76 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

ENGLISH

CYLINDER BLOCK, CRANKSHAFT,

PISTONS AND OIL PAN

INSPECTION

76 / 195

Unit: mm (in.)

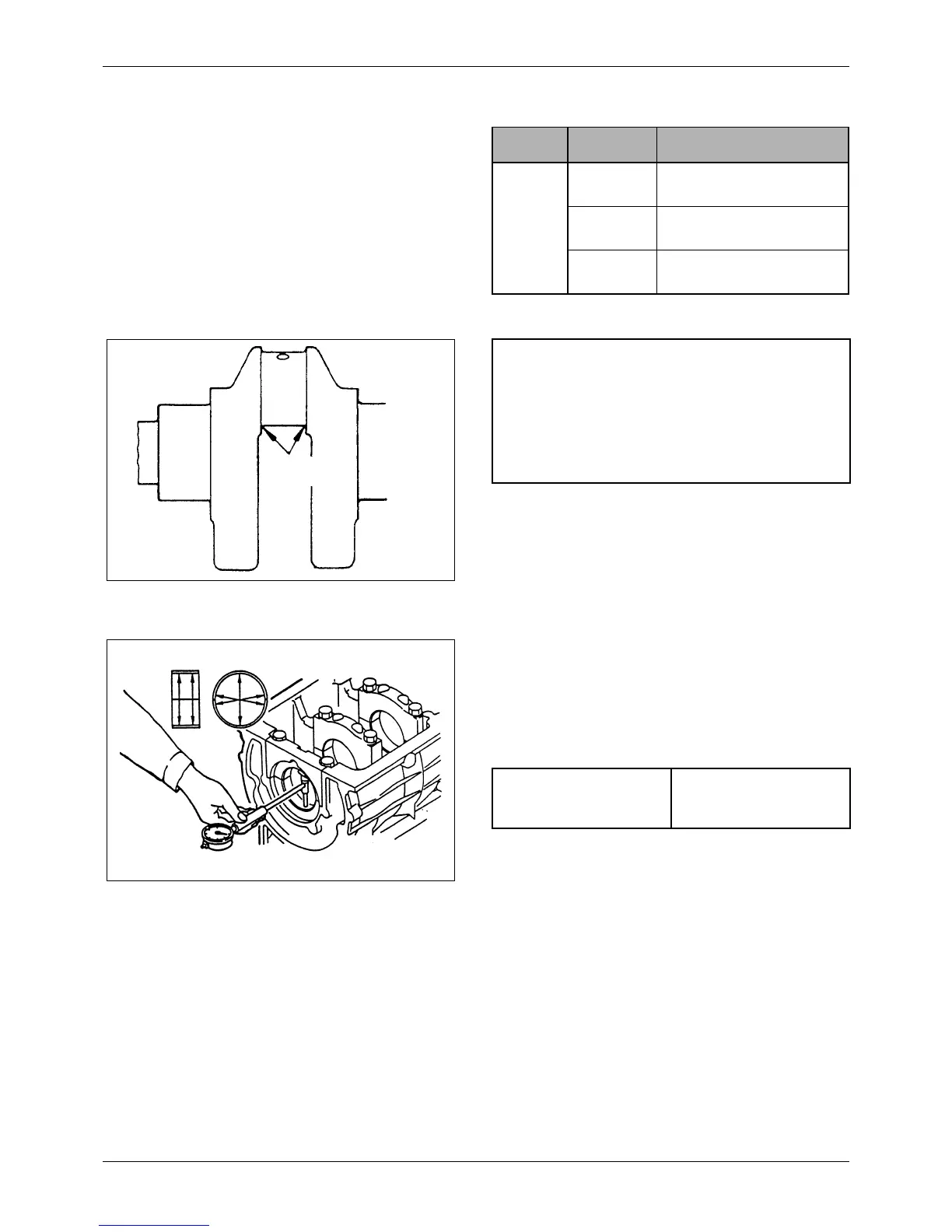

2. Clearance between journal and main bearing

1) Install the main bearing (upper and lower

halves) and cap to the cylinder block and

tighten the cap bolts to the specified torque.

Measure the bore in the bearing for the journal

as shown in the illustration.

Item Undersize Finish

Crankpin

0.25

(0.009 8)

47.75 (1.8799 )

0.50

(0.019 7)

47.50 (1.8701 )

0.75

(0.029 5)

47.25 (1.8602 )

Table 2 Crankpin undersizes

-0.035

-0.050

-0.00138

-0.00197

-0.035

-0.050

-0.00138

-0.00197

-0.035

-0.050

-0.00138

-0.00197

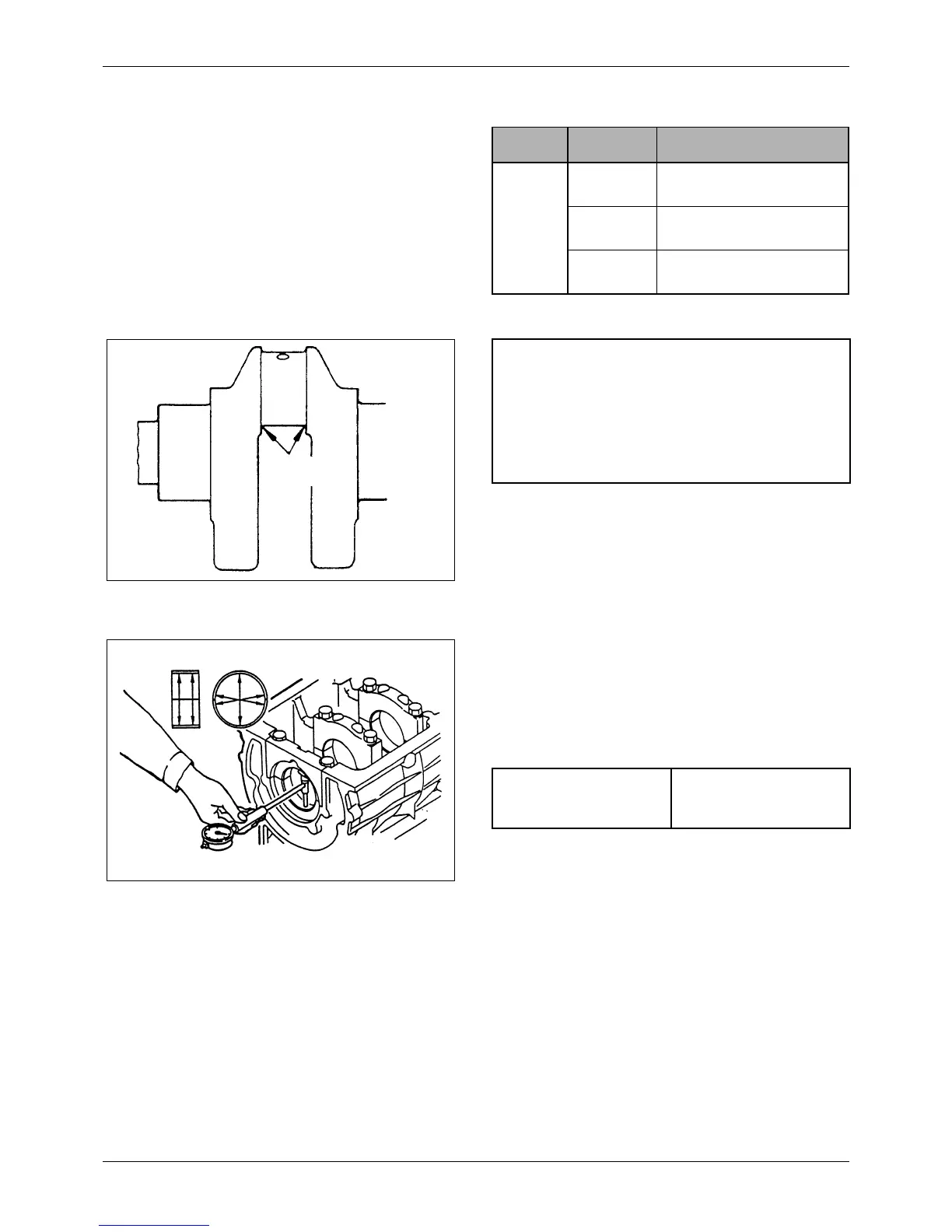

Figure 103 Crankpin fillet radius

2.5 mm

(0.098 in.)

CAUTION

• Grind all the crankpins of one crankshaft to the

same undersize.

• Finish the crankpin fillets to a radius of 2.5 mm

(0.098 in.).

Figure 104 Measuring bore in main bearing

Tightening torque

5.25 ± 0.25 kgf·m

(38 ± 1.8 lbf·ft)

[51.5 ± 2.5 N·m]

Loading...

Loading...