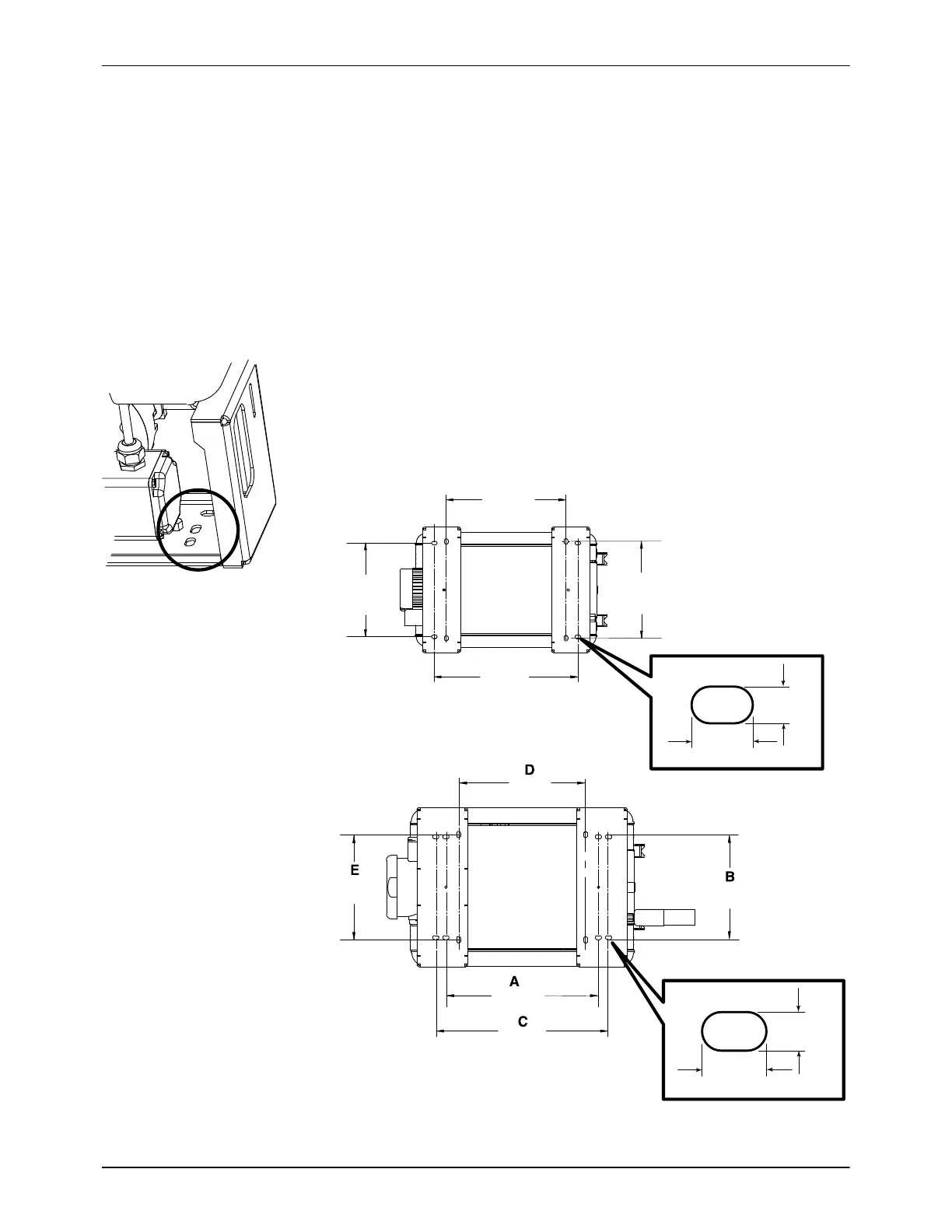

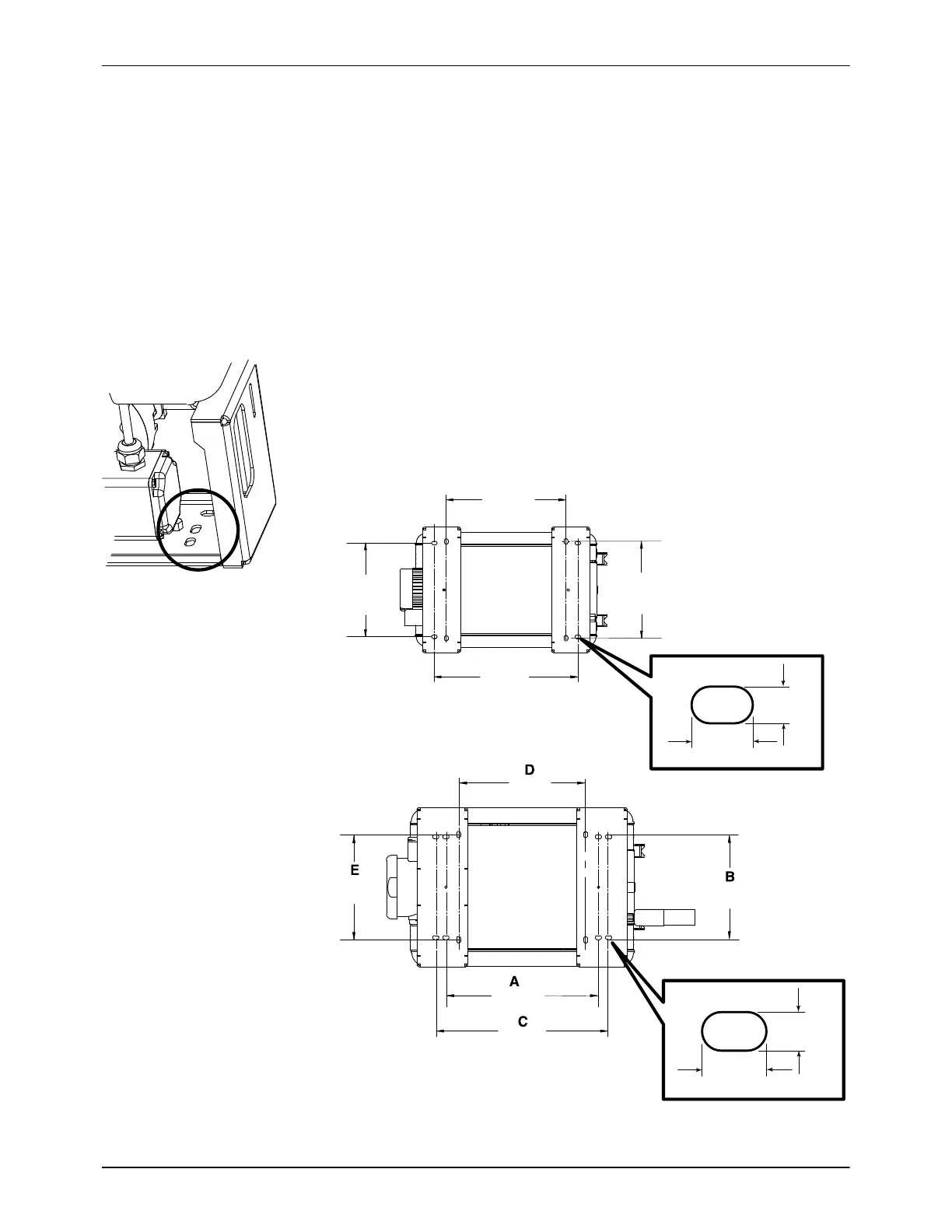

Mounting holes

Installation

3-6

Part 1073401_07

E 2021 Nordson Corporation

Mounting the Melter

Before mounting the melter, ensure that the parent machine or support

structure is level with respect to the floor, provides an even mounting surface,

is not subject to extreme vibration, and is capable of supporting the weight of

the melter, a full tank of hot melt, and the hoses and applicators.

Refer to Section 8, Technical Data, for the weight of the melter. Refer to the

technical data provided by the hot melt manufacturer for information about

the volumetric weight of the hot melt.

To mount the melter

See Figure 3‐3. Use 8 mm (

5

/

16

in.) machine bolts and locking hardware to

secure the melter mounting brackets to the mounting surface.

NOTE: The bolt mounting pattern of DuraBlue melters can be adapted to

that of many other Nordson melters. Refer to Table 3‐2.

F

B

D

A

D4

D10/D16

10 mm

(0.38 in.)

16 mm

(0.63 in.)

432 mm

(17.00 in.)

381 mm

(15.00 in.)

249 mm

(9.80 in.)

318 mm

(12.50 in.)

260 mm

(10.25 in.)

381 mm

(15.00 in.)

318 mm

(12.50 in.)

249 mm

(9.80 in.)

257 mm

(10.12 in.)

14 mm

(0.56 in.)

10 mm

(0.38 in.)

Figure 3-3 Bolt mounting patterns (refer to Table 3-2)

Loading...

Loading...