14. COMMUNICATION FUNCTION

14 - 28

14.5.6 Disabling/enabling I/O devices (DIO)

You can disable inputs regardless of the I/O device status. When inputs are disabled, the input signals

(devices) are recognized as follows. However, EM2 (Forced stop 2), LSP (Forward rotation stroke end), and

LSN (Reverse rotation stroke end) cannot be disabled.

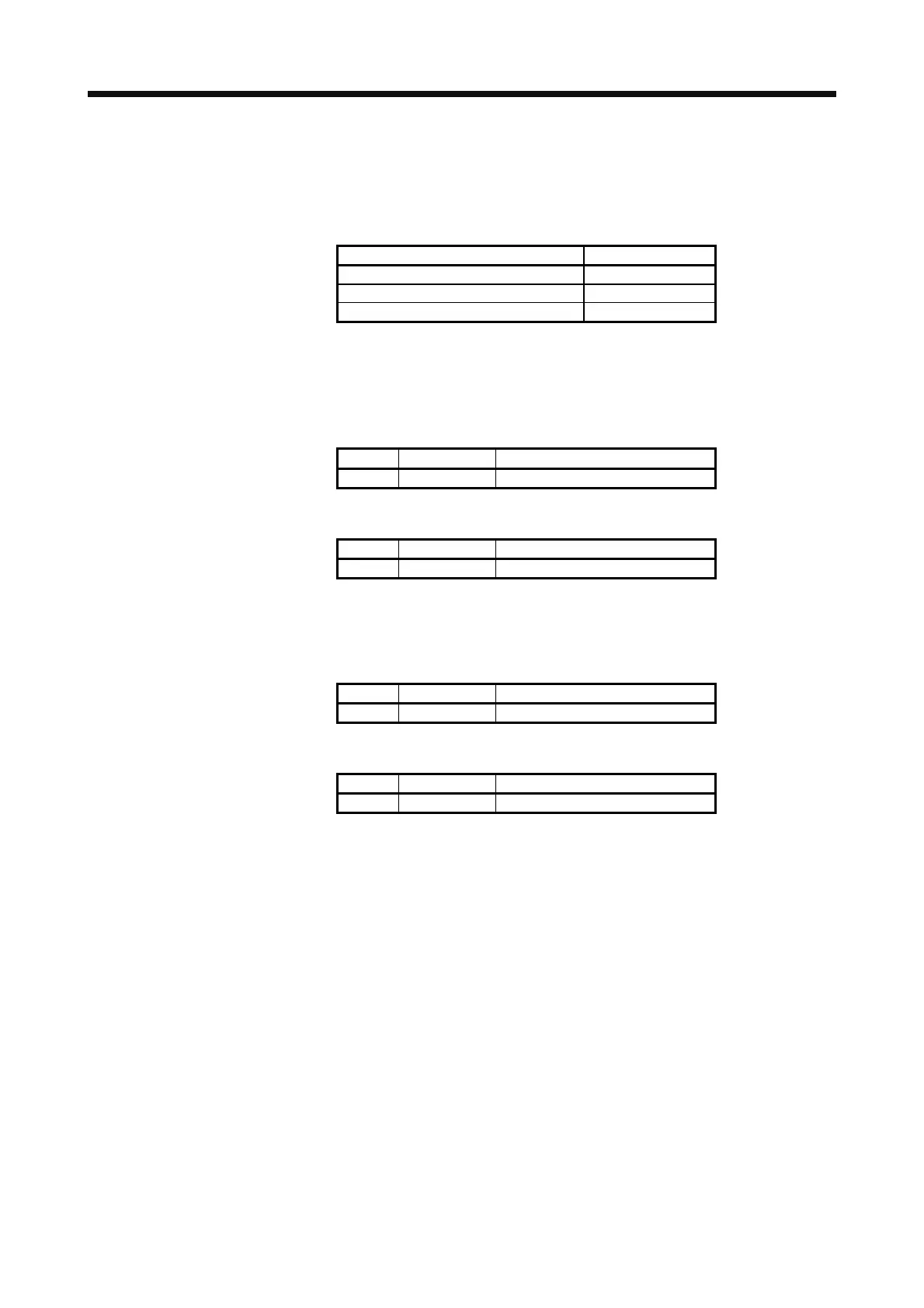

Signal Status

Input device (DI) Off

External analog input signal 0 V

Pulse train input None

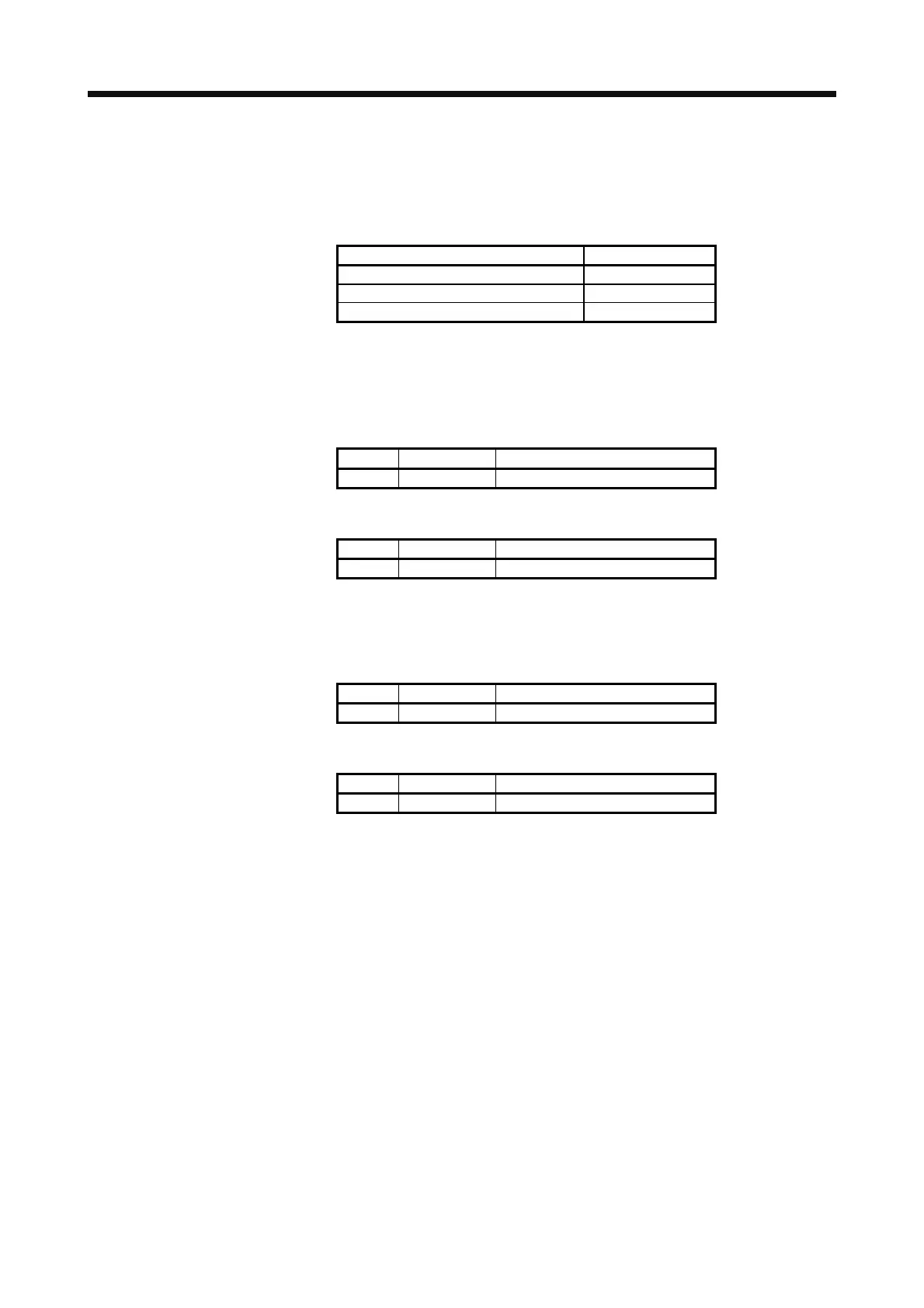

(1) Disabling/enabling the input devices (DI), external analog input signals and pulse train inputs except

EM2 (Forced stop 2), LSP (Forward rotation stroke end), and LSN (Reverse rotation stroke end).

Transmit the following communication commands.

(a) Disabling

Command Data No. Data

[9] [0] [0] [0] 1EA5

(b) Enabling

Command Data No. Data

[9] [0] [1] [0] 1EA5

(2) Disabling/enabling the output devices (DO)

Transmit the following communication commands.

(a) Disabling

Command Data No. Data

[9] [0] [0] [3] 1EA5

(b) Enabling

Command Data No. Data

[9] [0] [1] [3] 1EA5

Loading...

Loading...