9.4

BRAKES

9923412 - 2012 Sportsman 400/500 and EFI Tractor Service Manual

© Copyright 2011 Polaris Sales Inc.

Overview: Sportsman Forest 500 (INTL

A12MH50FF)

The Sportsman brake system consists of a complete

hydraulic brake system. All-wheel braking is integrated

into the foot brake and hand brake systems and allows 4

wheel braking from either control separately, or at the

same time.

When the foot brake is applied, all brake calipers are

ac

tive, as braking pressure is routed from the foot brake

master cylinder through the proportioning valve and

distribution block, exiting one line to the front calipers,

while the other line exits the proportioning valve and feeds

the outer line of the rear calipers.

When the hand brake is applied, all brake calipers are

ac

tive, as braking pressure is routed from the hand brake

master cylinder through the distribution block, exiting one

line to the front calipers, while the other line feeds the inner

line of the rear calipers.

When servicing Polaris ATV brake systems, use only

Pol

aris DOT-approved brake fluid.

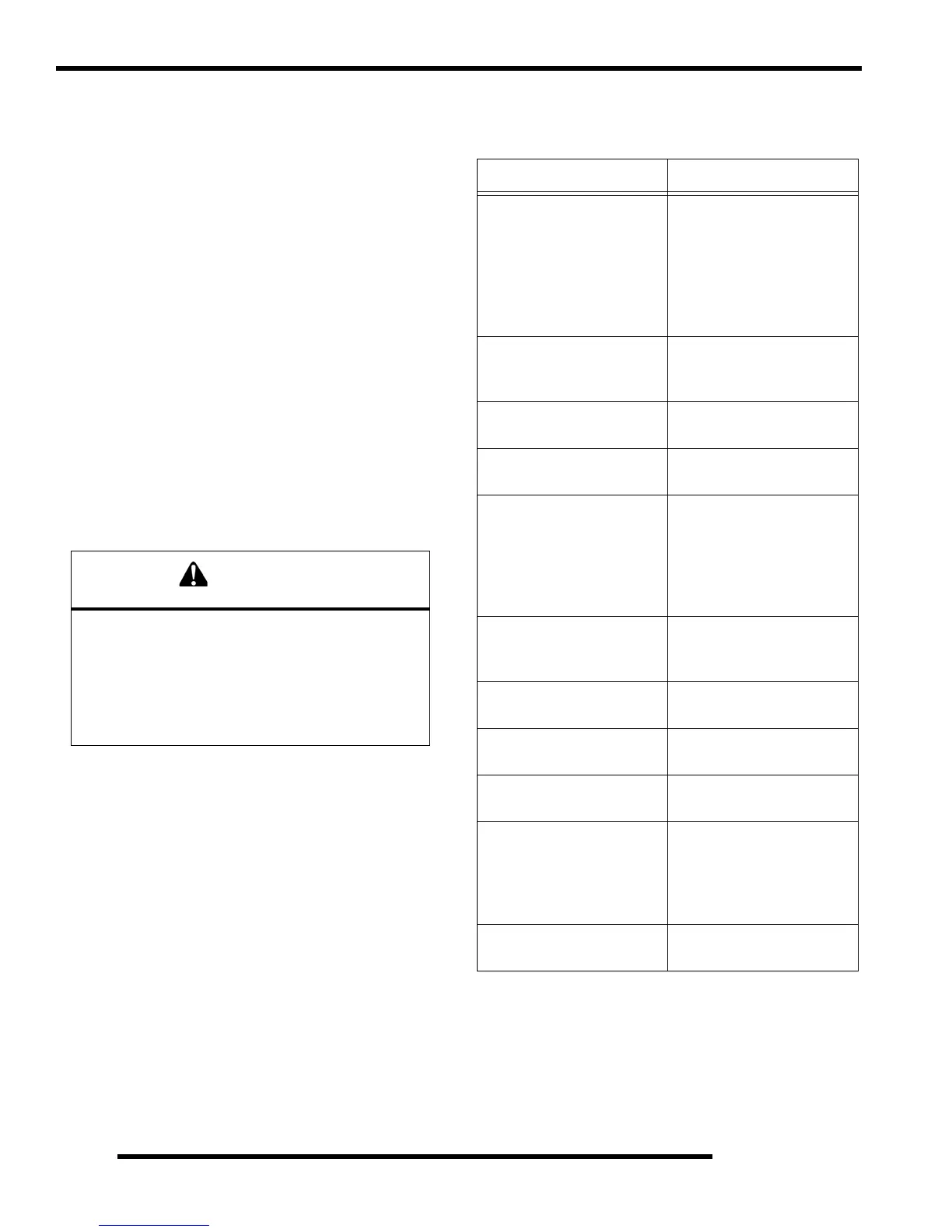

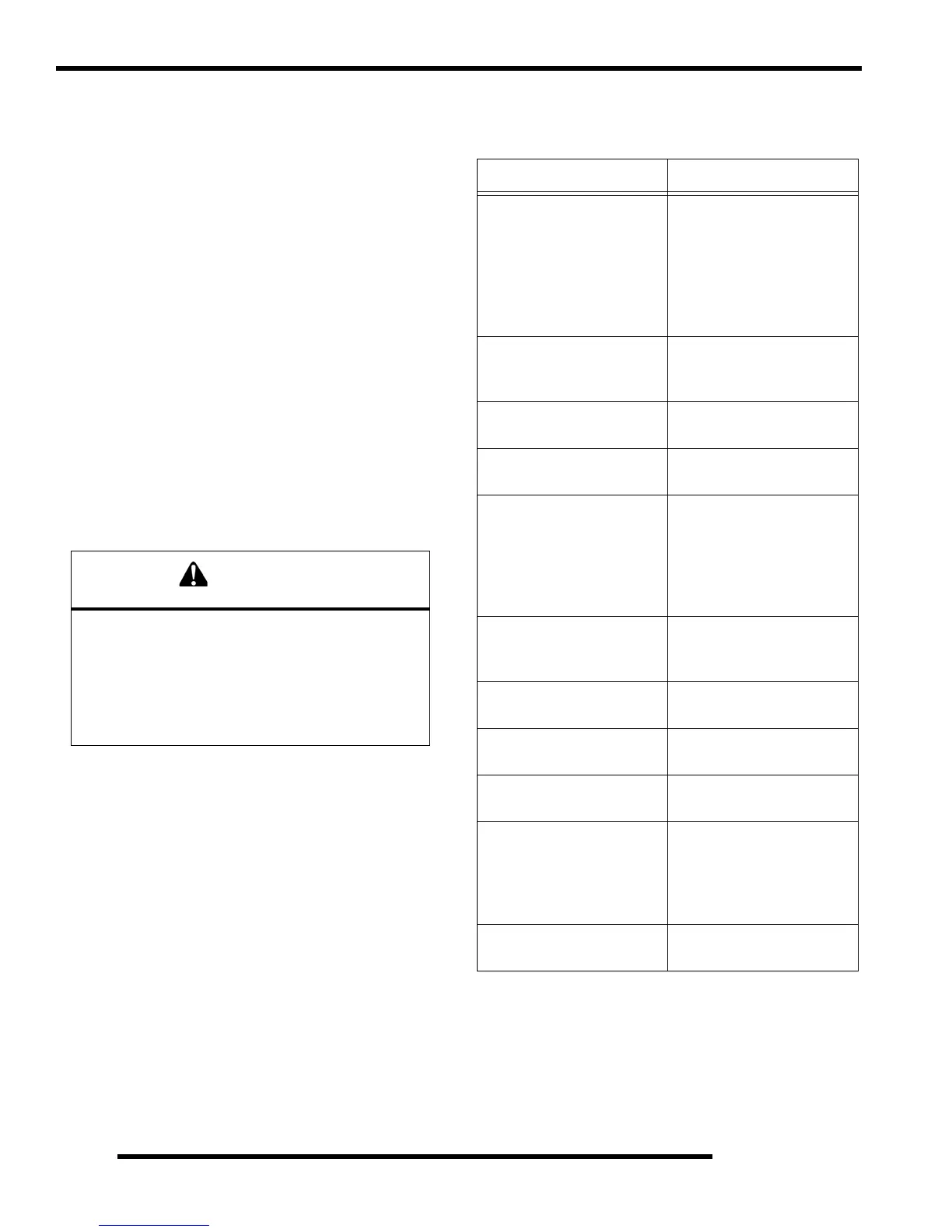

Brake Noise Troubleshooting

Dirt or dust buildup on the brake pads and disc is the most

common cause of brake noise (squeal caused by

vibration). If cleaning does not reduce the occurrence of

brake noise, a product such as Permatex Disc Brake Quiet

can be applied to the back of the pads. Follow directions

on the package. This will keep pads in contact with caliper

piston(s) to reduce the chance of squeaks caused by dirt

or dust.

Once a bottle is opened, use what is necessary and

discard the rest in accordance with local laws. Do

not store or use a partial bottle of brake fluid. Brake

fluid is hygroscopic, meaning it rapidly absorbs

moisture. This causes the boiling temperature of

the brake fluid to drop, which can lead to brake fade

and the possible loss of control.

BRAKE NOISE TROUBLESHOOTING

POSSIBLE CAUSE REMEDY

Dirt, dust, or imbedded

material on pads or disc

Spray disc and pads with

CRC Brake

Kleen

ä or

equivalent non-flammable

aerosol brake cleaner.

Remove pads and/or disc

hub to clean imbedded

material from disc or pads.

Pad(s) dragging on disc

(no

ise or premature pad

wear)

Adjust pad stop

Insufficient lever or pedal

cle

arance

Set to proper level

Master cylinder reservoir

overfilled

Check brake fluid level,

ad

just as needed

Master cylinder

compensating port

restricted, Master cylinder

pisto

n not returning

completely, Caliper

piston(s) not returning

Clean piston(s) seal

Operator error (riding the

bra

ke / park brake

applied)

Educate operator

Loose wheel hub or

bea

rings

Tighten wheel, hub nuts or

replace bearings if worn

Brake disc warped or

ex

cessively worn

Replace disc

Brake disc misaligned or

loose

Inspect and repair as

necessary

Noise is from other source

(cha

in, axle, hub, disc or

wheel)

If noise does not change

wh

en brake is applied

check other sources.

Inspect and repair as

necessary

Wrong pad for

conditions

Change to a softer or

h

arder pad (if available)

Loading...

Loading...