When installing the V ring, proceed in the same way as when installing the labyrinth ring.

1. Grease the axial sealing surface. The shaft seating remains ungreased.

2. Push the V ring ② onto the shaft.

The correct axial position of the V ring for the design with grease chamber has been reached

if the V ring sits approx. 0.2 mm behind the edge of the shaft heel. This position is the result

of installing the labyrinth sealing ring.

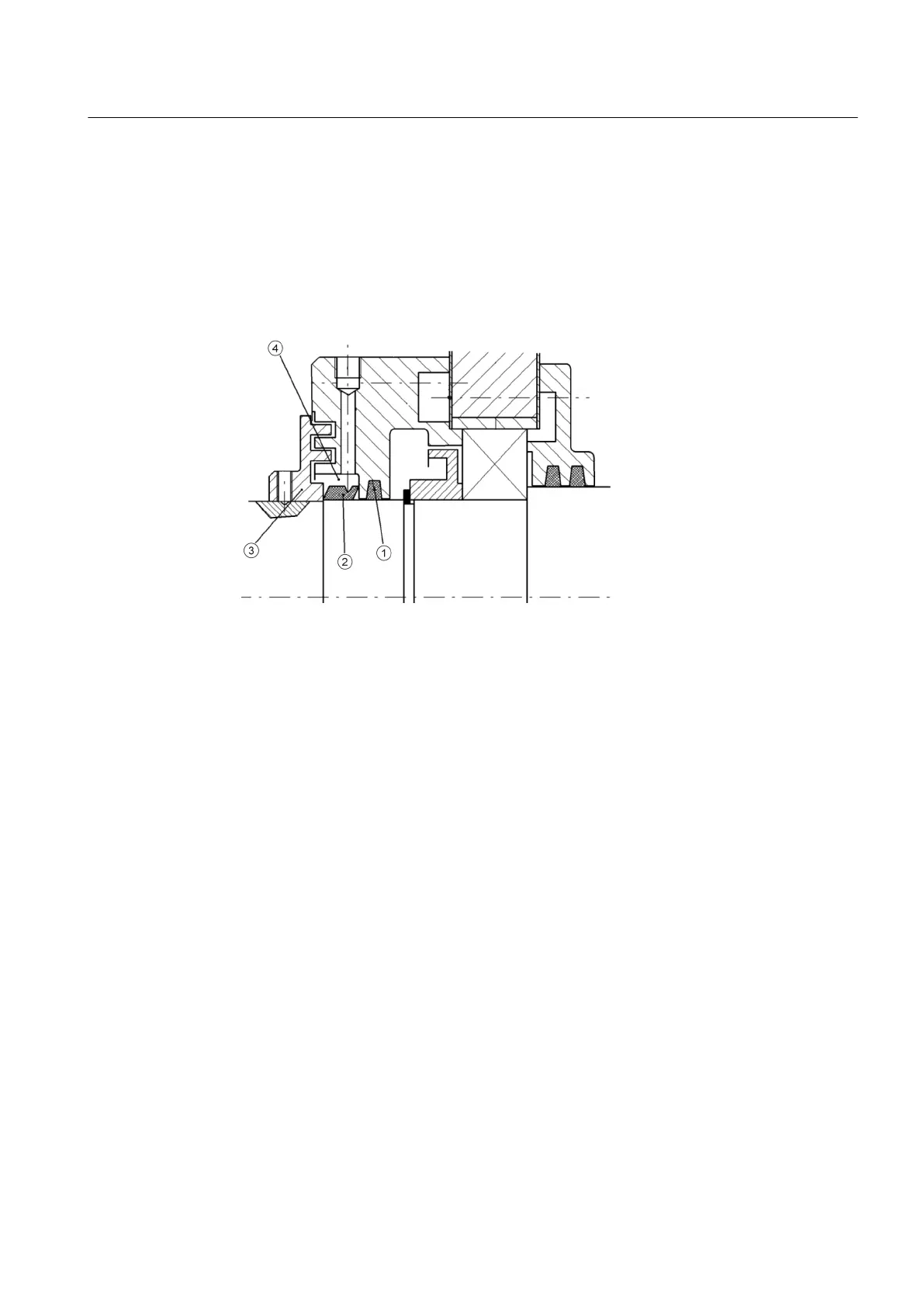

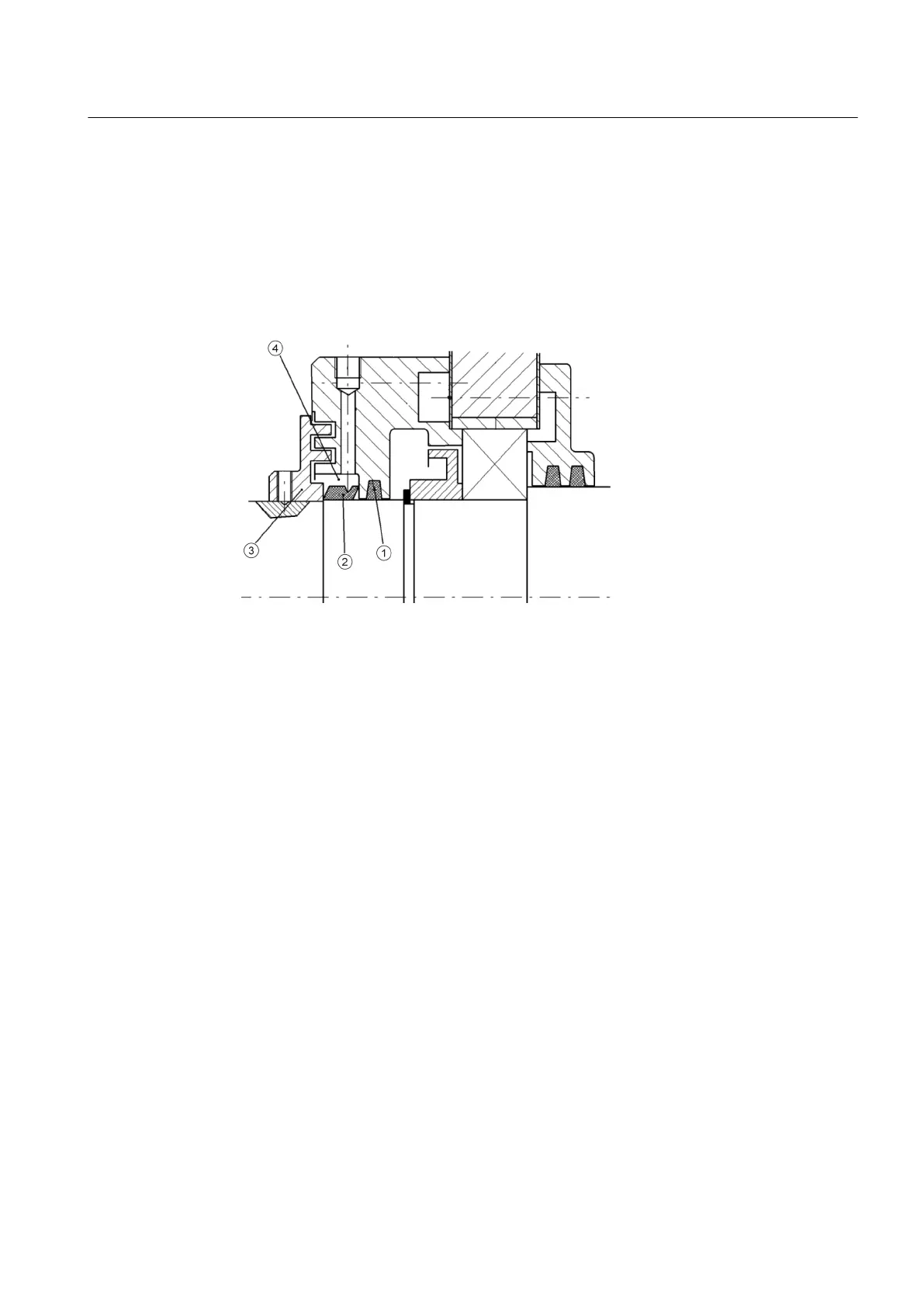

① Felt ring ③ Labyrinth sealing ring

② V ring ④ Grease chamber

Image 9-6 Roller-contact bearing with grease chamber (schematic diagram)

See also

Install the V ring (Page 113)

9.2.7.7 Installing the labyrinth sealing ring

The labyrinth sealing ring is the last component to be fitted when fitting the roller-contact

bearing. It ensures degree of protection IP65 and prevents the penetration of dirt and foreign

bodies into the roller-contact bearing.

1. Apply a soluble adhesive to the three set screws such as Loctite 243) and screw them

partially into the labyrinth sealing ring.

2. Apply an corrosion protection paint to the shaft in the area of the labyrinth sealing ring.

Maintenance

9.2 Corrective Maintenance

SIMOTICS TN Series N-compact 1LA8

Operating Instructions 05/2016 115

Loading...

Loading...