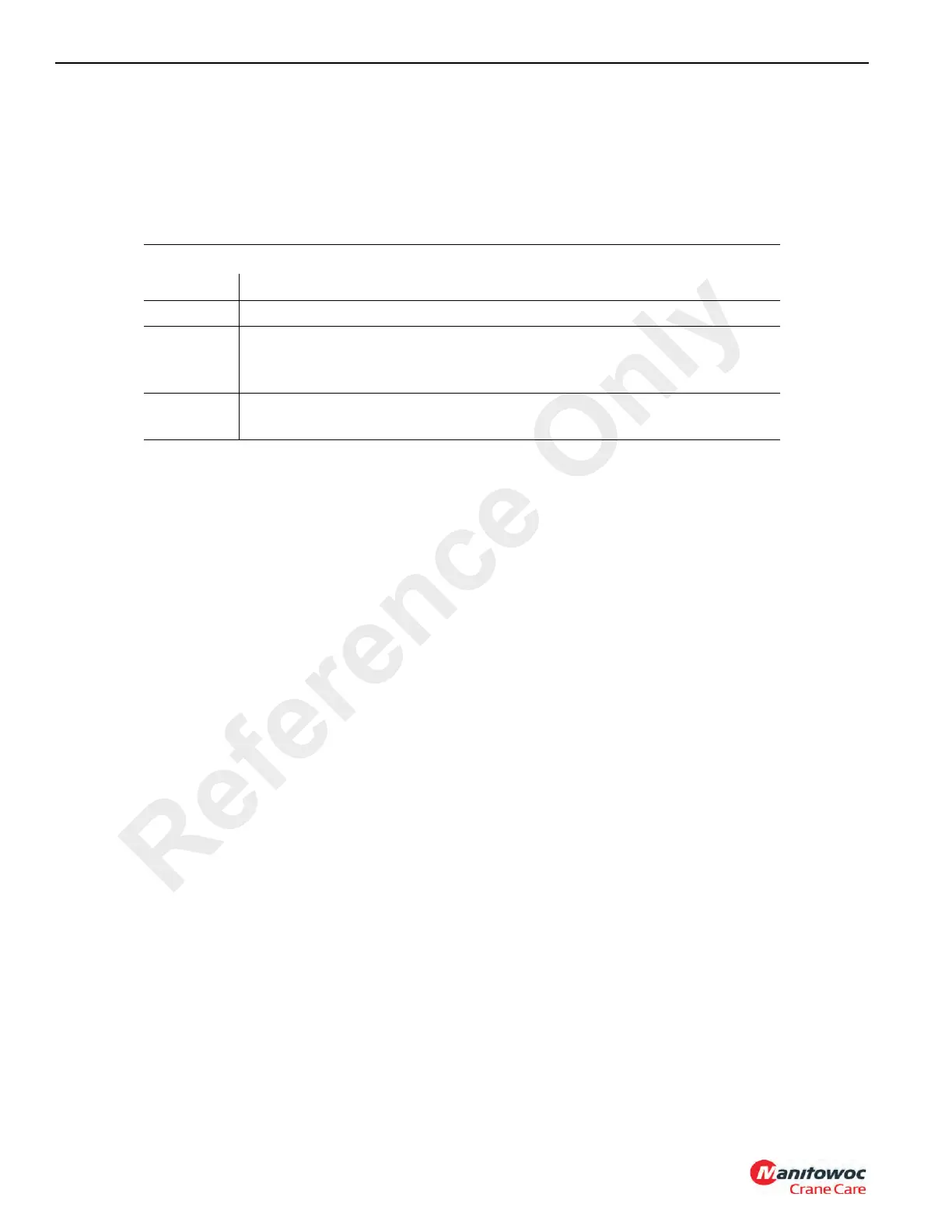

General guidelines for iron contaminant level

PPM Condition of Oil

100-500 Normal - Acceptable level; little significant contamination

500-800

Caution - Abnormal sample. Change oil and retake sample after 50 hours of

operation. If second sample is above 500 ppm, remove hoist from service and

perform tear-down inspection to determine source of contamination.

Over 800

Unacceptable - Remove hoist from service and perform tear-down inspection to

determine the source of contamination.

Reference Only

Loading...

Loading...