Care and maintenance

12 Care and maintenance

Clean............................................................. daily, more often if in continuous operation

Oil level (lubricating the front parts) ......................................................... daily before use

Oil level (thread lubrication)...................................................................... daily before use

Lubricate the hook ................................................................................... daily before use

Lubricate the bevel gears..................................................................................... annually

Clean the air filter.......................................................................................... once a week

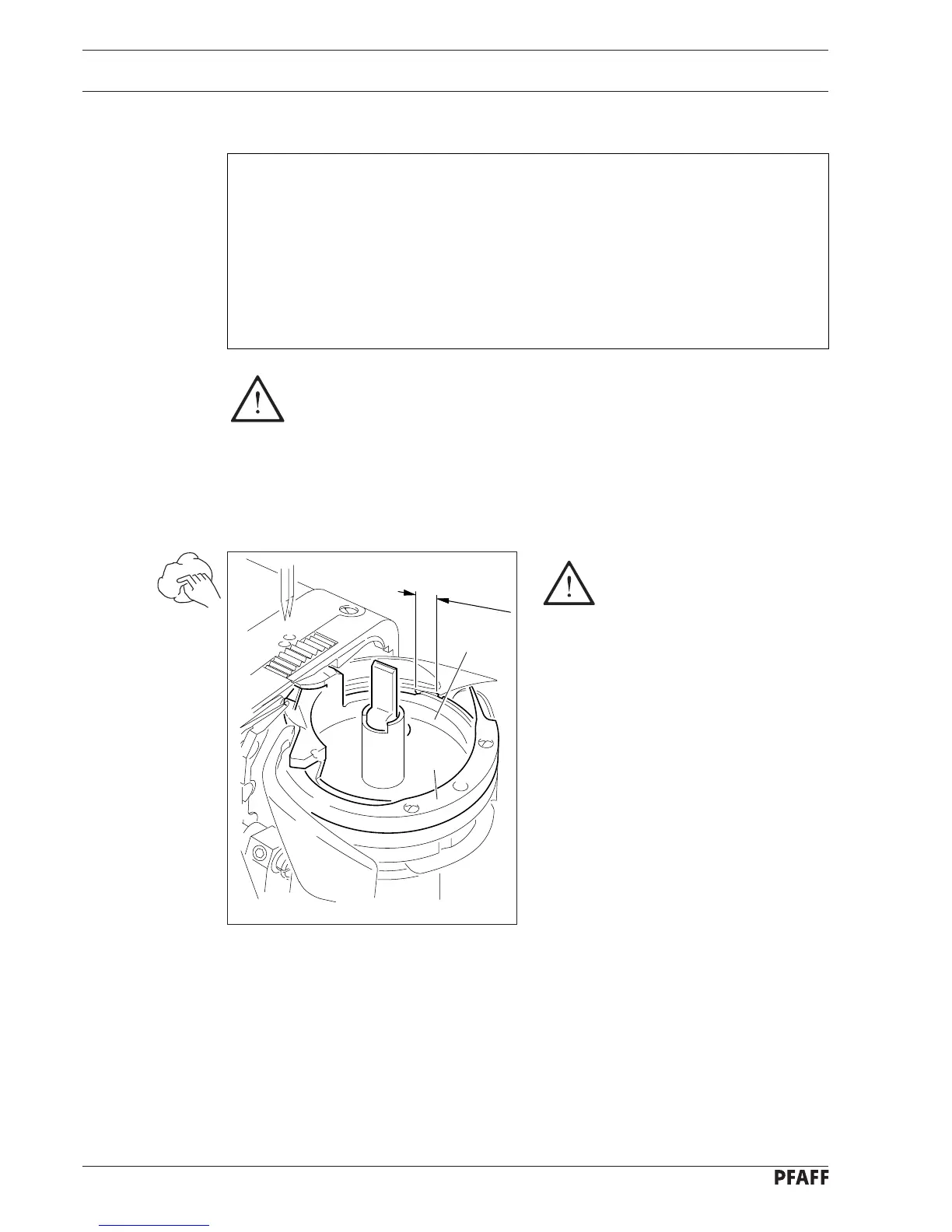

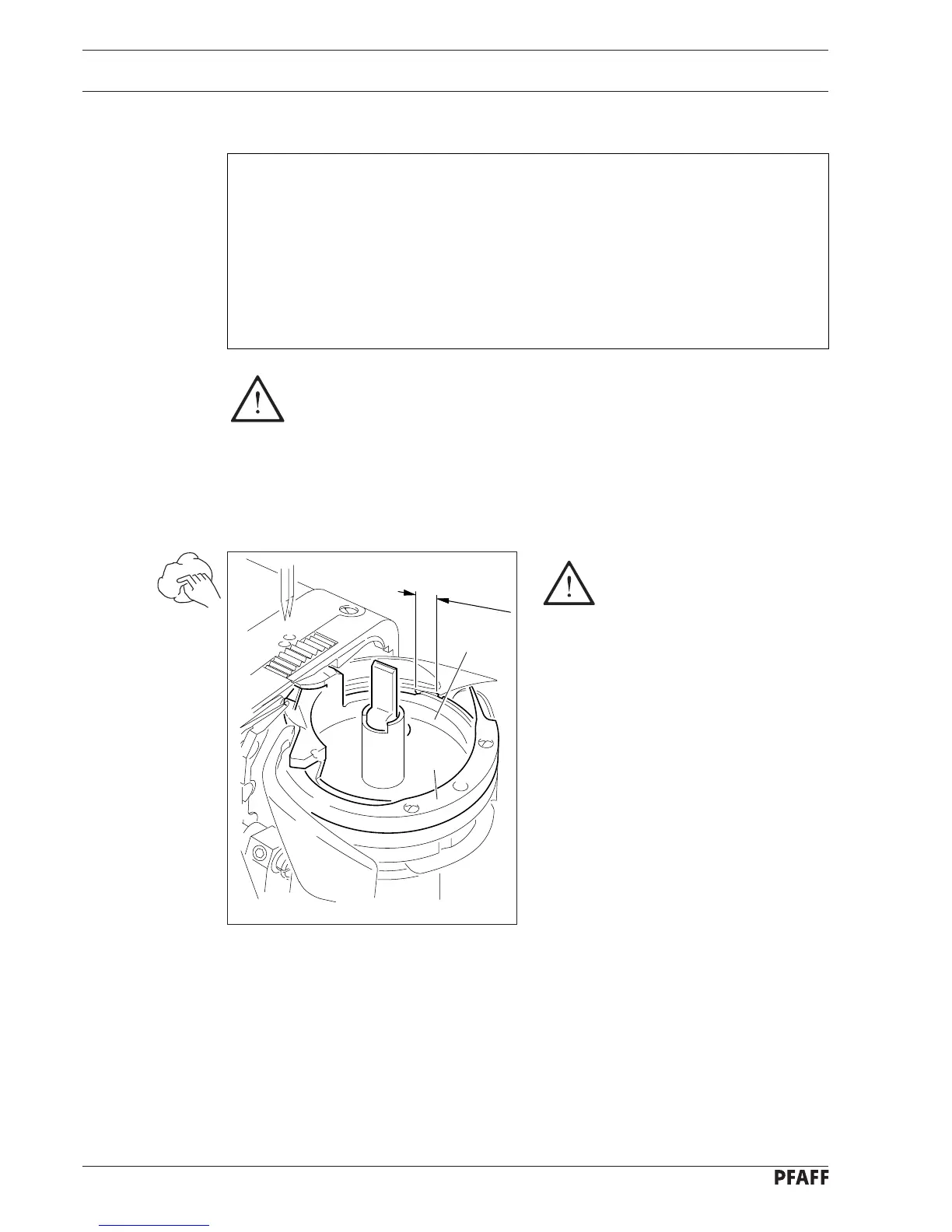

Fig. 12 - 01

These maintenance intervals are calculated for the average running time of a

single shift operation. If the machine is operated more than this, shorter

intervals are recommended.

12.01 Cleaning

Clean the hook and hook compartment daily, more often if in continuous operation.

Turn the machine off!

● Bring the needle bar to its highest

position.

● Open the post cap and remove the bob-

bin case cap and the bobbin.

● Unscrew hook gib 1.

● Turn the handwheel until the point of

bobbin case 2 penetrates into the groove

of the hook race approx. 5 mm.

● Remove bobbin case 2.

● Clean the hook race with paraffin.

● When inserting the bobbin case 2,

ensure that the horn of the bobbin

case 2 engages in the groove of the

needle plate.

● Screw hook gib 1 back on and close the

post cap.

5 mm

2

1

12 - 1

Loading...

Loading...