Chapter 6: Connectivity

Figure 6-5 Sample Light Pole Diagram

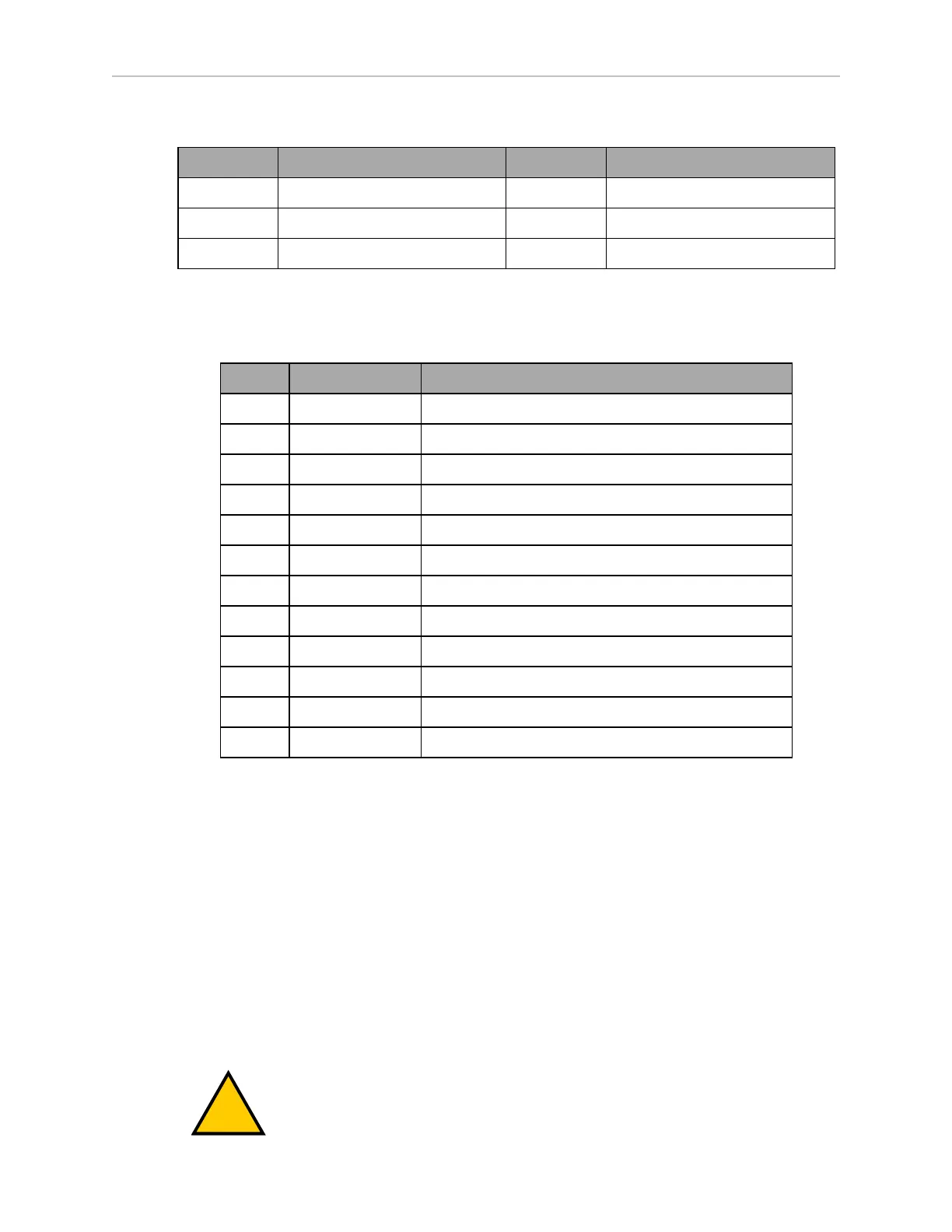

Callout Description Callout Description

A Standard Equipment D Typical User Load

B Wiring Terminal Block E Equivalent Circuit

C User-Supplied Equipment

User Interface (Brake and E-Stop)

The LD-250 Core's User Interface Mini-Fit

®

2 x 7 connector provides circuits for the Brake

release, ON, OFF, and E-Stop buttons.

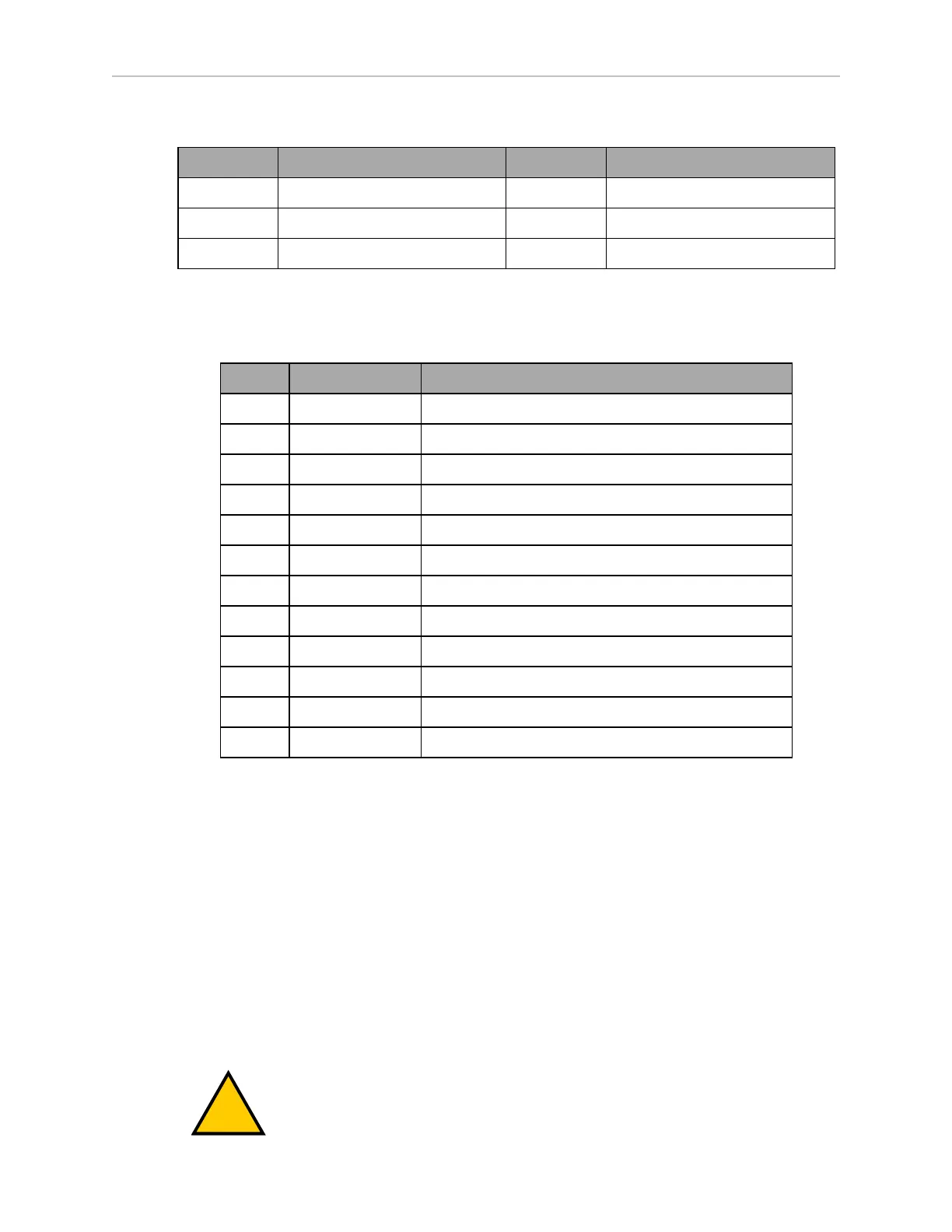

Pin No. Designation Notes

1, 2, 3 FBAT_ALWAYS Fused VBAT @ 500 mA

4 E-STOP_USR_1L Short 4 & 11 to close E-STOP_USR_1

5 E-STOP_USR_2L Short 5 & 12 to close E-STOP_USR_2

6 E-STOP_OUT_1L Pins 6 & 13 short when E-STOP_CH1 is closed

7 E-STOP_OUT_2L Pins 7 & 14 short when E-STOP_CH2 is closed

8 OFF_BUTTON Short to FBAT_ALWAYS to signal OFF (min 1 s pulse)

9 START_BUTTON Short to FBAT_ALWAYS to signal ON (min 1 s pulse)

10 MOTOR_BRAKE Short to FBAT_ALWAYS for manual brake release

11 E-STOP_USR_1H Short 4 & 11 to close E-STOP_USR_1

12 E-STOP_USR_2H Short 5 & 12 to close E-STOP_USR_2

13 E-STOP_OUT_1H Pins 6 & 13 short when E-STOP_CH1 is closed

14 E-STOP_OUT_2H Pins 7 & 14 short when E-STOP_CH2 is closed

NOTE: You can attach an optional, user-supplied, E-Stop button to the E-STOP

port on the User Interfaceconnector.

E-Stop Operational Considerations

Engaging the E-Stop through the external connector (or Operator Panel) faster than 250 ms

causes the drive motors to re-engage when you release the E-Stop.

Motor re-engagement occurs because the LD-250 Core is designed to receive a consistent E-

Stop signal for at least 250 ms. Signals that engage and disengage in under 250 ms cause the

LD-250 Core to interpret the signal as a bumper press, which automatically re-engages the

motors.

No signal on the E-Stop chain can cause the robot to operate while the E-Stop remains

engaged. Thus. you must keep the E-Stop engaged, if your intent is to keep the AMR in an E-

Stop state.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

If you are using a user-supplied E-Stop, you must run the Safety

20472-000 Rev B LD-250 Platform User's Guide 103

Loading...

Loading...