Replacing

the

Top

Cover

When

converting a Pfaff

260

or

360 into

an

Automatic, replace the top cover

on the machine by

the

special top cover which is supplied with the

automatic

embroidery mechanism.

To ensure

that

the

pattern

length regulating

crank

(50561)

enters the regulating

slide

(50368)

smoothly, toke

core

that

the

top

cover

is

replaced perpendicularly

from

above,

and

that

pattern length lever E (Fig.

113)

is

set

between "5"

and

"7".

If

the position

of

pattern

length lever E needs adjustment, loosen the

set

screw

on

the driving

crank

(50558)

and

turn the crank on the stud

of

the

pattern

length regulating crank

(50561

),

as

may

be

required. This adjustment may

also

become

necessary

in

order

to

br

ing the positi

on

of

the pattern length lever

in

line with the numbers

on

its scale.

Checking

the Needle

Position

in

Relation

to

the Needle

Plate

Slot

Disengage

the

automatic

embroidery mechanism by setting lever E

(F

ig. 113)

and

dial C

on

"0". Turn stitch width dial A

to

"0"

and

put

needle position

lever B

in

the

central notch. Turn the

balance

wl\eel

in

order

to

check

whether

the (No.

90)

needle

is

still correctly centered

in

the needle plate slot,

and

whether it will

clear

ei

ther

end

of

the slot when

set

for

its widest bight.

If

the needle

has

to

be recentered

in

the needle

plate

sl

ot

,

proceed

as

instruct-

ed

on

page

69.

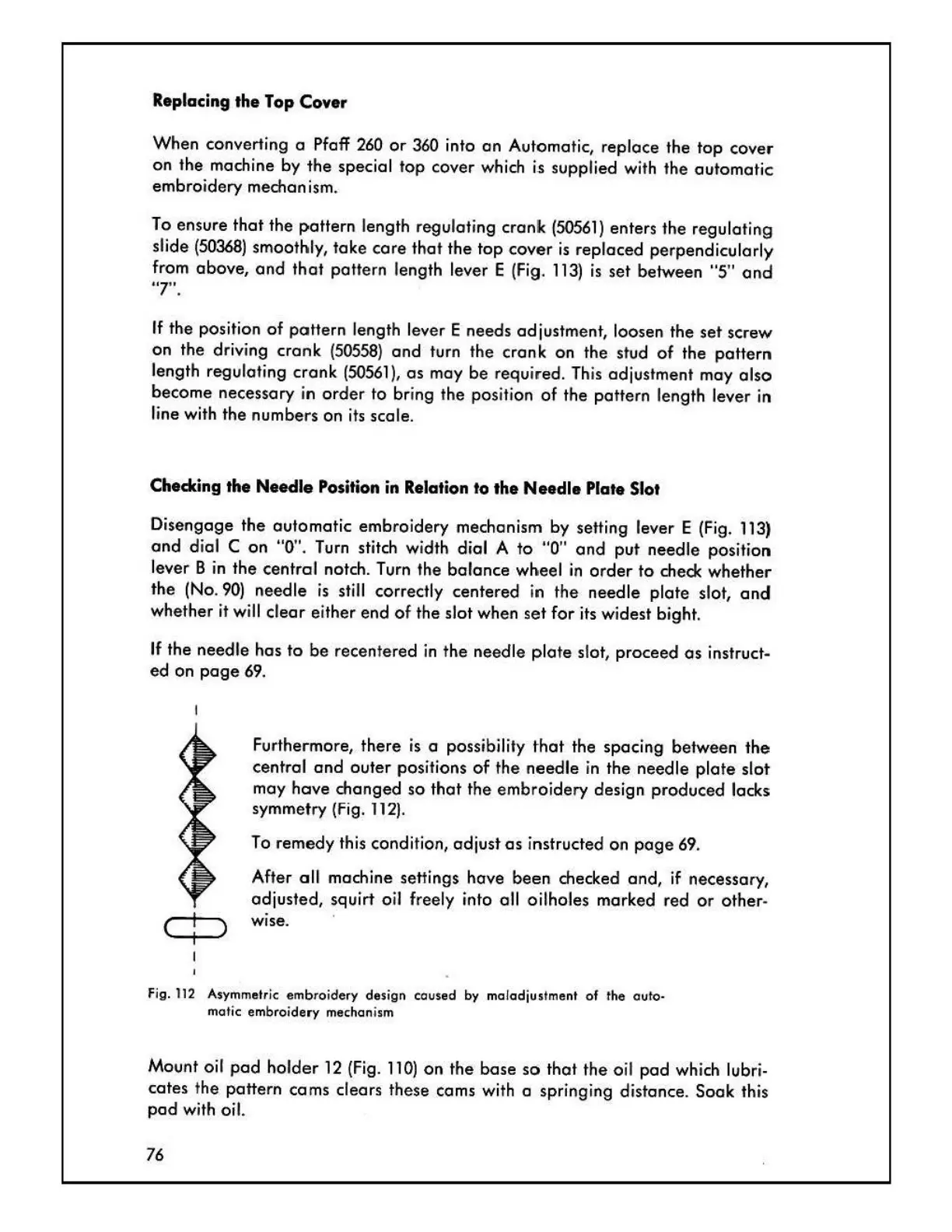

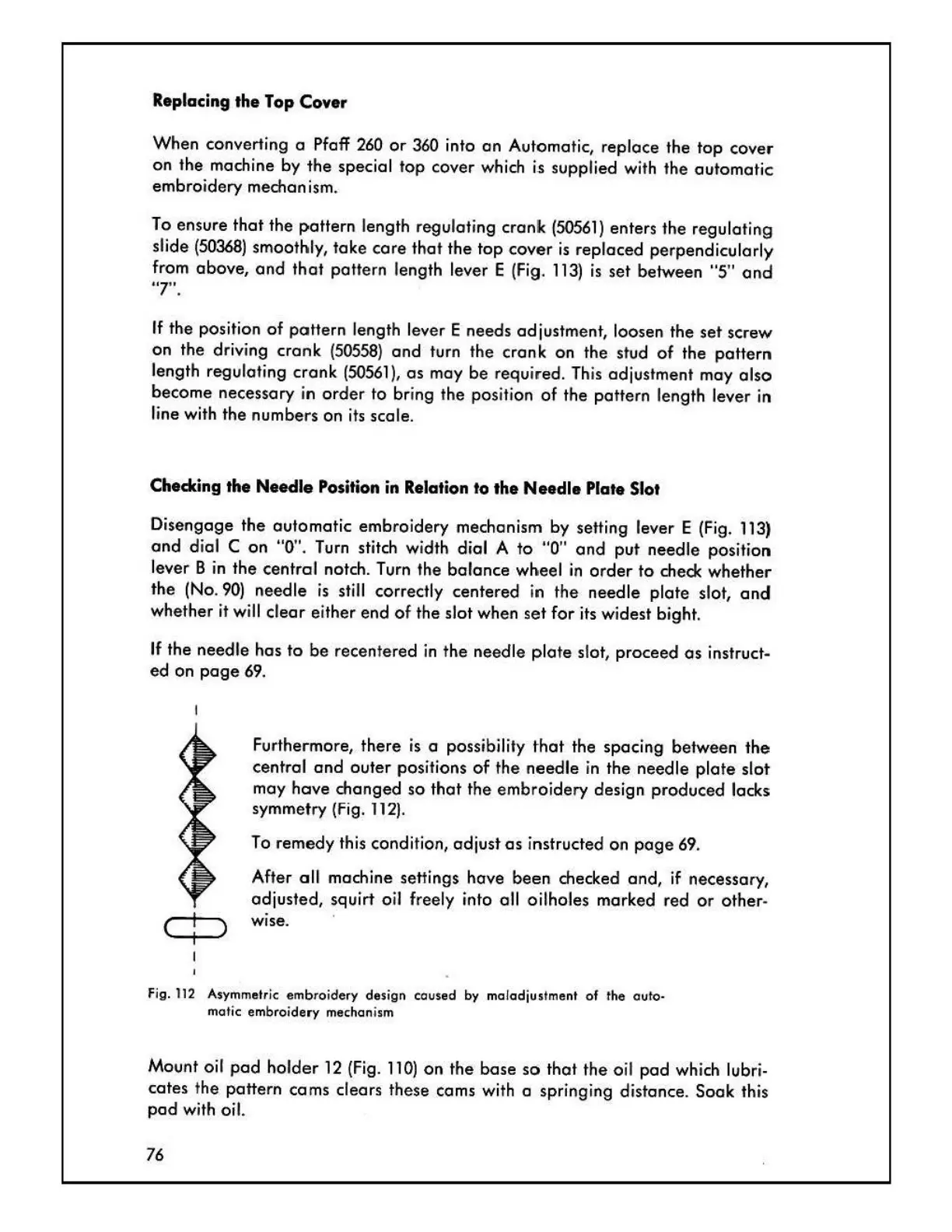

Furthermore,

there

is a possibility

that

the spacing between

the

central

and

outer positions

of

the needle

in

the

needle

plate

slot

may hove

changed

so

that

the

embroidery design produced lacks

symmetry (Fig.

112).

To

remedy this condition,

adjust

as

instructed

on

page

69.

After

all

machine settings have

been

checked

and,

if necessary,

adjusted, squirt oil freely into

all oilholes marked red

or

other-

wtse.

Fig.

112

Asymmetric

embro

idery design caused by malodjustment of the auto·

malic

embro

i

dery

mechanism

Mount oil

pad

holder

12

(Fig.

110)

on

the

base

so

that

the oil

pad

which lubri-

cates

th

e pattern cams clears these cams with a springing distance.

Soak

this

pad

with oil.

76

Loading...

Loading...