88 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

ENGLISH

Cylinder Block, Crankshaft, Pistons and

Oil pan

ASSEMBLY

88 / 195

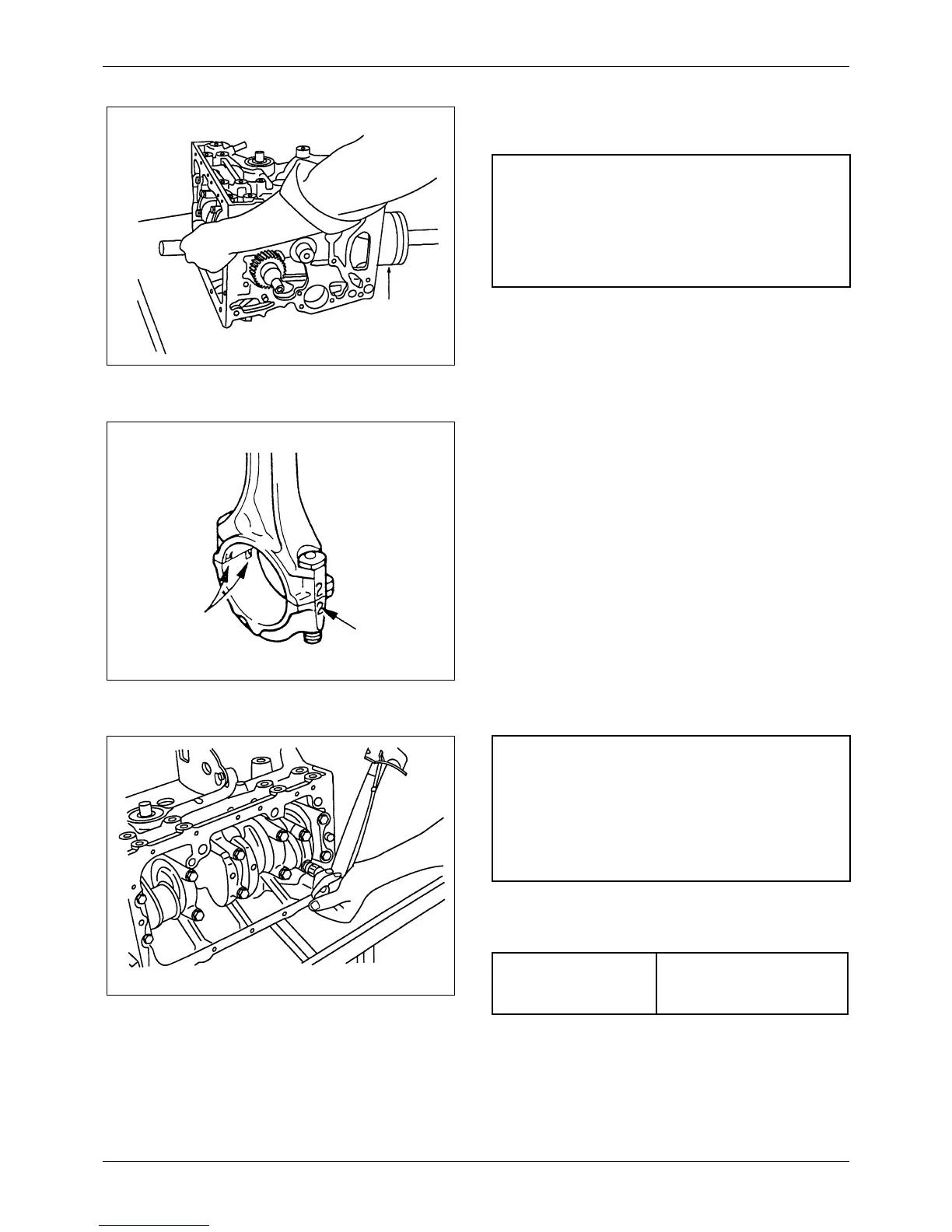

6. Using a piston guide (commercially available), put

the piston and connecting rod into the cylinder

from the top of the cylinder block.

20.8 Connecting rod cap

installation

1. Push the piston into position until the big end of the

connecting rod is put into position over the

crankpin. Then turn the crankshaft 180° while

pushing on the top of the piston.

2. Install the lower half of the connecting rod bearing

in the connecting rod cap, making sure the tab in

the back of the bearing is in the notch of the cap.

3. Install the bearing cap to the connecting rod.

4. Tighten the connecting rod cap nuts in steps to the

specified torque.

5. Check the thrust clearance for the connecting rod

big end.

Figure 128 Installing piston and connecting rod

Piston guide

CAUTION

Do not hit the piston with a hammer to install the

piston and connecting rod. This will put force on the

piston and connecting rod and cause damage to the

piston rings and crankpin..

Figure 129 Installing connecting rod cap

Notches

Cilinder

number

Figure 130 Tightening connecting rod cap nuts

NOTE

• Make sure the number on the cap is the same as

the number on the connecting rod.

• In case of a new connecting rod having no

cylinder number, install the cap to the rod with

the notches on the same side.

Tightening torque

3.55 ± 0.25 kgf·m

(25.7 ± 2 lbf·ft)

[34.8 ± 2.5 N·m]