OM 780-2 Page 47

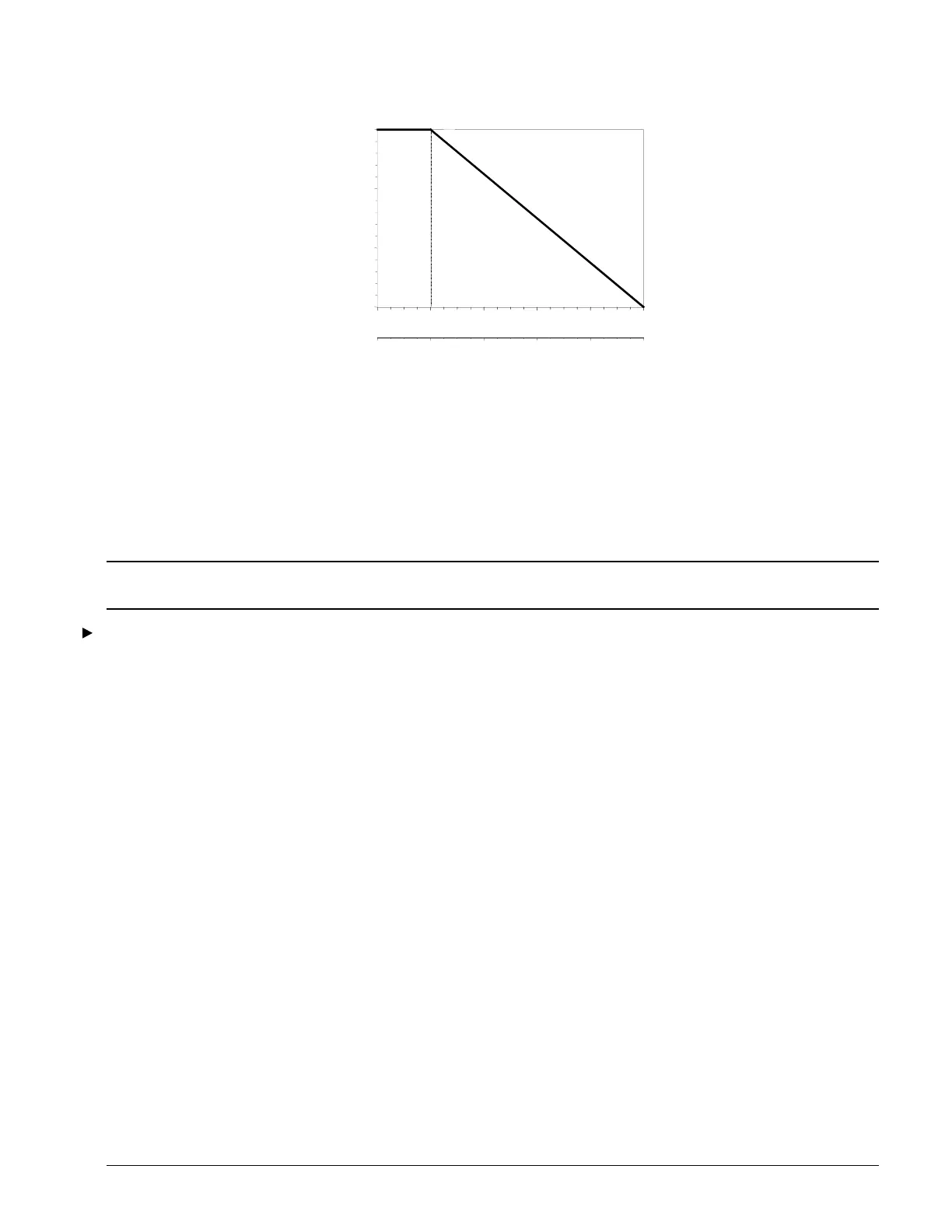

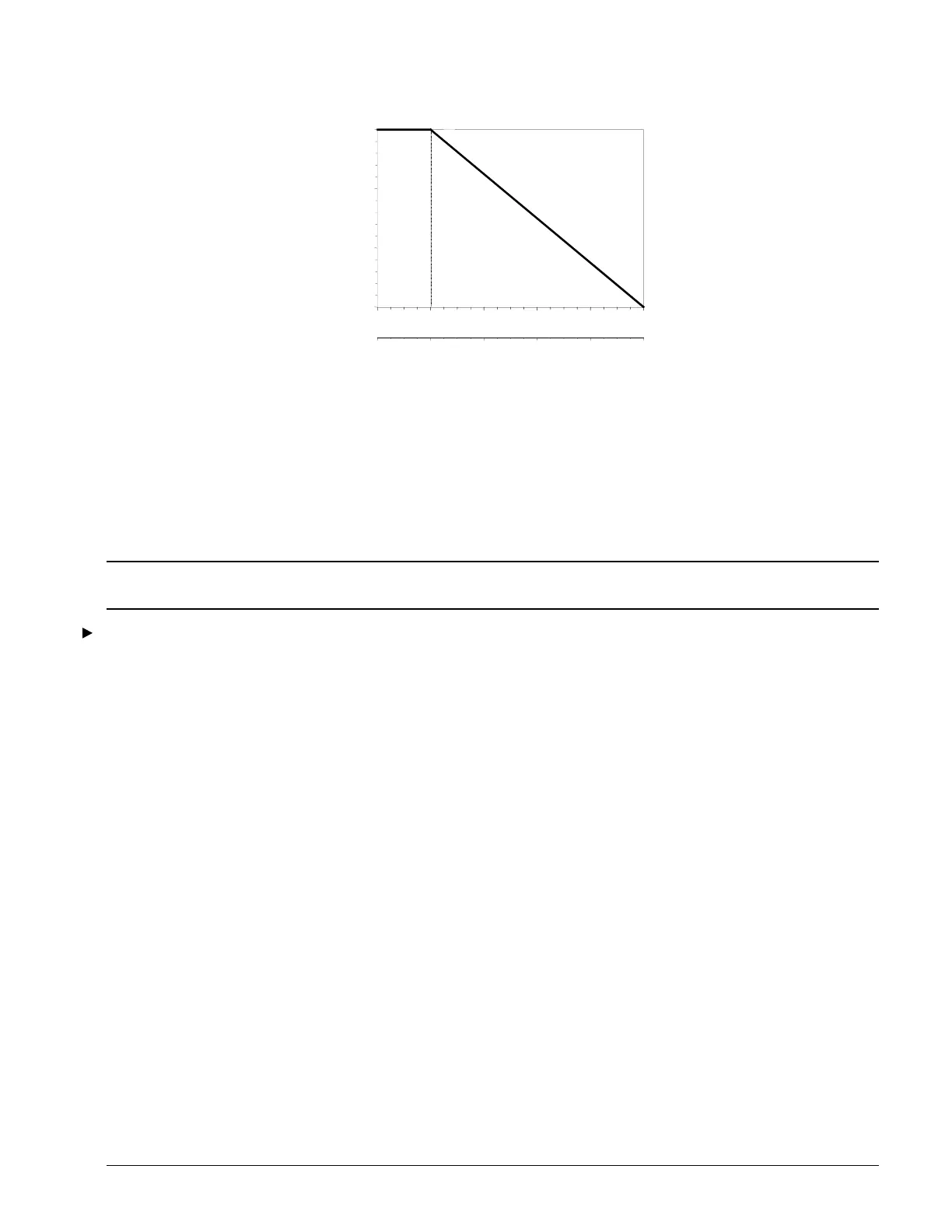

Figure 15. External Signal Demand Limiting Function

40

60

80

100

Capacity Limit (% Load)

0246 108

04812 2016

External Signal

0–10 Vdc:

0–20 mA:

Demand Limiting via Network Signal

If the Demand Limiting Type variable is set to “BACnet” or “Modbus”, the CSM accepts a capacity limit value sent by a

BAS. The value from the BAS becomes the System Demand Limiting Load Limit; however, the CSM limits the value to a

range of 40% to 100%. For example, if the BAS writes a value of 20%, the System Demand Limiting Load Limit variable

is set to 40%.

Note: If communications are lost with a BAS that is supplying the demand limiting value, the CSM retains and uses the

last value it received. To override, set the Demand Limiting Type to “None” on the Load Limiting screen.

To set up demand limiting control

1. Set the Demand Limiting Type variable as required. If you do not want demand limiting control, set it to “None.”

Load Balancing

The CSM will provide load-balancing control for all chillers assigned to a Load Balancing Group #. Centrifugal, screw

and scroll chiller types should not be balanced together due to the their means of capacity increase. For example a

centrifugal chiller which ramps its capacity linearly cannot be properly balanced with a scroll compressor which increases

its capacity in large increments (e.g. 25%).

Centrifugal chillers are typically the only chillers that are load balanced. If you intend to load balance screw or scroll

chiller types you must increase the Load Balancing Capacity Difference Limit to be greater than the capacity increase

increment of the chillers being balanced.

If load balancing flag = YES, the capacity limit of all chillers with the same Load Balancing Group Number will be

affected.

When to Use Load Balancing

Load balancing control is optional. Load balancing is often used (but not required) when there is at least one set of series-

piped chillers in the system. When load balancing is used for series-piped chillers, both chillers of the series-piped pair are

typically balanced together (i.e. chillers 1 and 2 have Load Balancing Group Number = 1, chillers 3 and 4 have Load

Balancing Group Number = 2, etc).

If all the chillers are piped in parallel, as long as their leaving evaporator water temperature setpoints are the same, chillers

in these systems tend to automatically balance their loads as they control their chilled water temperatures. In fact, load-

balancing control can actually override chilled water temperature control. So if load-balancing control is in use, you can

expect some variation in the chillers’ leaving evaporator water temperatures. This is more likely to occur in a system that

has chillers with a wide range of efficiencies. When load balancing is used for parallel-piped chillers, all centrifugal

chillers in the system are typically balanced together (i.e. all chillers have a Load Balancing Group Number = 1).

Loading...

Loading...