OM 780-2 Page 67

• Tower Valve Propband

• Tower Valve Sample Time

• Tower Valve Integral Time

• Minimum Tower Valve Start-Up Position

• Maximum Tower Valve Start-Up Position

• Minimum Tower Valve Start-Up Position At (OAT)

• Maximum Tower Valve Start-Up Position At (OAT)

Chilled Water Flow Control

The CSM can maintain a constant differential pressure across the cooling loads by controlling a loop bypass valve, variable

speed cooling load pump(s), or a set of constant speed cooling load pumps. For applications that require a “lead/standby”

arrangement of two pumps, the CSM can automatically alternate the lead pump to equalize run time. To view the current

values of the load flow operation, go to the Flow screen. To configure the chilled water flow control operation, go to the

Load Flow Control screen to change the values described in Table 16.

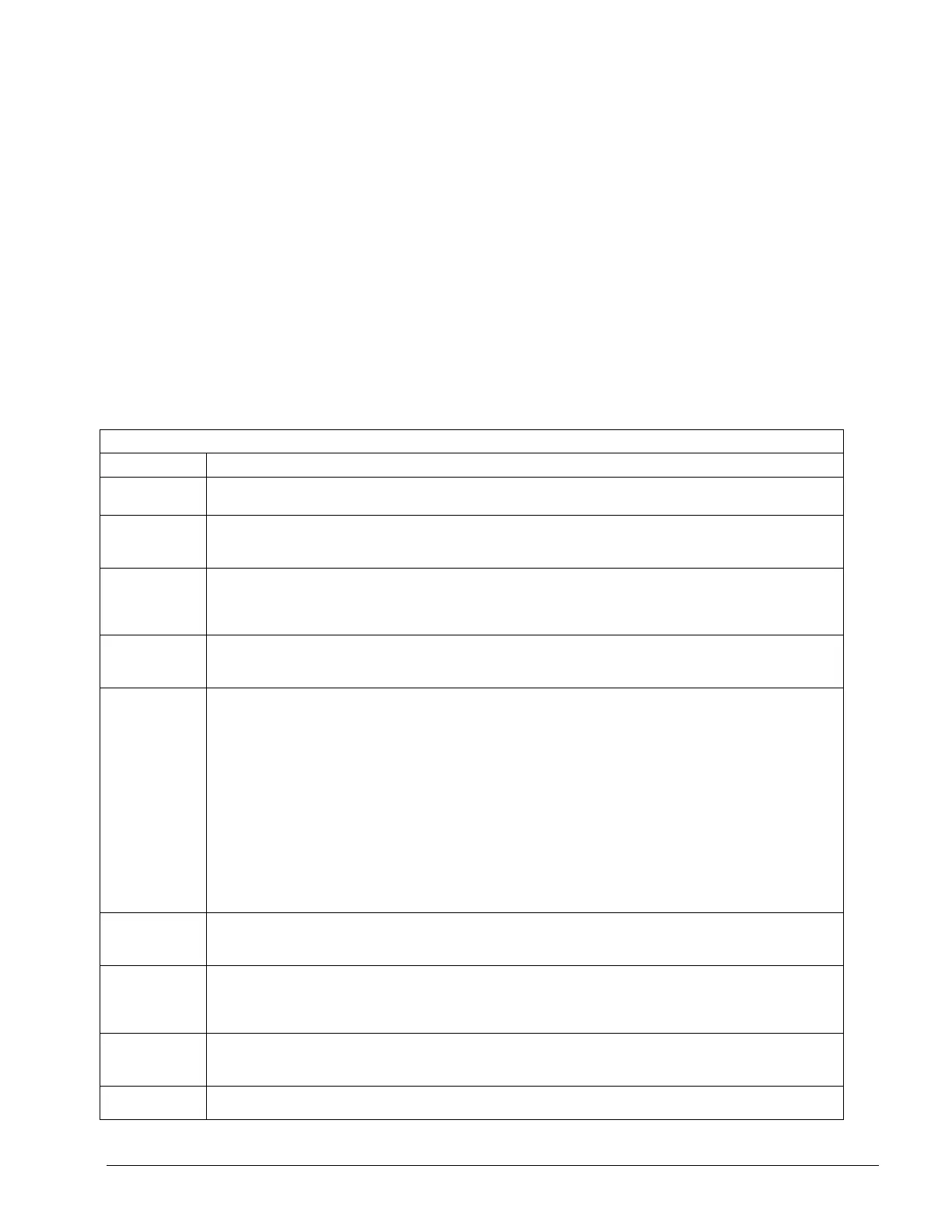

Table 16. Load Flow Control (Main > Configuration > Load Flow Control)

Load Flow Control

Name Description

Pump Control

Option

If the CSM will be controlling cooling load pumping, set this value to meet the pump configuration. Range = None, One

Pump, Auto Lead, Pump 1 Lead, Pump 2 Lead, Sequencing, Multiple VFD Pumps. Default = None

Pump Status

Check Delay

Time

Used to determine a pumps alarm status. Any time the CSM has enabled a pump it monitors that pumps status switch. If

the status switch of an enabled pump is open, the CSM waits until this Pump Status Check Delay time expires before

setting the pump in alarm. Range = 1 to 60 seconds. Default = 30 seconds

Lead/Standby

Pump

Resequence

Day/Time

If the Pump Control Option is Auto Lead (or Pump 1 Lead or Pump 2 Lead and you have manually switched from one to

the other) this variable will force the running pump to be replaced by a new lead pump at a defined time. A requirement is

that the lead pump has changed to the non-operating pump during the continuous run period of the running pump. Default

= N/A

Resequence

Lead/Standby

Pumps NOW

If the Pump Control Option is Auto Lead (or Pump 1 Lead or Pump 2 Lead and you have manually switched from one to

the other) this button will force the running pump to be replaced by a new lead pump immediately. A requirement is that

the lead pump has changed to the non-operating pump during the continuous run period of the running pump.

Pump 1 Runtime

Reset

Pump 2 Runtime

Reset

Pump 3 Runtime

Reset

Pump 4 Runtime

Reset

Pump 5 Runtime

Reset

Pump 6 Runtime

Reset

The Pump Runtime Reset variables can be used to tell the CSM what the pump runtime value is for an existing pump.

Also, if an old pump is replace by a new pump, the runtime can be reset to zero. The CSM uses pump runtime to determine

a “lead” pump when Pump Control Option = Auto Lead. It also uses pump runtime to determine the next pump to enable

when Pump Control Option = Multiple VFD Pumps

Chilled Water

Loop Modulation

Control Option

If the CSM will be controlling the differential pressure across the load, set this value to meet the system configuration.

Range = None, Chilled Water Loop Bypass Valve, Pump VFD. Default = None

Loop Differential

Pressure Setpoint

This input is the user defined differential pressure across the load setpoint. If the Chilled Water Loop Modulation Control

Option = Chilled Water Loop Bypass Valve or Pump VFD, the output will be modulated to maintain the differential

pressure at this setpoint. If the Pump Control Option = Sequencing, pump stages will be increased to supply this

differential pressure. Range = 2 - 99 psi (13 – 683 kPa). Default = 10 psi (69 kPa)

Loop Differential

Pressure

Deadband

This value sets a Deadband around the Loop Differential Pressure Setpoint. No control action is taken when the current

Differential Pressure is within this Deadband around the Loop Differential Pressure Setpoint. Range = 0 – 9 psi (0 – 62

kPa). Default = 2 psi (13 kPa)

Loop Differential

Pressure

This value sets the “proportional band” used in the PID control function that modulates the loop differential pressure. In

general, increasing this value has a slowing effect and decreasing this value has a speeding effect on the control of the valve

Loading...

Loading...