119

Loop Burnout Alarm Section 4-12

• If the set point is so high or low that it cannot be reached even with a sat-

urated manipulated variable, a temperature deviation may remain even in

a steady state and a loop burnout may be detected.

• Detection is not possible if a fault occurs that causes an increase in tem-

perature while control is being applied to increase the temperature (e.g.,

an SSR short-circuit fault).

• Detection is not possible if a fault occurs that causes a decrease in tem-

perature while control is being applied to decrease the temperature (e.g.,

a heater burnout fault).

Parameters Related to Loop Burnout Alarms

Note Set “None” as the unit for analog inputs.

• A loop burnout alarm can be output by setting the alarm 1 type to 12

(LBA).

• A setting of 12 (LBA) can be set for alarm 2 or alarm 3, but the setting will

be disabled.

• Loop burnouts are not detected during SP ramp operation.

• Loop burnouts are not detected during auto-tuning, manual operation, or

while stopped.

• If the alarm 1 latch is set to ON, the latch will be effective for the loop

burnout alarm.

Automatically Setting

the LBA Detection

Time

• The LBA detection time is automatically set by auto-tuning.

(It is not set automatically, however, for heating/cooling control.)

• If the optimum LBA detection time is not obtained by auto-tuning, set the

LBA Detection Time parameter (advanced function setting level).

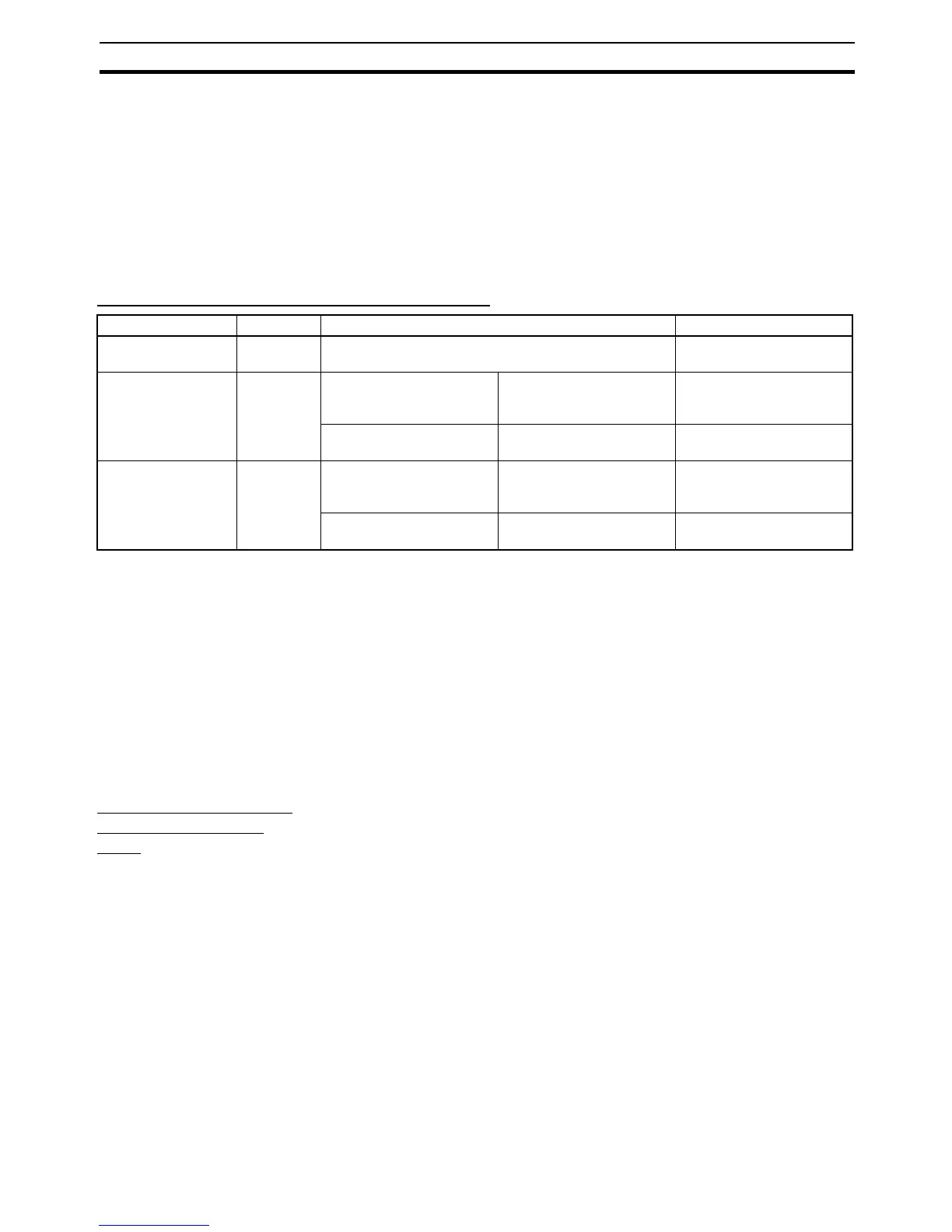

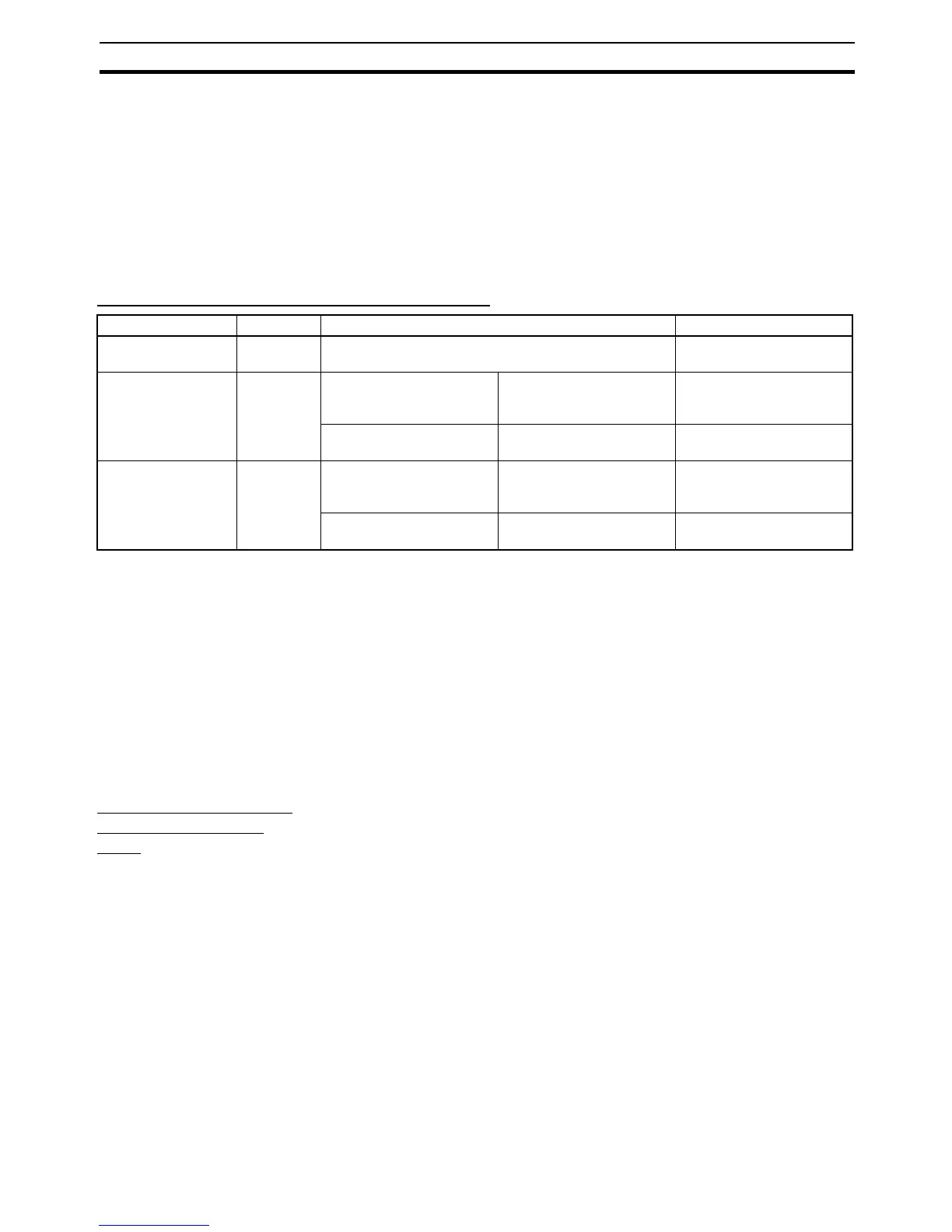

Parameter name Symbol Setting range Remarks

LBA Detection Time lba 0 to 9999 (s) Setting 0 disables the LBA

function.

LBA Level lbal Controllers with Thermo-

couple/Resistance Ther-

mometer Universal Inputs

0.1 to 999.9 (°C/°F) (See

note.)

Default: 8.0 (°C/°F)

Controllers with Analog

Inputs

0.01 to 99.99 (%FS) Default: 10.00% FS

LBA Band lbab Controllers with Thermo-

couple/Resistance Ther-

mometer Universal Inputs

0.0 to 999.9 (°C/°F) (See

note.)

Default: 3.0 (°C/°F)

Controllers with Analog

Inputs

0.00 to 99.99 (%FS) Default: 0.20% FS

Loading...

Loading...