Grove Published 11-22-2016, Control # 345-12 6-15

RT9130E-2 SERVICE MANUAL SWING SYSTEM

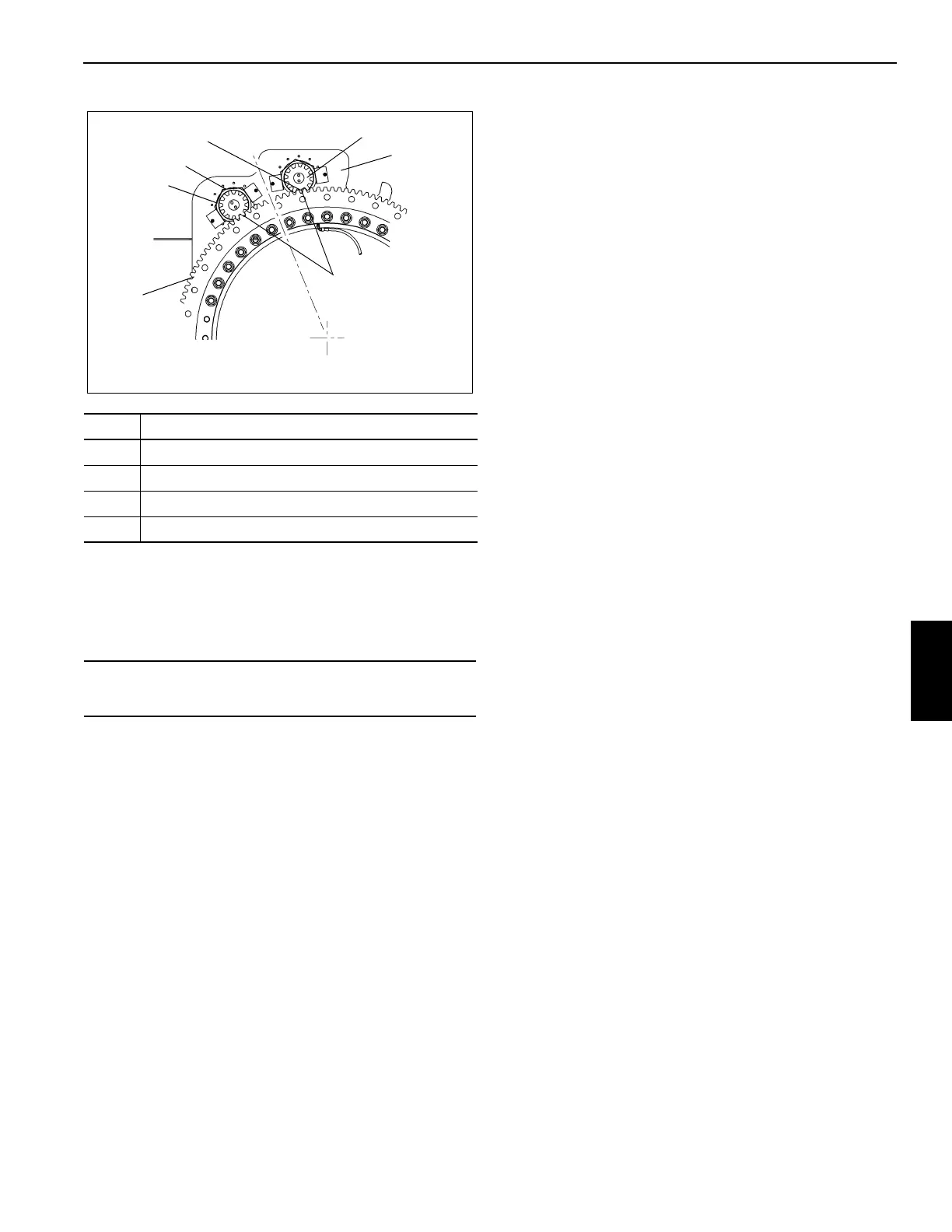

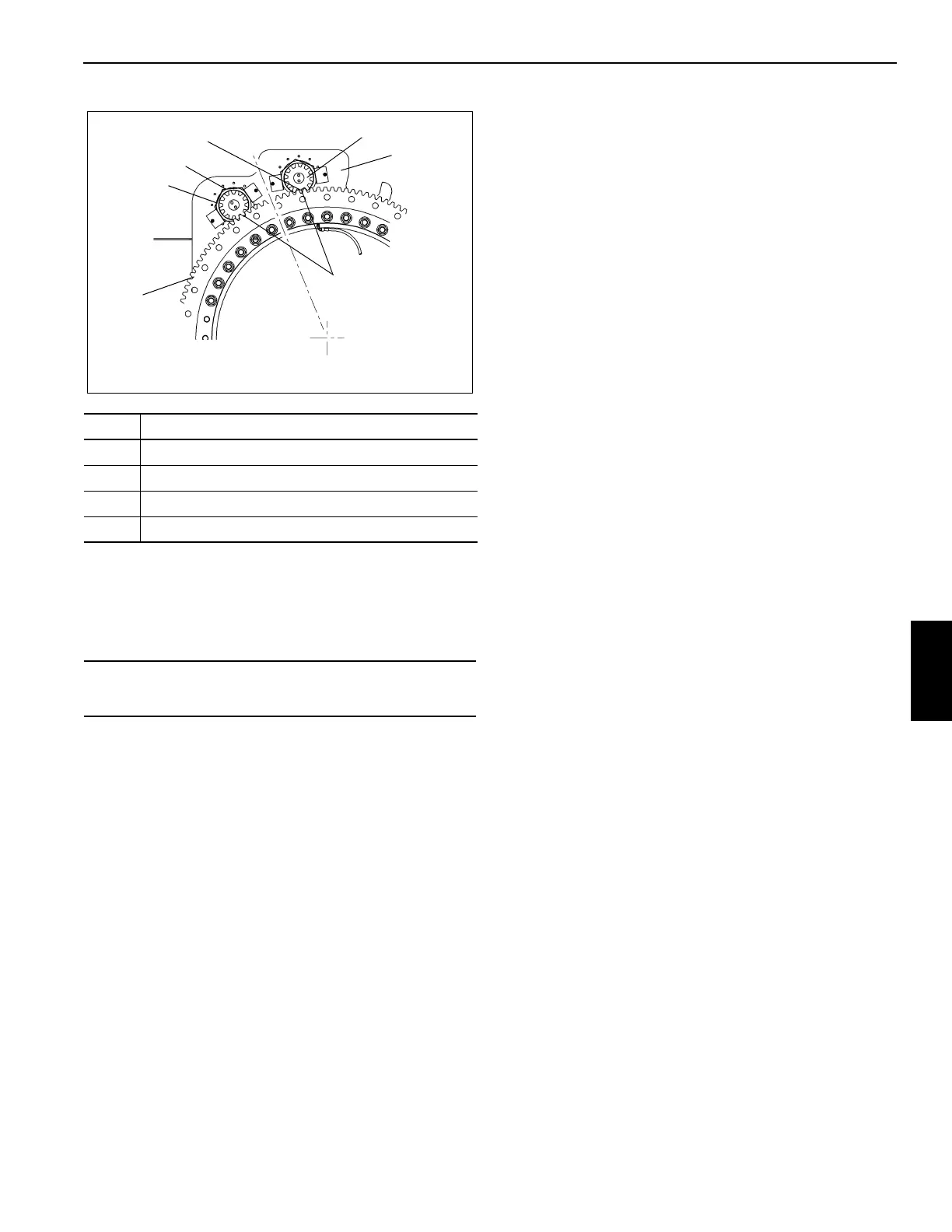

5. Orient ring gear such that its point of max eccentricity

(“high point”) is located between the swing drives.

Position swing drives so that pinion is centered within

cutout in base plate and motor ports face towards the

outboard side (Figure 6-4).

a. Using shims, set backlash by moving the swing

drive assemblies toward the bearing in order to

mesh the pinion with the ring gear teeth.

b. Check tooth engagement squareness and vertical

tooth engagement.

c. Remove backlash shims and recheck backlash.

6. Position the two retainer plates on the bottom of

hydraulic swivel spool, engaging the lugs on the carrier

frame, and secure them to the spool with four bolt

retainers and eight bolts. Bend all the retainer tabs to

make contact with the bolt heads.

7. Plug the swivel wiring harness connectors into the

carrier receptacles. Secure the ground wire to the

ground stud using a washer, lockwasher, and nut.

8. Install the clamp securing the swivel wiring harness to

the retainer plate on the bottom of the hydraulic swivel.

9. Connect all water and hydraulic lines to the ports on the

bottom of the swivel as tagged during removal.

10. Install the boom and lift cylinder following the procedures

outlined in Boom, page 4-1.

11. Install the counterweight and auxiliary hoist following

procedures outlined in Hoist and Counterweight, page 5-

1.

12. Reconnect the batteries.

13. Check the slew potentiometer in the electrical swivel for

proper orientation. Refer to Swivels, page 6-16.

Testing

Activate the crane and check for proper function.

NOTE: If the superstructure does not turn freely after

bearing and pinion replacement, contact your local

distributor.

Item Description

1 Bearing

2 Swing Gearbox

3 Pinion Guard

4 Turntable

CAUTION

Do not clamp over pinion.

FIGURE 6-4

Tooth Identified As Max Eccentricity

.005 Thick Shim By Full

Widt h To To o t h

Engagement (0.010

Backlash) 2 Places

6686

4

2

3

2

1

Loading...

Loading...