UNDERCARRIAGE RT540E SERVICE MANUAL

8-22 Published 4-20-2015, Control # 502-01

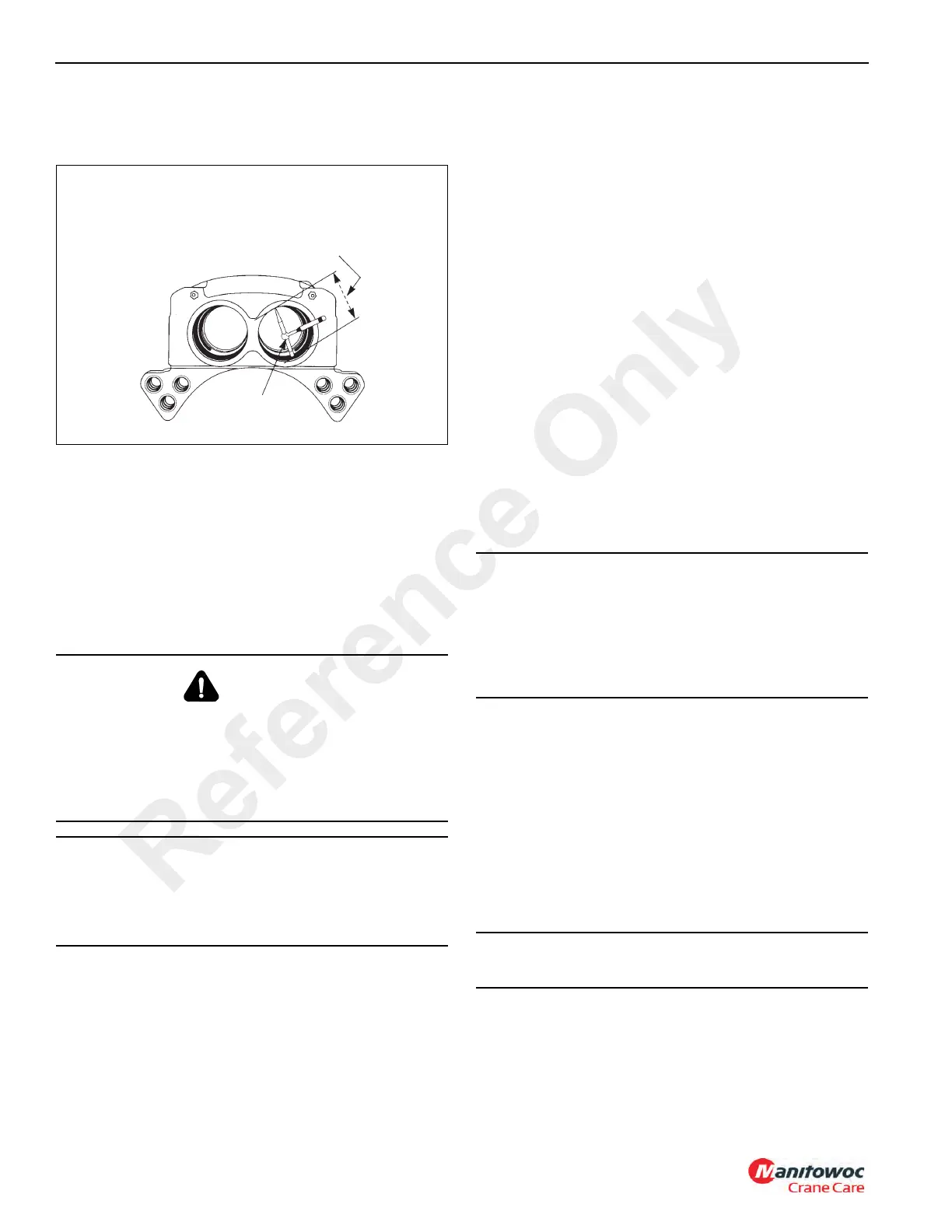

3. Measure the diameter of the housing bore. Replace the

housing if the diameter is worn to more than 76.276 mm

(3.003 in) (Figure 8-23).

4. Inspect the linings as described previously.

5. Inspect the threads of the caliper, cylinder caps, and all

fittings. Replace any component that has thread

damage that cannot be repaired.

6. Discard all back-up rings, o-rings, and dust seals. Use

new ones when assembling the caliper.

Cleaning

• Use solvent cleaners to clean all metal parts that

have ground or polished surfaces. Examples of

ground or polished parts are the piston and the

piston bore in the caliper.

• Metal parts with rough surfaces can be cleaned with

solvent cleaners or with alkaline solutions.

• Use a wire brush to clean the threads of fasteners

and fittings.

• Use soap and water to clean parts that are not made

of metal.

• Scrape away build-ups of mud and dirt on the

linings. Replace all linings contaminated with oil or

grease.

• Immediately after cleaning, dry all parts with clean

paper or rags.

Corrosion Protection

Apply brake system fluid to the cleaned and dried parts that

are not damaged and are to be immediately assembled. Do

Not apply fluid to the brake linings or the disc.

If parts are to be stored, apply a special material that

prevents corrosion to all surfaces. Do Not apply the material

to the brake linings or the disc. Store the parts inside special

paper or other material that prevents corrosion.

Assembly

Caliper

NOTE: The o-rings, back-up rings, pistons, and bores

must be lubricated before installing the pistons.

1. Lubricate all pistons, bores, o-rings, and back-up rings

with silicone grease. If silicone grease is not available,

use the same type of fluid that is used in the brake

system.

2. Install new o-ring and a new back-up ring in the groove

in the middle of the bore. The o-ring is installed toward

the outboard end of the bore. The back-up ring is

installed toward the lining side of the bore (Figure 8-16).

3. Install a new dust seal in the top groove of the bore

(Figure 8-24).

DANGER

Use of cleaning solvents, hot solution tanks, or alkaline

solutions incorrectly, can cause serious personal injury. To

prevent serious personal injury, follow the instructions

supplied by the manufacturer of these products. Do not

use gasoline to clean parts. Gasoline can explode and

cause serious personal injury.

CAUTION

Use only solvent cleaners to clean ground or polished

metal parts. Hot solution tanks or water and alkaline

solutions will damage these Parts. Isopropyl alcohol,

kerosene, or diesel fuel can be used for this purpose.

Telescoping

Gauge

Replace Housing if Bore

is Worn to More than

76.276 mm (3.003 in)

FIGURE 8-23

CAUTION

Use only specified components when assembling the

calipers. Do not mix components from other calipers.

Installing the wrong components may cause the caliper

not to operate correctly and may cause damage to

equipment. Use of non manufacturer’s parts can cause

damage, loss of braking, and serious personal injury.

CAUTION

Do not use silicone grease on the dust seal.

Reference Only

Loading...

Loading...