WARNING

The machine can fall over, shift or fall down during transport if the center of gravity is not

symmetrical

If the center of gravity of a load is not located centrally between the attachment points, the

motor can tip over or slip out of the lifting equipment and fall when it is being transported or

lifted. This can result in death, serious injury or material damage.

● Comply with the handling instructions on the machine when transporting it.

● Be aware of the possibility of different loads on the sling ropes or lifting straps and the

carrying capacity of the lifting equipment.

● Always take account of the center of gravity when transporting or lifting the motor. If the

center of gravity is not located centrally between the attachment points, then position the

hoisting hook above the center of gravity.

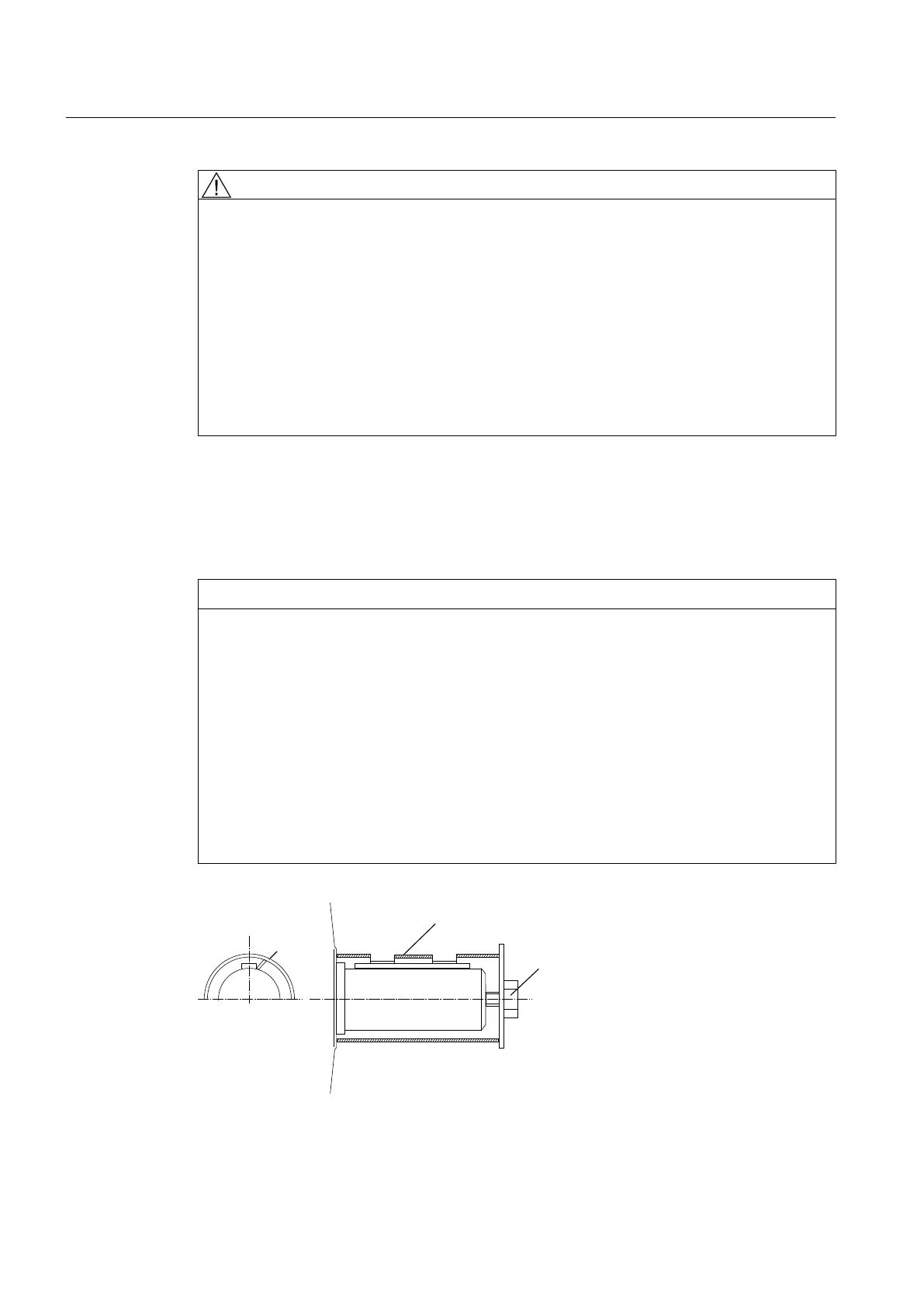

4.12.4 Securing the rotor

Depending on the version, the machine is fitted with a rotor shipping brace.

NOTICE

Damage during transport

Not using the rotor shipping brace can cause damage to the machine if it is jolted during

transport. Material damage can result.

● If the machine is fitted with a rotor shipping brace, this should always be used when

transporting the machine. It must be securely attached during transportation.

● Only remove it before pushing on the output element. If you transport the machine after

the output element has been pushed on you must take other appropriate measures to fix

the axial position of the rotor. Please refer to the illustration below.

● In the case of vertical design motors, disassemble the rotor shipping brace in the vertical

position only. Fix the rotor in position before the machine is turned onto its side if a machine

has to be transported in a horizontal position. Vertical motors are supplied from the

manufacturing plant in the horizontal position.

① Sleeve ② Screw and washer

Image 4-1 Axial location of the rotor

Preparations for use

4.12 Transport and storage

SIMOTICS TN Series N-compact 1LA8

32 Operating Instructions 05/2016

Loading...

Loading...