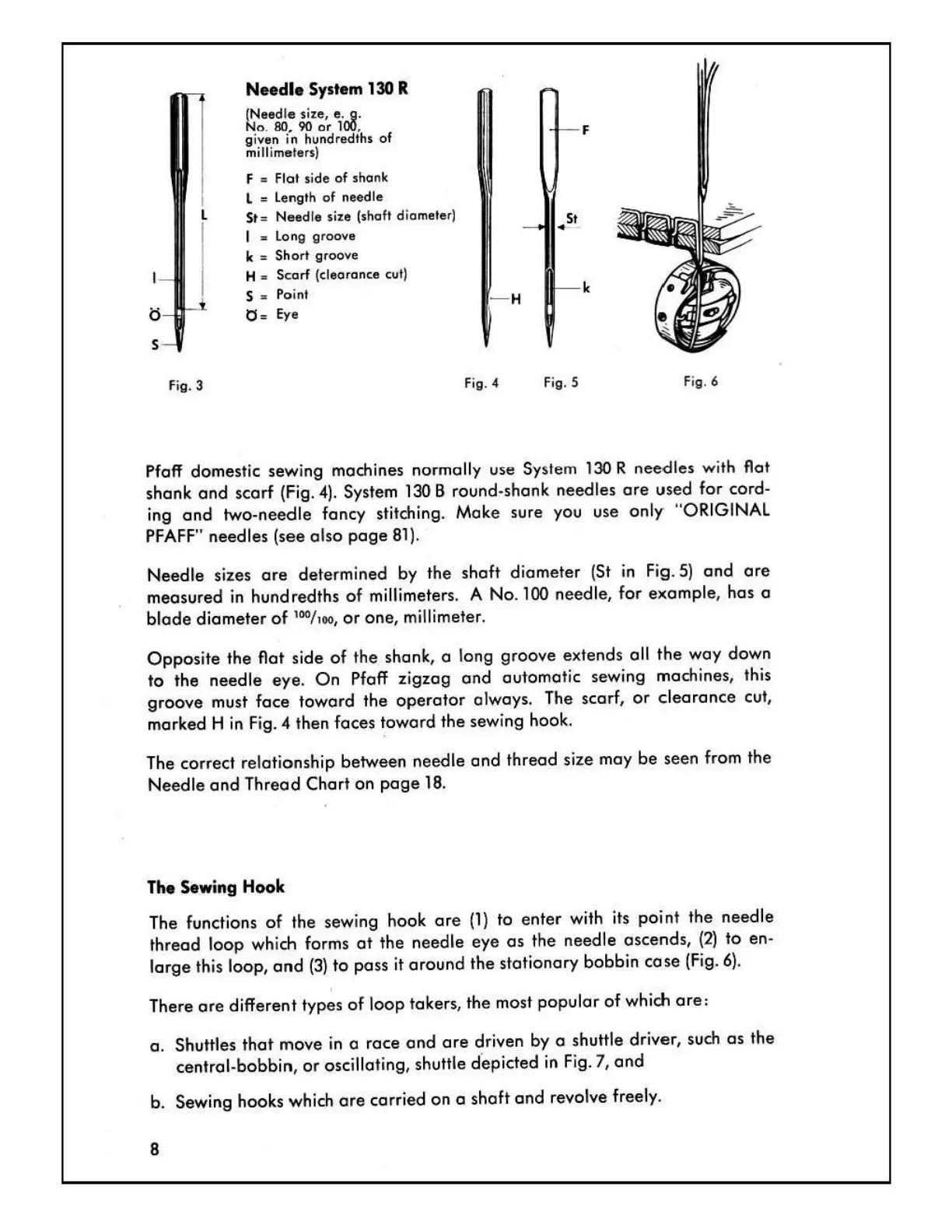

Fig

. 3

Needle

System

130

R

(Needle

size, e. g.

No

. 80, 90

or

1()()_

given in hundredths

of

millimeters)

F = Flat side

of

shank

L

= Length

of

needle

St =

Needle

size (shaft diameter)

I =

long

groove

k =

Short

groove

H

=

Scarf

(cleoronce cut)

S = Point

0=

Eye

Fig. 4 Fig. 5

Fig.

6

Pfaff domestic sewing machines normally use System 130 R

needles

with flat

shank

and

scarf

(Fig.

4).

System 130 B round-shank needles

are

used for cord-

ing

and

two-needle fancy stitching.

Make

sure you use

only

"ORIGINAL

PFAFF

" needles (see a

ls

o

page

81

).

Needle

sizes

are

determined by

the

shaft

diameter

(St

in

Fig.

5)

and

ore

measured

in

hundredths

of

millimeters. A No. 100 needle,

for

example,

has

a

blade

diameter

of

100

/Joo,

or

one, millimeter.

Opposite

the flat side

of

the

shank, a long

groove

extends all

the

way down

to

the needle eye.

On

Pfaff zigzag

and

automatic sewing machines, this

groove

must face

toward

the

operator

always. The scarf,

or

clearance

cut,

marked H

in

Fig. 4 then faces

toward

the sewing hook.

The correct relationship between needle

and

thread size may

be

seen from the

Needle

and

Thread Chart

on

page

18.

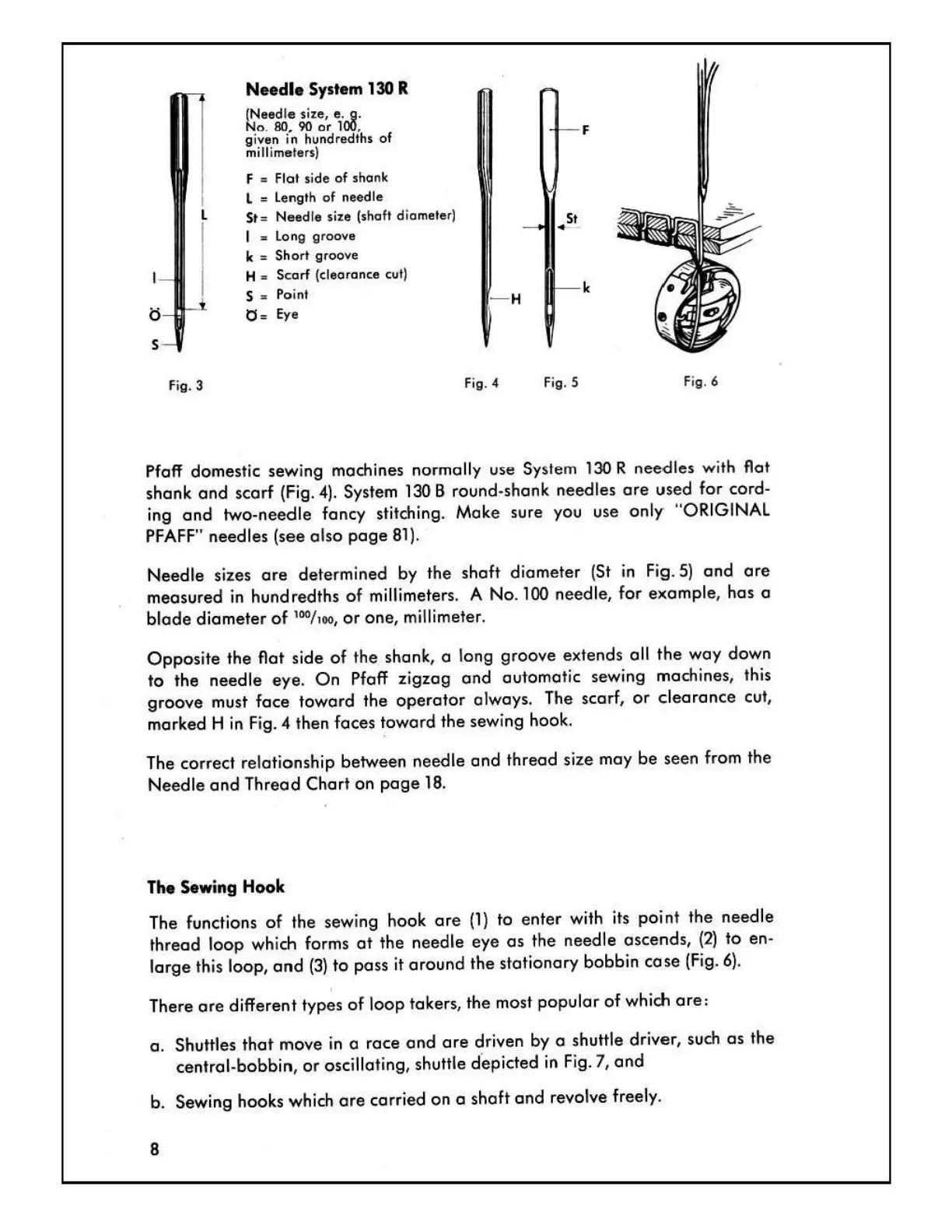

The

Sewing

Hook

The functions

of

the sewing hook

are

(1)

to

enter

with its point

the

needle

thread

loop

which forms

at

the

needle

eye

as

the

needle ascends,

(2)

to

en-

large

this loop,

and

(3)

to

pass

it

around

the stationary bobbin

case

(Fig.

6).

'

There

are

different types

of

loop

takers,

the

most

popular

of

which

ore:

a. Shuttles

that

move

in

a race

and

are

driven by a shuttle driver, such

as

the

central-bobbin,

or

oscillating, shuttle d·epicted

in

Fig. 7,

and

b. Sewing hooks which

ore

carried

on

a

shaft

and

revolve freely.

8

Loading...

Loading...