English – 13

5

STARTING THE AUTOMATION AND CHECKING THE CONNECTIONS

5.1 - Connecting the automation to the mains electricity

To connect SPIN to the main electricity, simply insert the plug into a power outlet; if necessary, use a common adapter if the plug version is not

compatible the available socket.

Never cut or remove the cable supplied with SPIN. If it is not already available, the power socket for connecting SPIN must be

made by qualied and experienced personnel in strict observance of current legislation, standards and regulations. The power

supply line must be protected against short-circuits and ground leakage; a device must be provided to enable disconnection of

the power supply during the installation and maintenance of SPIN (the plug with outlet are suitable for this purpose).

01. Proceed as described below:

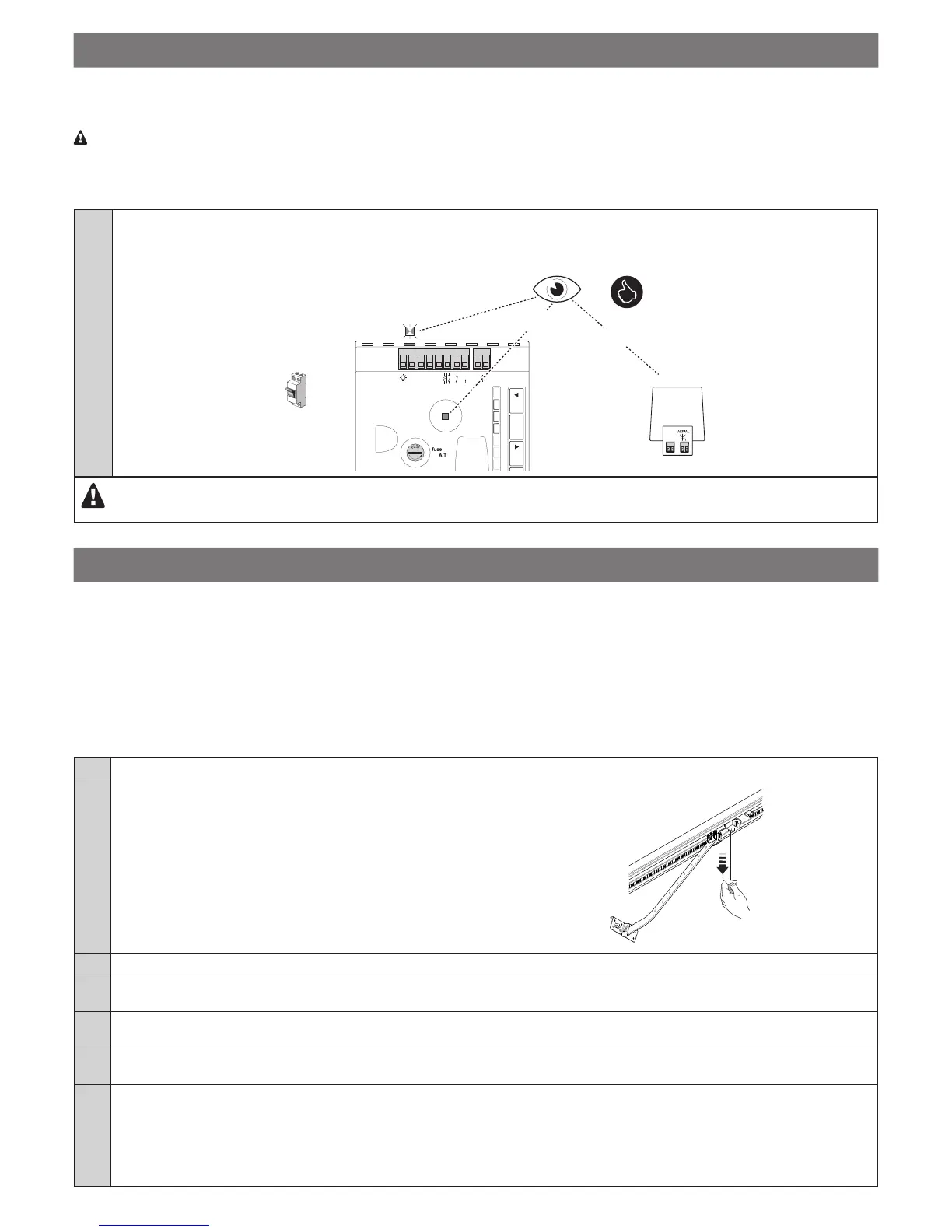

• Make sure that the green “OK” LED ashes regularly, with one ash per second.

• Check that the motor does not control the movement of the door and that the ashing light and courtesy light are off.

ON

FLASH

OFF

2

Flash

8 7 6 5 4 3 2 1

Photo Test

Photo

GND

Stop

SbS

L1

L2

L3

24 V

Aerial

OpenStop/SetClose

OFF

If the above conditions are not satised, immediately switch off the power supply to the control unit and carefully check the electrical

connections. Additional useful information on troubleshooting can be found in Chapters 9 and 10.

6

TESTING AND COMMISSIONING

These are the most important phases in the automation’s arrangement to ensure maximum system safety.

They must be carried out by a qualied and expert technician who must dene the necessary tests to verify the solutions adopted to counter

any risks present, and check compliance with the laws, regulations and standards: in particular, with all the requirements of the EN 13241-1, EN

12445 and EN 12453 standards.

6.1 - Testing

Before running the testing procedure, it is rst necessary to have completed the “device acquisition” procedure (see Paragraph 7.2). The testing

procedure can also be performed as a periodic check of the automation devices. Each component of the system (sensitive edges, photocells,

emergency stop, etc.) requires a specic testing phase; for these devices, observe the procedures given in the respective instruction manuals.

Run the SPIN test as follows:

01. Check that all provisions stated in the “General warnings” chapter have been strictly observed.

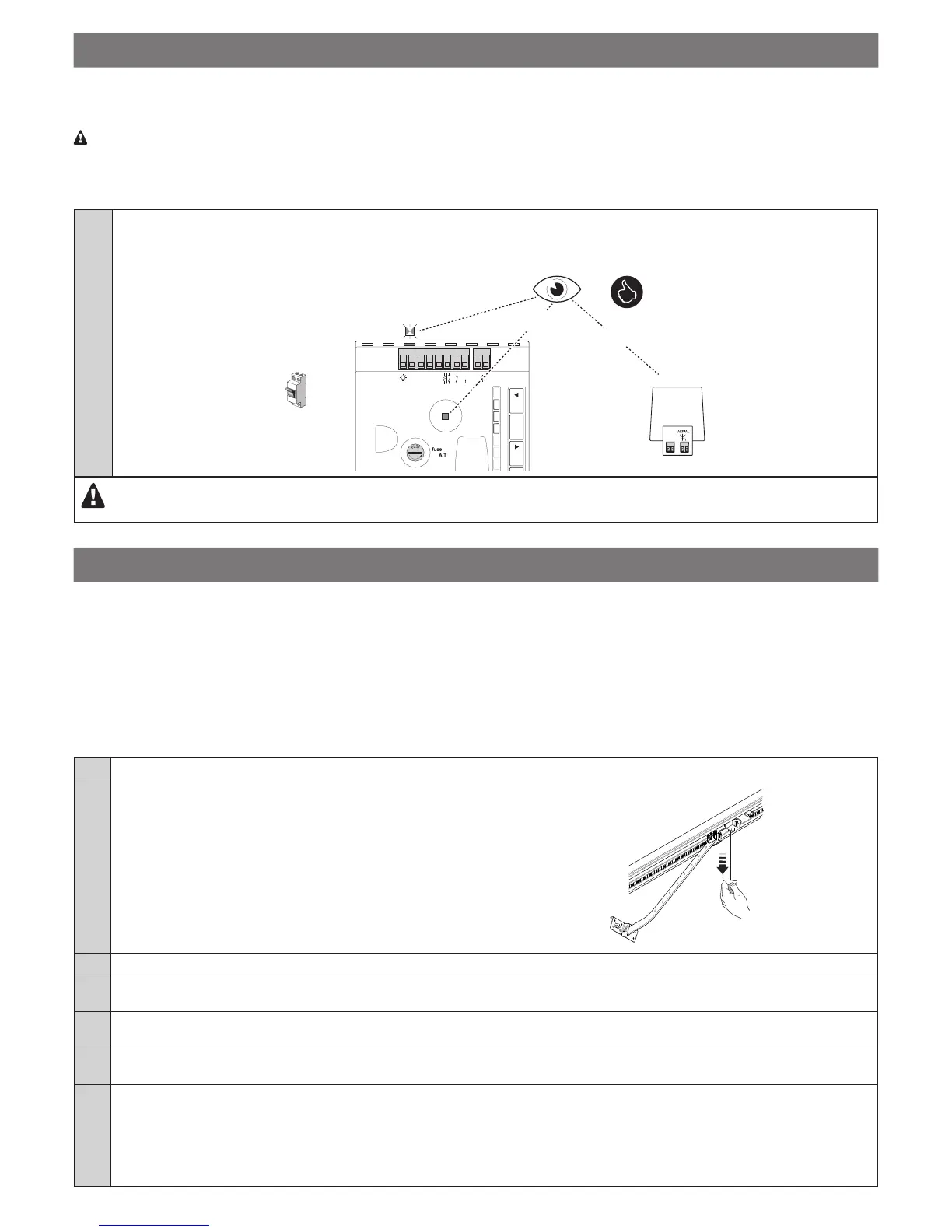

02. Release the door by pulling the release cord and verify whether it

can be moved manually in both the opening and closing directions

with a force no greater than 225 N.

03. Put the motor carriage back.

04. Using the key-operated selector or the transmitter or the control unit buttons, test the opening and closing of the garage door and make

sure that it moves in the intended direction.

05. Perform the test several times to verify that the door moves smoothly, that there are no points of excessive friction and that there are no

defects in the assembly or adjustment.

06. Check the proper operation of all the safety devices, one by one (photocells, safety edges, etc.). In particular, whenever a device is

activated, the green OK LED on the control unit emits 2 faster ashes to conrm that the control unit has recognised the event.

07. Check the operation of the photocells and any interference with other devices:

1 - insert a cylinder with 5 cm diameter and 30 cm length across the line of sight, rst near the TX then near the RX

2 - check that the photocells intervene in any case, switching from the active status to the alarm status and vice-versa

3 - check that their intervention determines the intended response of the control unit: for example, that it causes the movement to invert

during the closing manoeuvre.

Loading...

Loading...