Published 4-20-2015, Control # 502-01 2-33

RT540E SERVICE MANUAL HYDRAULIC SYSTEM

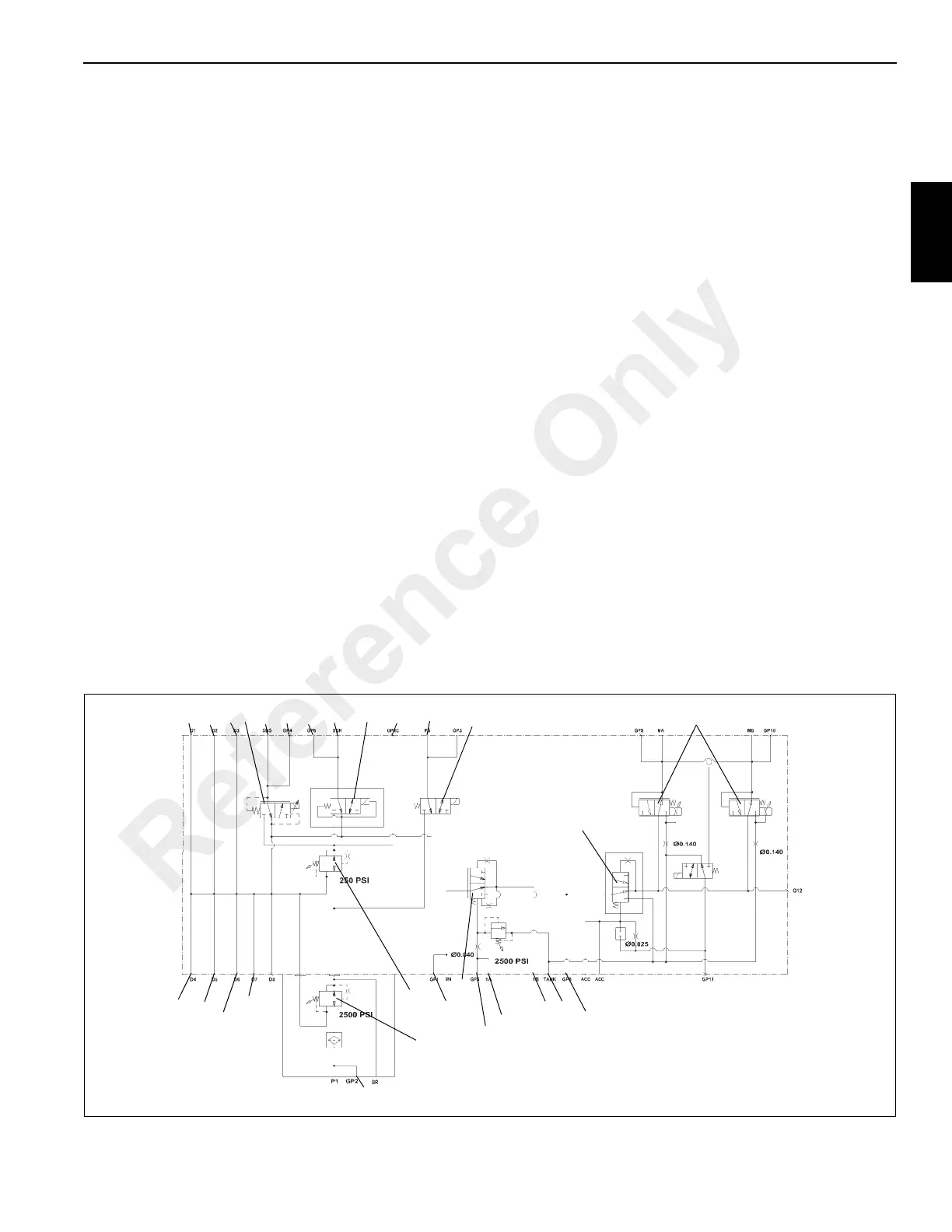

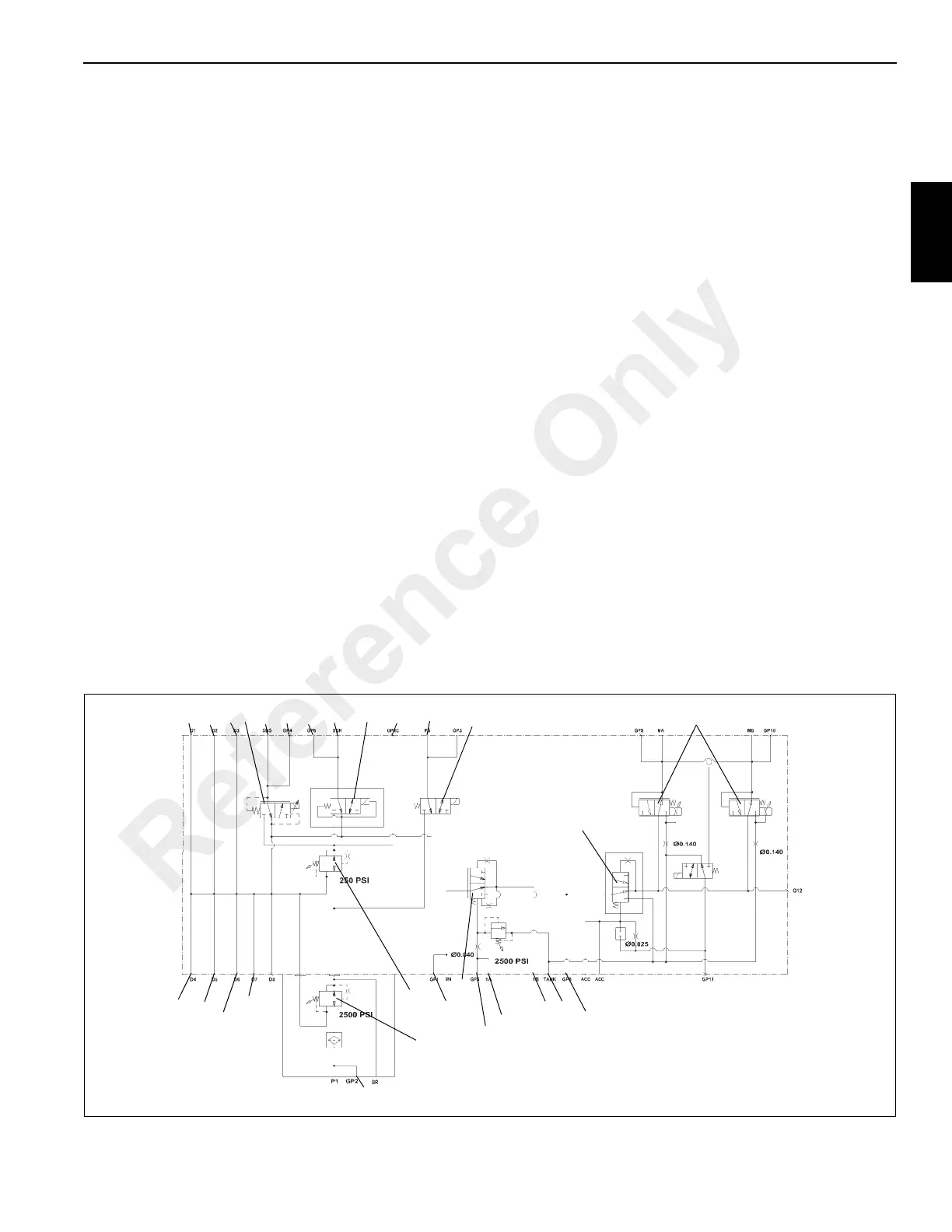

ACCESSORY WITH SWING DIRECTIONAL

CONTROL MANIFOLD

Description

The accessory manifold with swing directional valve

(Figure 2-16) is located on the right side of the turntable. The

manifold contains two adjustable pressure reducing valves,

five 3-way two position solenoid valves, a 3-way four position

swing directional valve, and a check valve.

One pressure reducing valve provides 1.72 MPa (250 psi) for

operation of the swing brake. The other provides 17.2 MPa

(2500 psi) for the pilot circuit.

Each solenoid valve is held in its normally closed position by

a spring. When the solenoid is energized, the plunger

assembly forces the spool to shift, causing the valve to shift.

De-energizing the solenoid causes spring pressure to shift

the spool to its normally closed position.

One two position, three way solenoid valve serves as the

swing brake release valve. This normally closed valve, when

de-energized, prevents hydraulic oil pressure from releasing

the swing brake. When the swing brake switch is off, this

valve opens to allow hydraulic oil pressure to release the

swing brake.

One proportional two position, three way solenoid valve

actuated by the cab swing foot brake proportionally supplies

pressurized oil to the swing drive brake.

The three position four-way swing directional valve is

installed onto the manifold. Both swing working ports have

check valves that are flooded by a.41 MPa (60 psi)

resistance check valve providing make-up oil to the swing

motor for motor over-run when the valve is centered. It

receives oil from pump #1 through swivel port 5. This section

is controlled by two proportional two position, three way

solenoid valves. These valves receive an electrical signal

from the cab armrest controllers.

Maintenance

Removal

1. Tag and disconnect all of the electrical connectors or

manual control levers.

2. Tag and disconnect the hydraulic lines from the valves.

Cap or plug the lines and ports.

NOTE: The swing/steer/brake valve manifold weighs

approximately 10.0 kg (22.0 lb).

3. Remove the capscrews, lockwashers and flatwashers

securing the manifold. Remove the manifold.

Installation

1. Place the manifold on the superstructure side plate and

secure with the capscrews, lockwashers and

flatwashers. Torque the capscrews see Fasteners and

Torque Values, page 1-11.

2. Connect the hydraulic lines to the valves as tagged

during removal.

3. Connect the electrical connectors to the valve as tagged

during removal.

19

4

25

20

3

9

23 2

5

8

6

16

21

10

13

22

14

15

7

1

17

18

12

11

24

26

27

28

8462

FIGURE 2-16

Reference Only

Loading...

Loading...