ADJUSTMENT

PROCEDURES

The following instructions

apply

to

bot

'h

th~

P*a#

260

flat-bed

and

the Pfaff

360

free-arm sewing machine.

Wherever

variations

in

design necessitate differ-

ent

adjustment procedures, each

procedure

will

be

discussed separately. To

check the settings

of

a machine

or

to reset it

after

it

has

been

stripped

and

reassembled, follow

the

procedures outlined below:

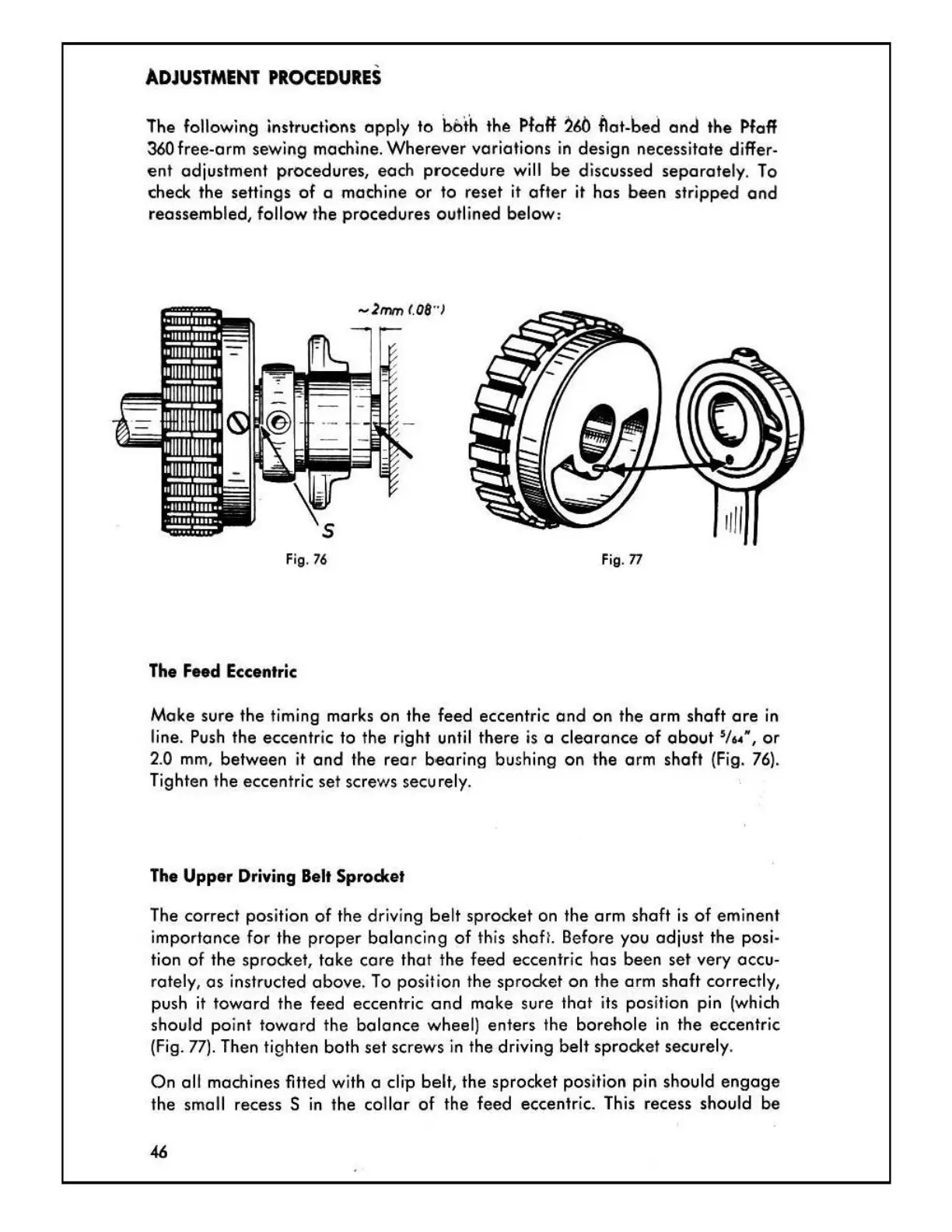

-2mm

f.08'')

Fig.

76

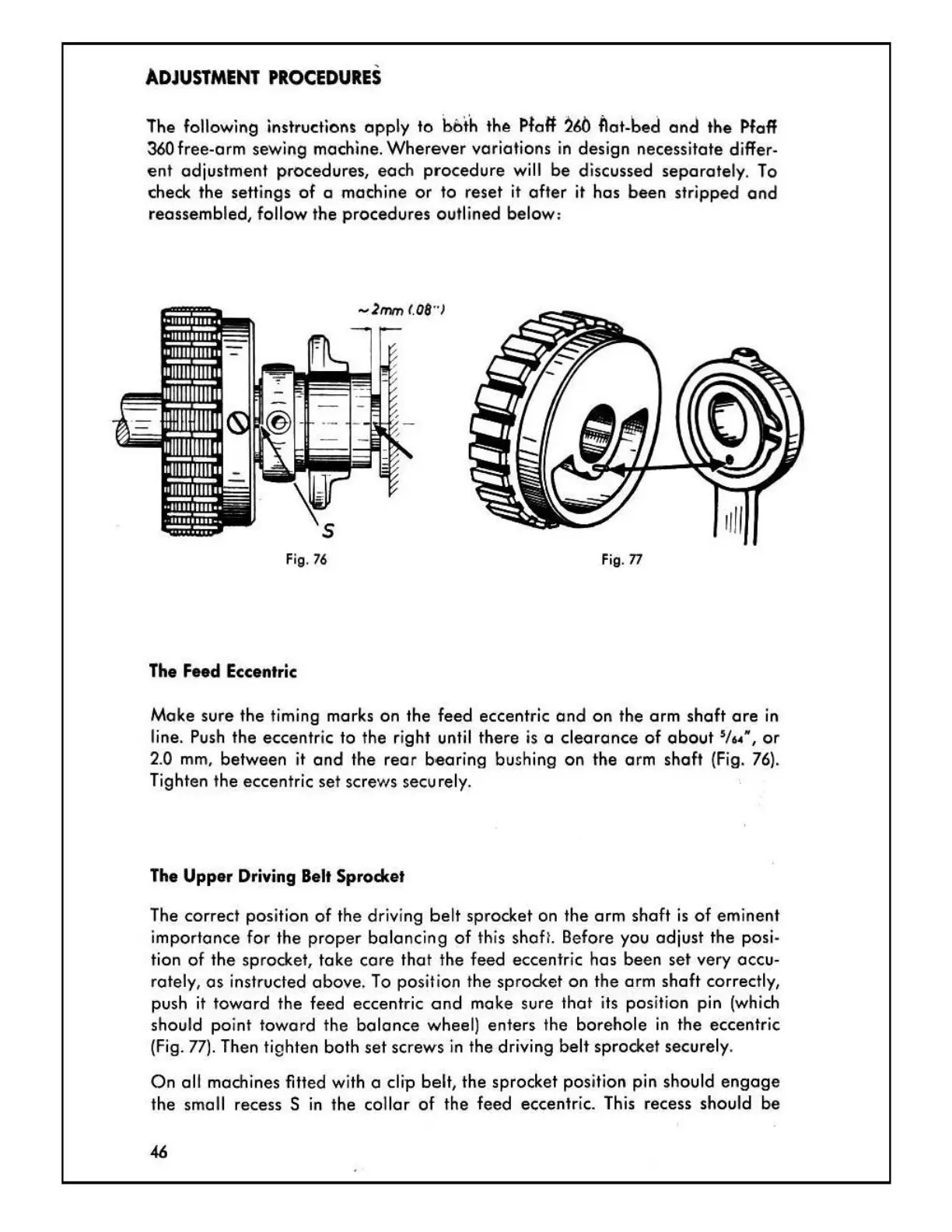

Fig

. n

The Feed Eccentric

Make

sure

the timing marks on the feed eccentric

and

on the arm

shaft

are

in

line. Push the eccentric to the right until there is a

clearance

of

about

5

/6.·,

or

2.0 mm, between it

and

the

rear

bearing

bushing

on

the arm shaft

(Fig.

76).

Tighten the eccentric set screws securely.

The

Upper

Driving Belt Sprocket

The correct position

of

the driving

belt

sprocket on the arm shaft

is

of

eminent

importance for

the

proper

balancing

of

this shaft. Before you adjust the posi-

tion

of

the

sprocket, toke core that the feed eccentric

has

been

set

very accu-

rately,

as

instructed

above.

To position the sprocket on

the

arm shaft correctly,

push it

toward

the feed eccentric

and

make sure

that

its position pin (which

should point

toward

the

balance

wheel)

enters

the

borehole

in

the eccentric

(Fig.

77).

Then tighten both set screws

in

the driving

belt

sprocket securely.

On

all machines fitted with a clip belt, the sprocket position pin should

engage

the small recess S

in

the

collar

of

the feed eccentric. This recess should

be

46

Loading...

Loading...