6. Print the image. Has the problem been resolved?

Yes Finished!

No Contact your service representative.

Delivered Sheets Are Not Aligned

Cause:

When sheets are delivered to the stacker tray, because of paper-to-paper friction, the paddle fails to

pull the trailing edge back into the front guide, resulting in misalignment.

The paper edge stopper also fails to push back the protruding leading edge.

This may occur if:

• Thick (280 g/m

2

[105 lb. Cover] or heavier), uncurled A3 or larger paper is used.

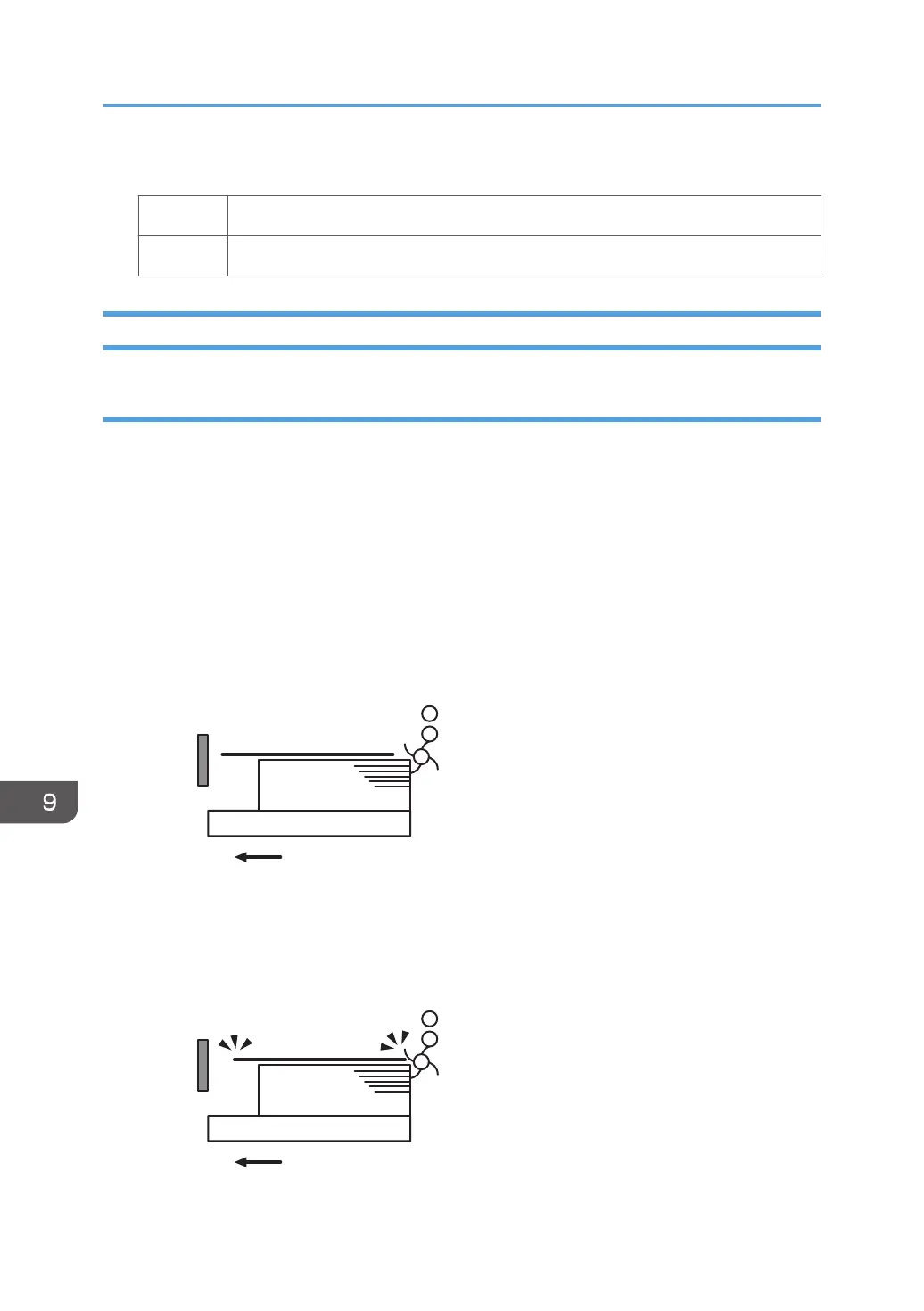

<How the problem occurs>

1. An uncurled sheet is delivered to the stacker shift tray.

Paper feed direction

Stacker shift tray

Paper edge

stopper

Paper exit

Paddle

CEZ577

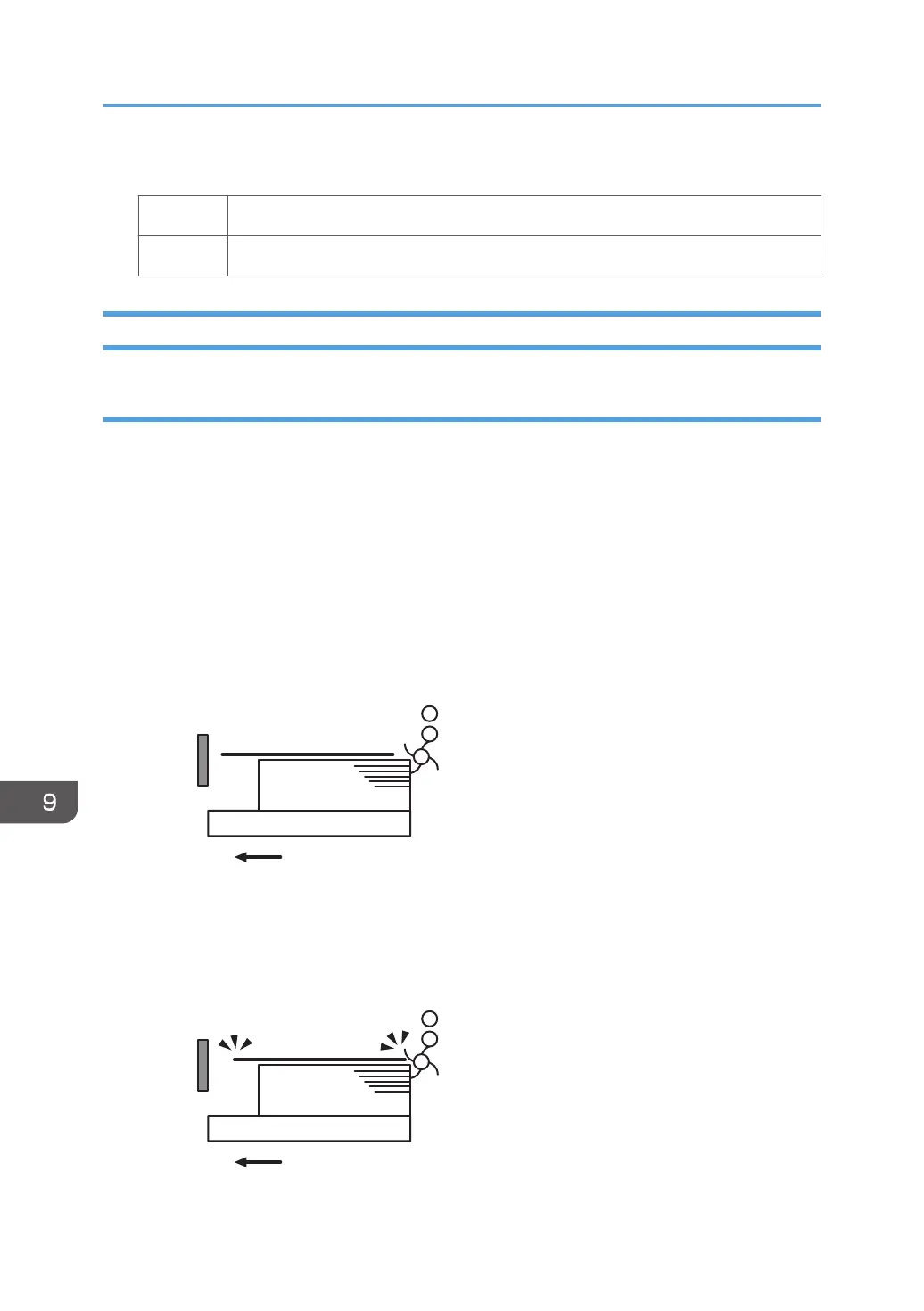

2. Strong friction occurs on the trailing edge so that the paddle cannot pull the sheet back and

align the edges of the sheet with those of the stack.

Paper feed direction

Stacker shift tray

Paper edge

stopper

Paper exit

Paddle

CEZ578

9. Post-Processing Option Troubleshooting

152

Loading...

Loading...