3. Operation

3.4.3 Dimensional measurement using a scale

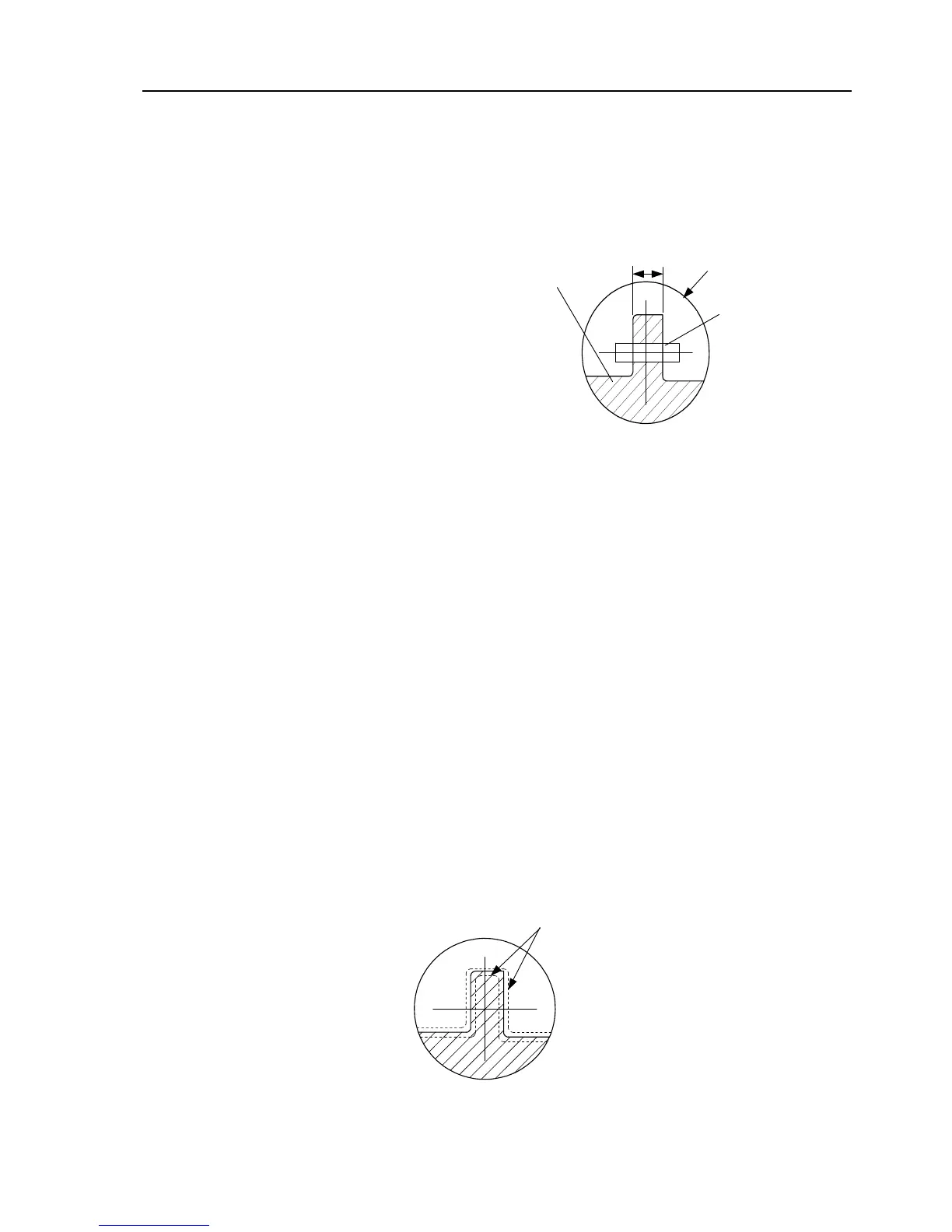

Place the scale on the screen and measure the enlarged image.

Divide the measurements by the magnification of the projection lens to determine the

actual dimensions.

[Example]

Measured value on the screen: 150mm

Projection lens magnification: 10X

150/10=15

Actual dimension of the workpiece: 15mm

Work

ection screen

Scale

Magnified

dimension

y The optional reading scale is ideal for this type of measurement because the graduated

surface of the scale fits on the screen glass, providing parallax-free measurement.

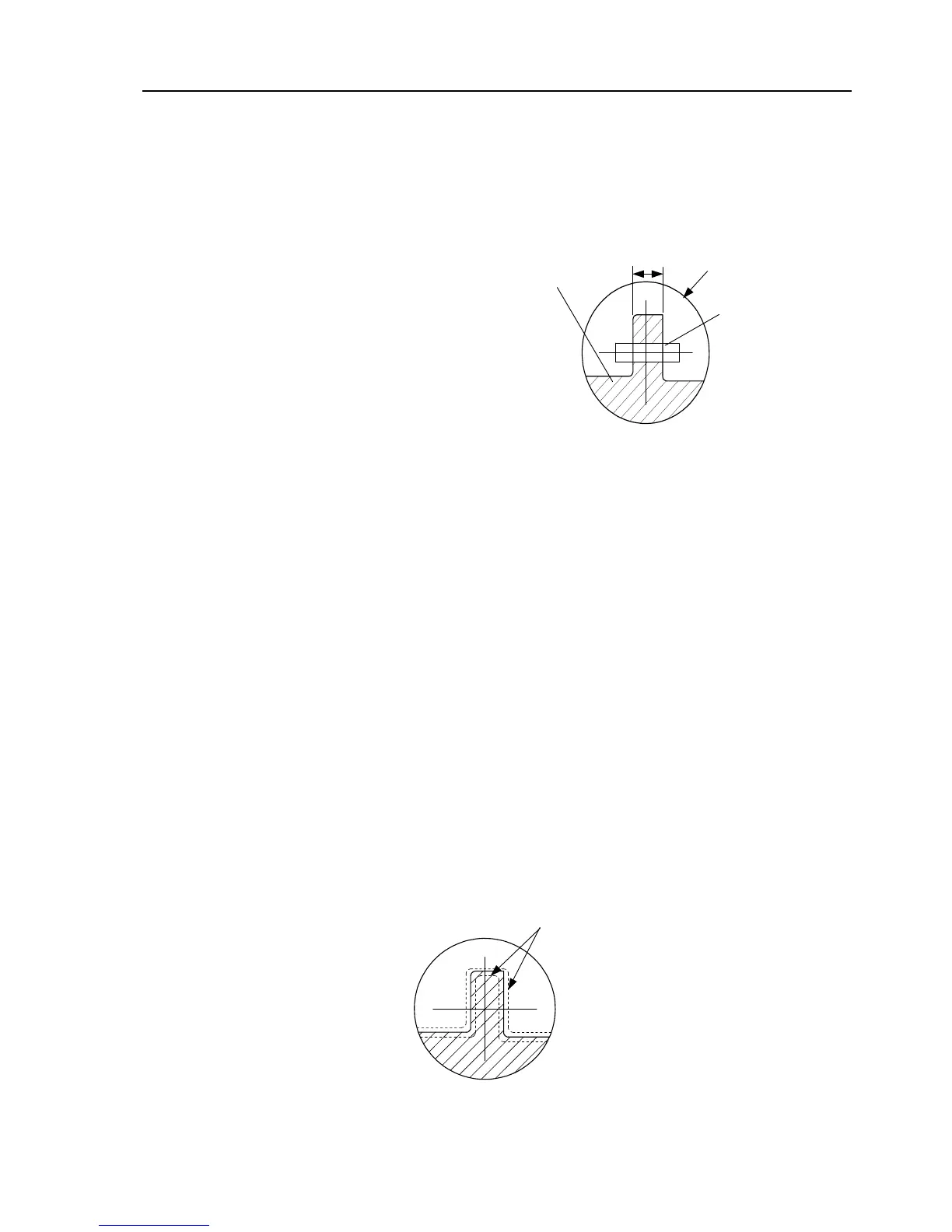

3.4.4 Comparison with an overlay chart

Measurement and inspection are performed by comparing the workpiece image with the

standard overlay chart which is custom-made for the selected magnification. Use this

method for measurement of shapes, multiple points and dimensions.

This method of measurement is suitable for checking a complicated part feature which

cannot be inspected in a simple one-dimensional measurement.

Adding tolerance lines onto the standard overlay chart will improve inspection efficiency,

since workpieces can be inspected with reference to these lines.

Standard charts can be made from the workpiece blue print, or the master workpiece

image projected on the screen. Use transparent or semi-transparent tracing sheets(or

film) to make them. For close inspection or for long-term storage, plastic tracing sheets

are recommended because of their greater dimensional stability.

Tolerance lines

No.99MBA043A 3 - 15

Loading...

Loading...