Set

stitch length dial G on "0"

and

run the machine. Check

to

see

that the

feed

dog

moves

up

and

down,

but

does

not move bock

and

forth. If

adjustme

nt

is

required,

rotate

the stitch length

regulator

mechanism

to

the right

or

left,

as

appropriate

. Do not

forget

to

tighten the set screw securely which holds the

mechanism

in

place.

Adjustment

of

the stitch length

regulator

mechanism is

greatly

facilitated

by

wrench No. 106300-304 which

can

be

obtained

from Pfaff at

extra

cost.

Ad

justing the Bobbin Winder

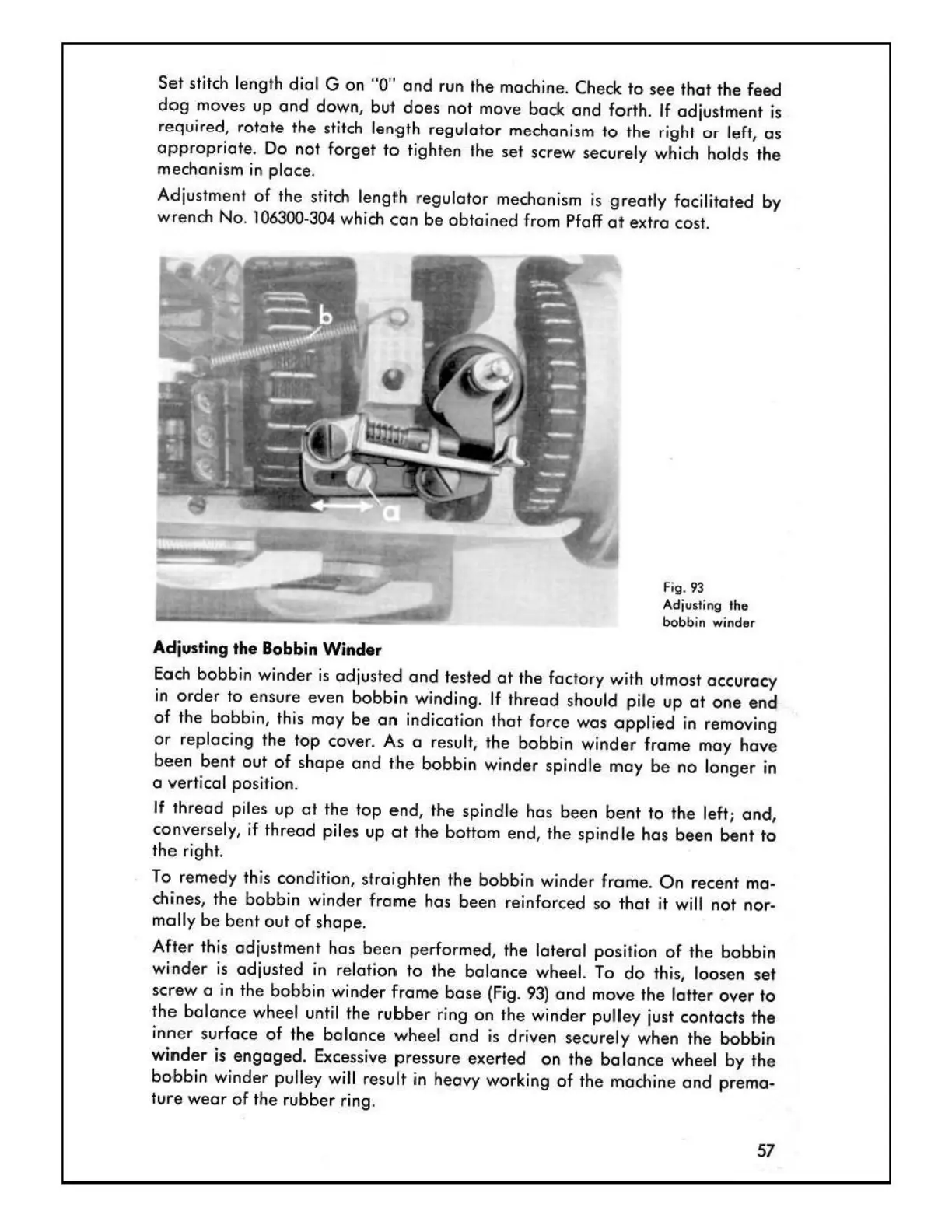

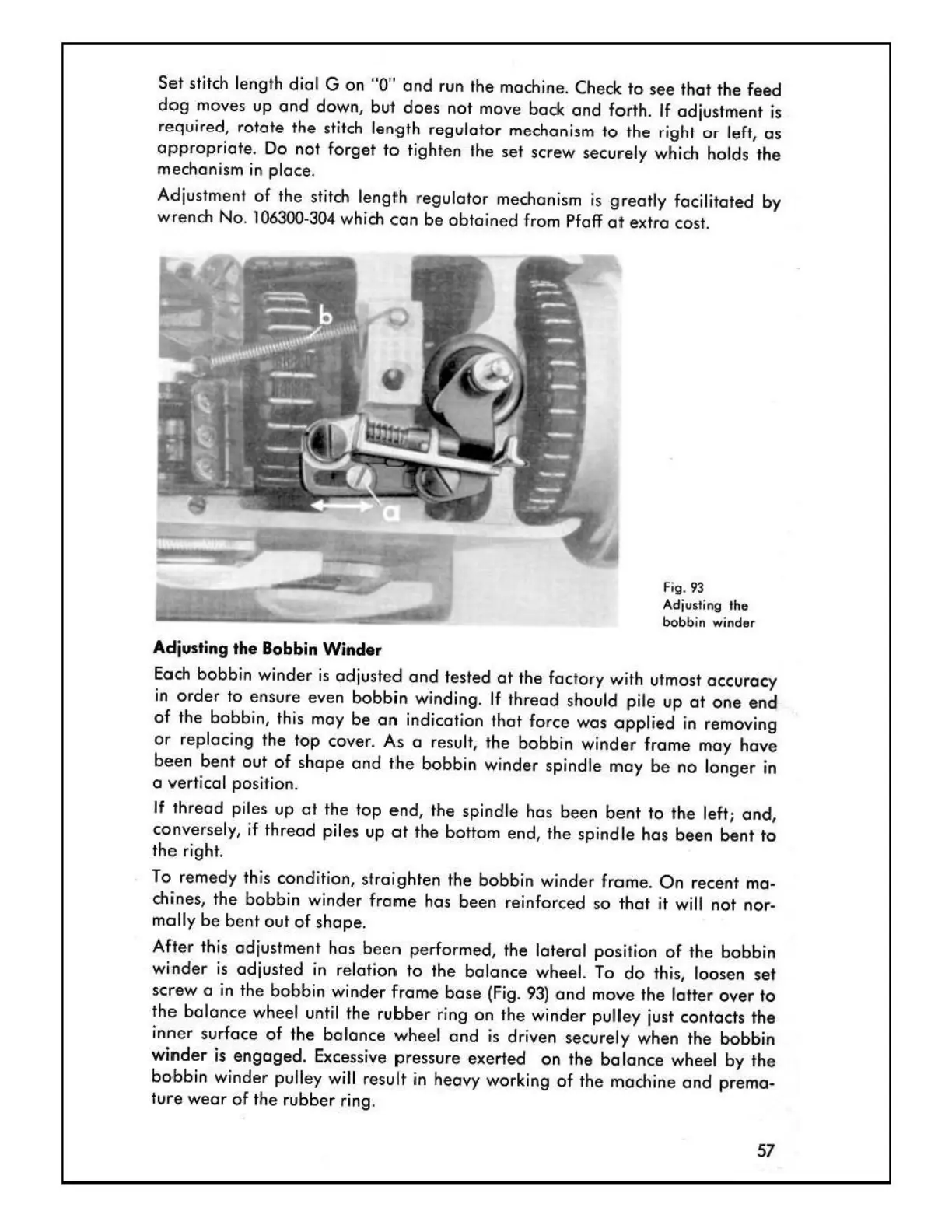

Fig.

93

Adjusting

the

bobbin winder

Each

bobbin

winder

is

adjusted

and

tested

at

the factory with utmost

accuracy

in

order

to

ensure

even

bobbin

winding.

If

thread

should pile

up

at

one

end

of

the bobbin, this may

be

an

indication

that

force was

applied

in

removing

or

replacing the

top

cover

. As a result, the

bobbin

winder

frame

may

have

been

bent

out

of

shape

and

t:

he

bobbin wi

nder

spindle

may

be

no

longer

in

o vertical position.

If

thread

piles up

at

the

top

end,

the spindle

has

been

bent

to

the left;

and,

conversely, if

thread

piles

up

at

the bottom

end,

the spindle

has

been

bent

to

the

right.

To remedy this condition,

straighten

the

bobbin

winder

frame.

On

recent ma-

chines,

the

bobbin

winder

frame

has

been

reinforced so

that

it will

not

nor-

mally

be

bent

out

of

shape.

After

this adjustment has

been

performed, the

lateral

position

of

the

bobbin

winder

is

adjusted

in

relation

to

the

balance

wheel.

To

do

this, loosen

set

screw

a

in

the bobbin

wi

n

der

frame

base

(Fig.

93)

and

move

the Iotter

over

to

the

balance

wheel until the

rubber

ring

on

the

winder

pulley just contacts the

inner

surface

of

the

ba

l

ance

wheel

and

is

driven securely

when

the

bobbin

wi

nder

is

engage

d. Excessive

pressure

exerted on the

balance

wheel

by

the

bobbin

winder

pulley will result in heavy working

of

the

machine

and

prema-

ture

wear

of

the

rubber

ring.

57

Loading...

Loading...