2.16

MAINTENANCE

© Copyright 2011 Polaris Sales Inc.

9923412 - 2012 Sportsman 400/500 and EFI Tractor Service Manual

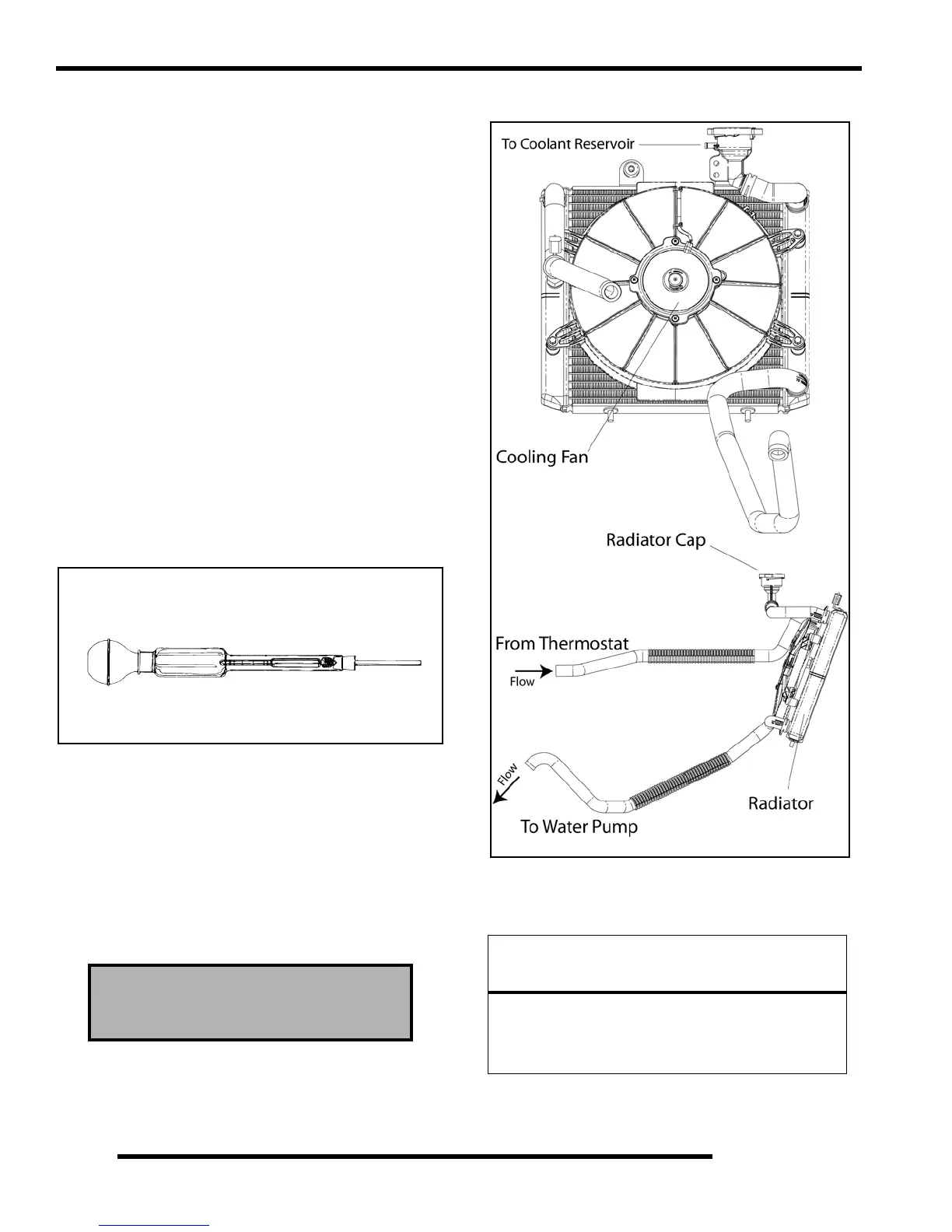

Liquid Cooling System Overview

The engine coolant level is controlled or maintained by the

recovery system. The recovery system components are

the recovery bottle, radiator filler neck, radiator pressure

cap and connecting hose.

As coolant operating temperature increases, the

expanding (heated) excess coolant is forced out of the

radiator past the pressure cap and into the recovery bottle.

As engine coolant temperature decreases the contracting

(cooled) coolant is drawn back up from the tank past the

pressure cap and into the radiator.

Some coolant level drop on new machines is normal as the

system is purging itself of trapped air. Observe coolant

levels often during the break-in period.

Overheating of engine could occur if air is not fully purged

from system.

Polaris Premium 60/40 is already premixed and ready to

use. Do not dilute with water.

Coolant Strength / Type

Test the strength of the coolant using an antifreeze

hydrometer.

• A 50/50 or 60/40 mixture of antifreeze and distilled

water will provide the optimum cooling, corrosion

protection, and antifreeze protection.

• Do not use tap water, straight antifreeze, or

straight water in the system. Tap water contains

minerals and impurities which build up in the

system.

• Straight water or antifreeze may cause the system

to freeze, corrode, or overheat.

Cooling System Hoses

1. Inspect all hoses for cracks, deterioration, abrasion

or leaks. Replace if necessary.

2. Check tightness of all hose clamps.

Polaris 60/40 Anti-Freeze/ Coolant

(PN 2871323)

Do not over-tighten hose clamps at radiator,

or radiator fitting may distort,

causing a restriction to coolant flow.

Radiator hose clamp torque is 36 in. lbs. (4 Nm).

Loading...

Loading...