Adjustment

13.04.16 Roller-presser

Requirement

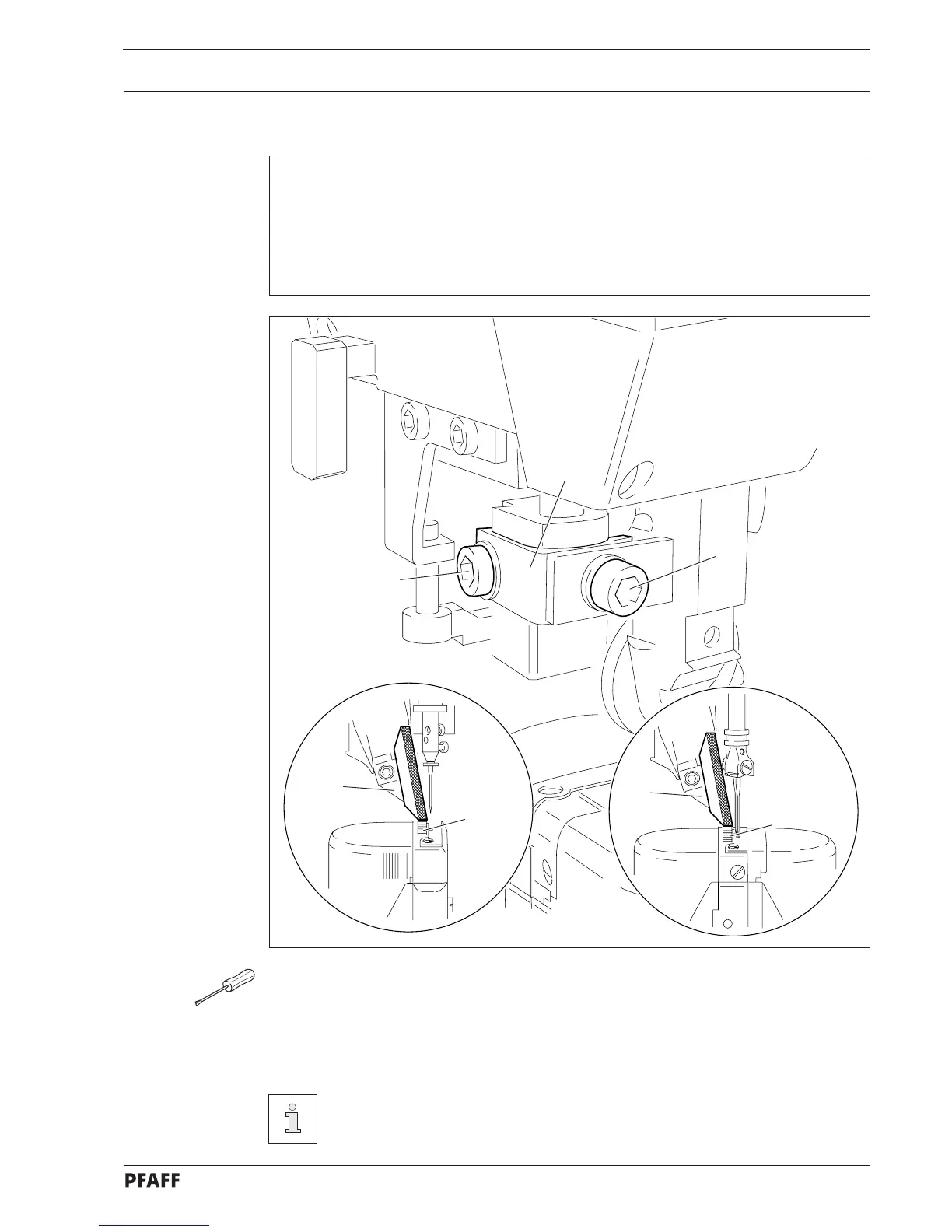

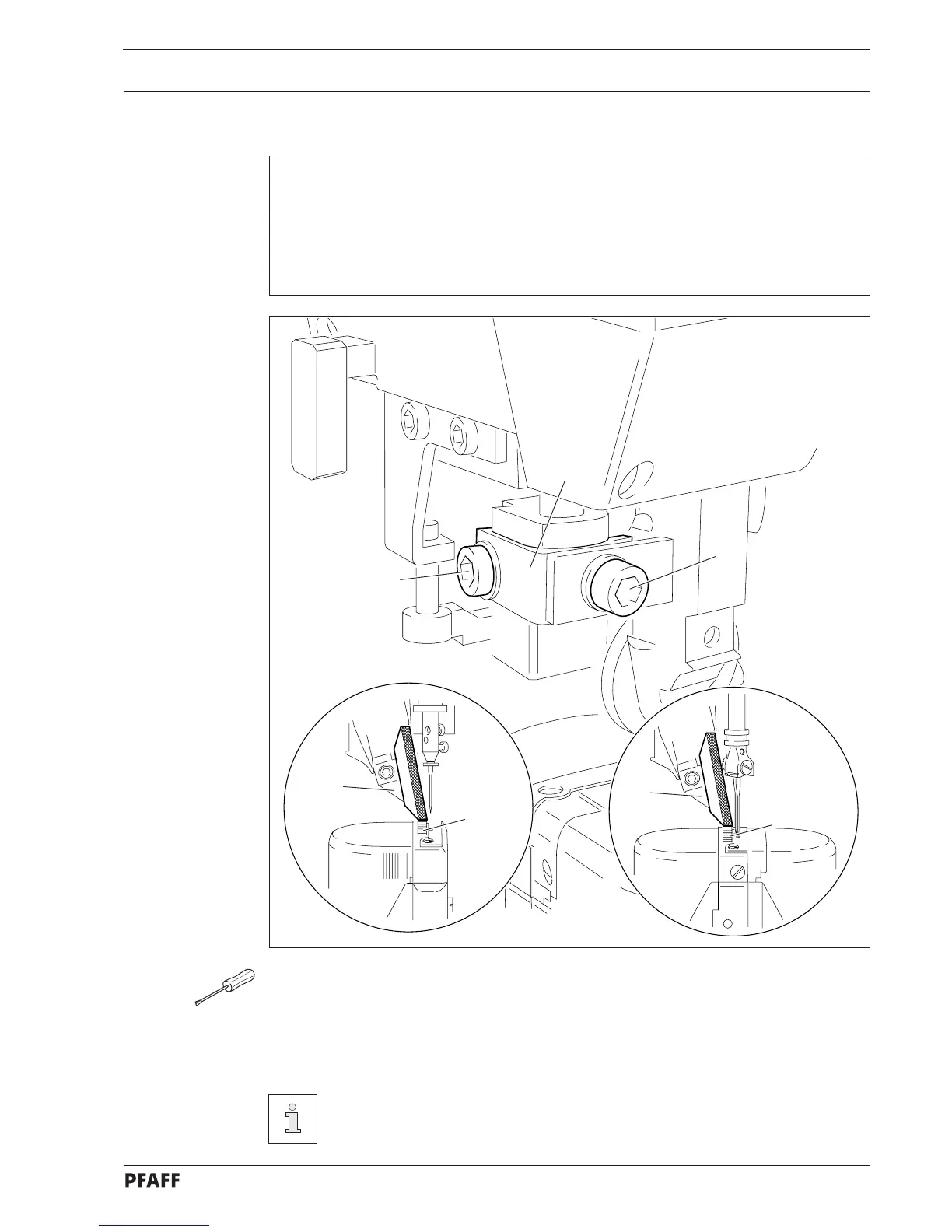

When the roller-presser 1 is resting on the feed wheel 5 it must

1. be parallel to the feed wheel 5 when viewed in the direction of sewing,

2. be in the middle of the ( left ) needle when viewed in the direction of sewing and

3. be as close as possible to the ( left ) needle when viewed in transverse direction of

sewing.

● Raise the roller-presser 1.

● Always observe requirement 1 when carrying out the following adjustments.

● Move the roller-presser 1 ( screw 2 ) in accordance with requirement 2.

● Allow the roller-presser 1 to come to rest on the feed wheel 5.

● Move the roller-presser bracket 3 ( screw 4 ) in accordance with requirement 3.

When sewing very tight curves the roller-presser 1 should be moved toward

the operator slightly.

Fig. 13 - 15

3

2

4

1

5

1

5

13 - 20

Loading...

Loading...