Getting Started

64 A5E37208904-003, 04/2017

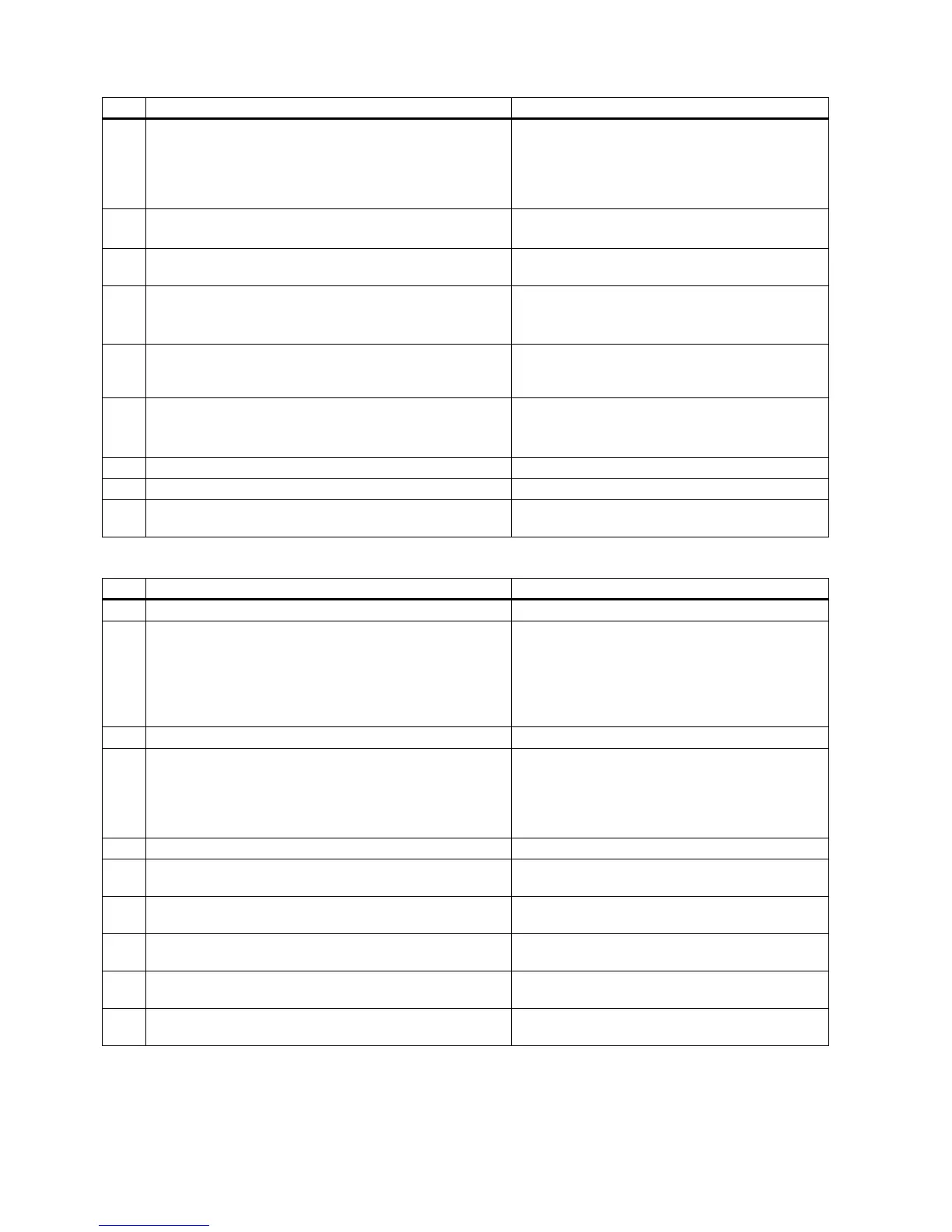

4 Check the servo motor type.

• If the servo motor has an incremental encoder, input the

motor ID (p29000).

• If the servo motor has an absolute encoder, the servo

drive can identify the servo motor automatically.

occurs when the servo motor is not

identified.

You can find the motor ID from the motor rating

plate. For the detailed information of the motor rating

plate, see Section "Motor components (Page 14)".

5 Switch to the basic positioner control mode by setting pa-

rameter p29003 = 1.

•

p29003 = 1: basic positioner control (EPOS)

p29003 = 2: speed control (S)

6 Save the parameter and restart the servo drive to apply the

setting of the basic positioner control mode.

7 Set the mechanical gear ratio with parameters p29247,

p29248 and p29249.

• p29247: LU per load revolution

• p29248: load revolutions

•

p29249: motor revolutions

8 Select the axis type by setting parameter p29245. If you use

the modular axis, you need to define the modular range by

setting parameter p29246.

• p29245 = 0: linear axis

• p29245 = 1: modular axis

9 Setting jogging setpoints with the appropriate parameters.

• Velocity (p2585, p2586)

•

Incremental (p2587, p2588)

Refer to "EJOG (Page 67)".

Switch on the main line supply.

Set up the PROFINET configuration with TIA Portal.

12 Select the telegram for PROFINET communication with

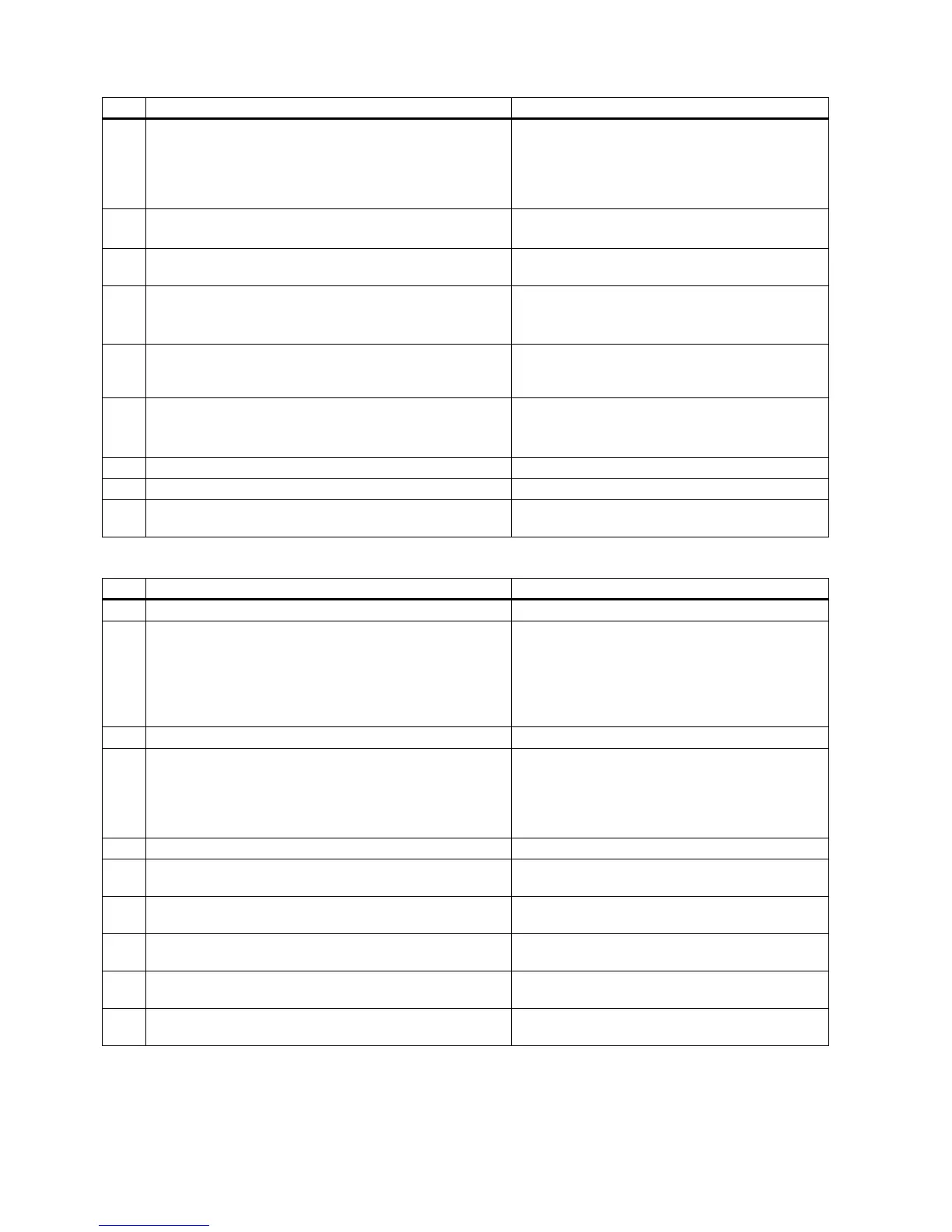

Commissioning in speed control mode (S)

Switch off the main line supply.

2 Power off the servo drive and connect it to the controller (for

example, SIMATIC S7-1500) with the PROFINET cable and

signal cable.

If any one of digital signals EMGS, CWL, and CCWL

is not assigned to a DI, it will be set to a high level

(1) automatically.

If you have assigned any one of digital signals

EMGS, CWL, and CCWL to a DI, keep it at a high

Switch on the 24 VDC power supply.

4 Check the servo motor type.

• If the servo motor has an incremental encoder, input

motor ID (p29000).

• If the servo motor has an absolute encoder, the servo

drive can identify the servo motor automatically.

occurs when the servo motor is not

identified.

You can find the motor ID from the motor rating

plate. Go to "Motor components (Page 14)" for de-

tailed descriptions about motor rating plate.

5 Set up the PROFINET configuration with TIA Portal.

6 Select the telegram for PROFINET communication with

7 Set the IP address for the station with parameters p8921,

8 Set the device name for the station with parameter p8920. The device name must be unique within the

9 Active the IP configuration and device name with parameter

10 Set the torque limitation and speed limitation. Refer to "Torque limit (Page 66)" and "Speed limit

Loading...

Loading...