120 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

ENGLISH

STARTER ELECTRICAL SYSTEM

120 / 195

29.4 Inspection and Testing after

Assembly

After assembling the starter, perform the following

inspections and tests:

29.4.1 Inspection and Adjustment of

Pinion Gap

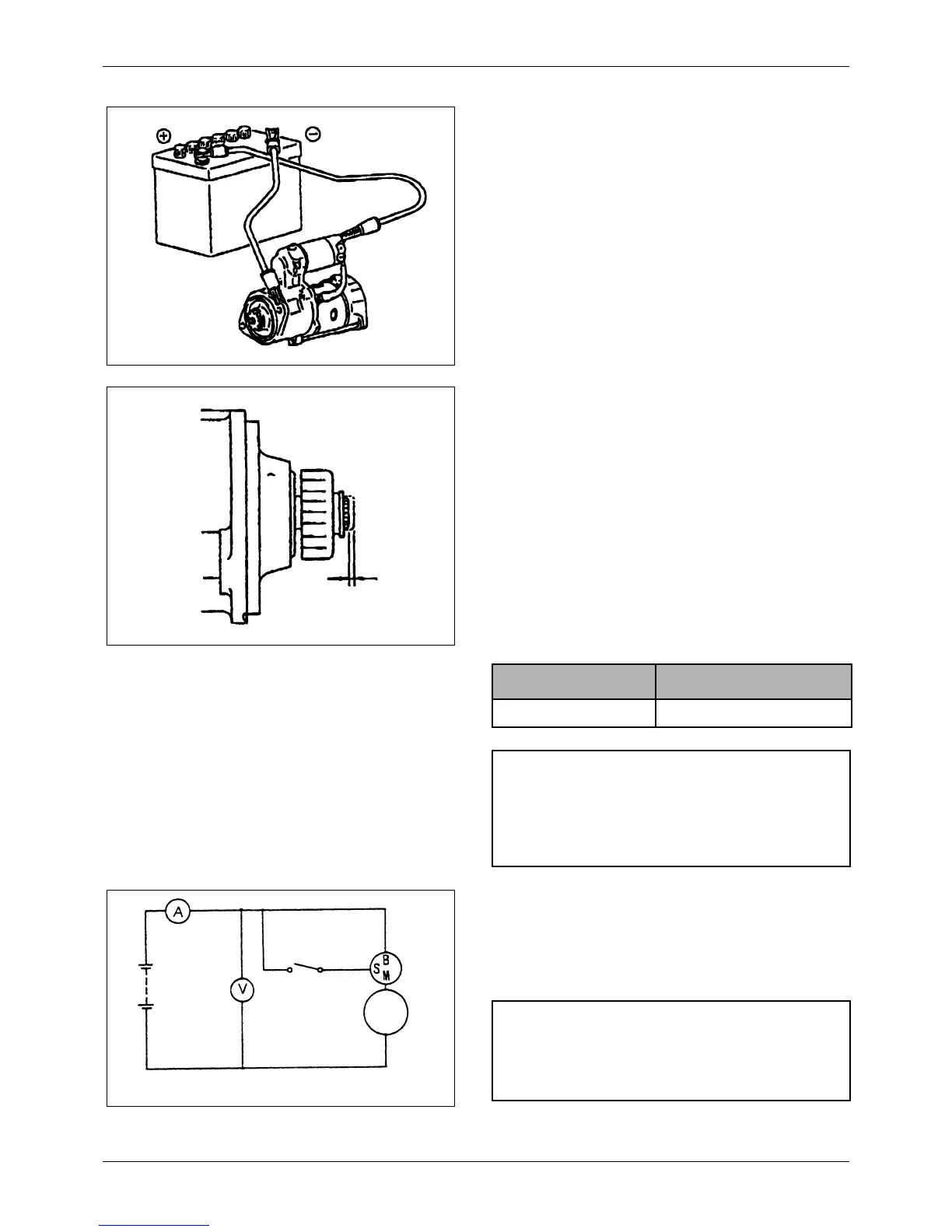

1. Connect the assembled starter to the battery as

shown in the drawing. The pinion will come out and

rotate slowly. Then, remove the M-terminal

connector to stop the motor.

2. Lightly push the pinion shaft toward the armature

and measure the amount of axial movement,

which corresponds to the pinion gap.

3. If the pinion gap is not within the 0.5 – 2.0 mm

(0.02 – 0.08 in.) range, adjust it by increasing or

decreasing the number of seals in the solenoid

switch. (Increasing the number of seals reduce the

pinion gap). It may be necessary to replace the

lever to obtain the correct pinion gap.

Unit: mm (in.)

29.4.2 No-Load Test

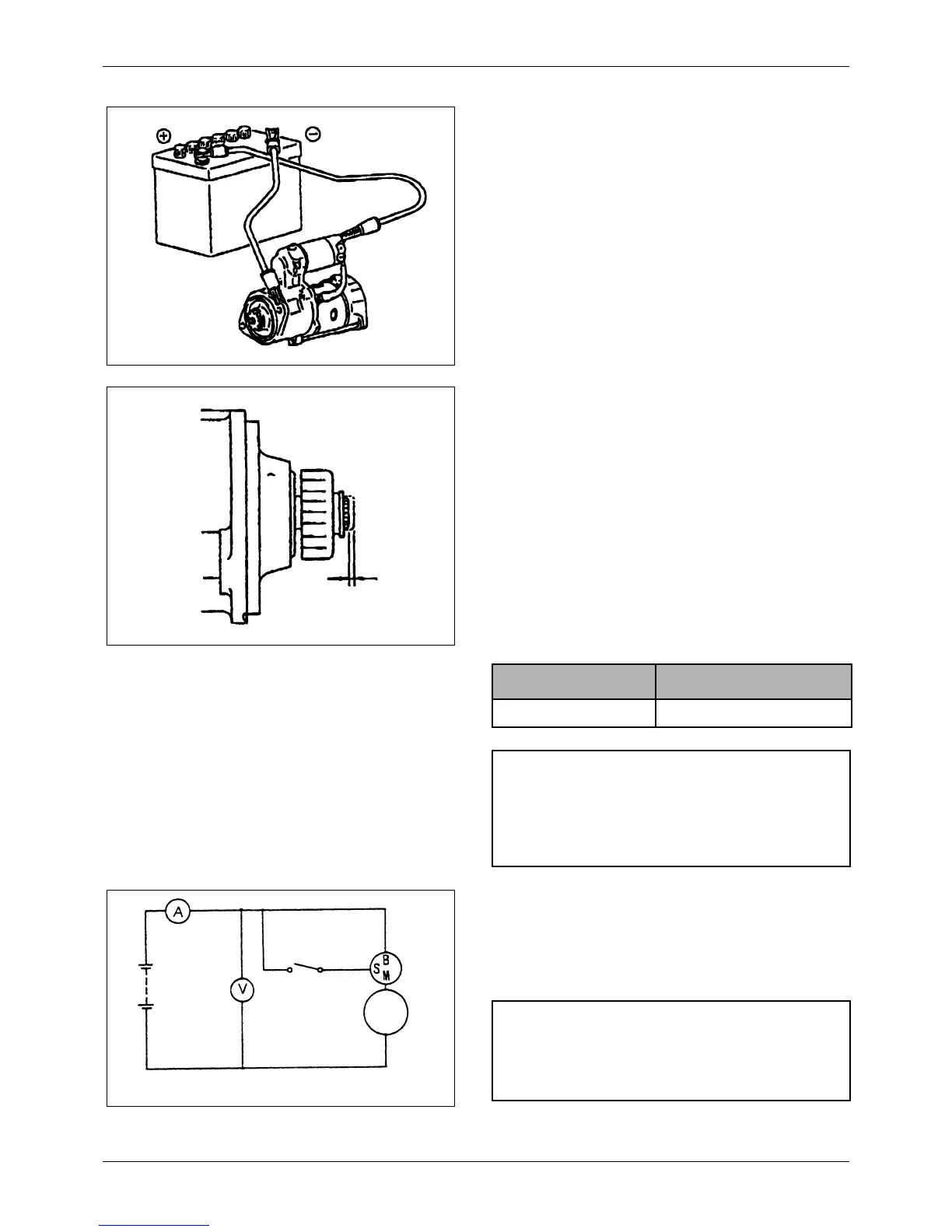

When the pinion gap has been correctly adjusted,

connect an ammeter and a voltmeter between the

starter motor and battery as shown in the drawing, then

check the starter’s no-load characteristics.

Battery (12V)

S-terminal

M-terminal

Pinion gap

Standard value

Pinion gap 0.5 – 2.0 (0.02 – 0.08)

NOTE

To prevent the solenoid switch coil from overheating,

do not energize the solenoid switch for longer than 10

seconds.

Switch

Battery

(12V)

Voltmeter

Starter

Motor

Ammeter

Switch

CAUTION

Use the thickest wires possible, and tighten each

terminal firmly.

Loading...

Loading...