7 - 18

7 Transmission Repair

7B Sauer-Sundstrand BDU-21L-207

Minor Repair

General

Minor Repairs may be performed, following the proce-

dures in this section, without voiding the unit warranty.

Cleanliness is a primary means of assuring satisfactory

transmission life, on either new or repaired units.

Cleaning parts by using a clean solvent wash and air

drying is usually adequate. As with any precision equip-

ment, all parts must be kept free of foreign materials and

chemicals.

Protect all exposed sealing surfaces and open cavities

from damage and foreign material.

It is recommended that all O-rings be replaced. Lightly

lubricate all O-rings with clean petroleum jelly prior to

assembly.

Plug / Fitting Torques

If any plugs were removed from the housing, center sec-

tion, or end cap during servicing, they should be torqued

as indicated in the accompanying tables:

ITEM TORQUE

Housing Plugs/Drains 29 to 50 ft. lbs.

(3/4-16 or 7/8-14 O-Ring) (39 to 68 Nm)

Bypass Passage Plug 56 to 50 ft.lbs.

(1/16-27 Pipe (6.4 to 16 Nm)

Loop Plugs 29 to 50 ft.lbs

(3/4-16 O-Ring) (39 to 68 Nm)

Inlet Fitting/Plug 15 to 35 ft.lbs.

(9/16-18 O-Ring) (20 to 47 Nm)

Plastic Inlet Fitting 25 to 30 in.lbs.

(M6 Screw) (2.8 to 3.4 Nm)

Figure B-4. Sauer-Sundstrand Hydrostatic Drive Unit

BDU-21-L-207

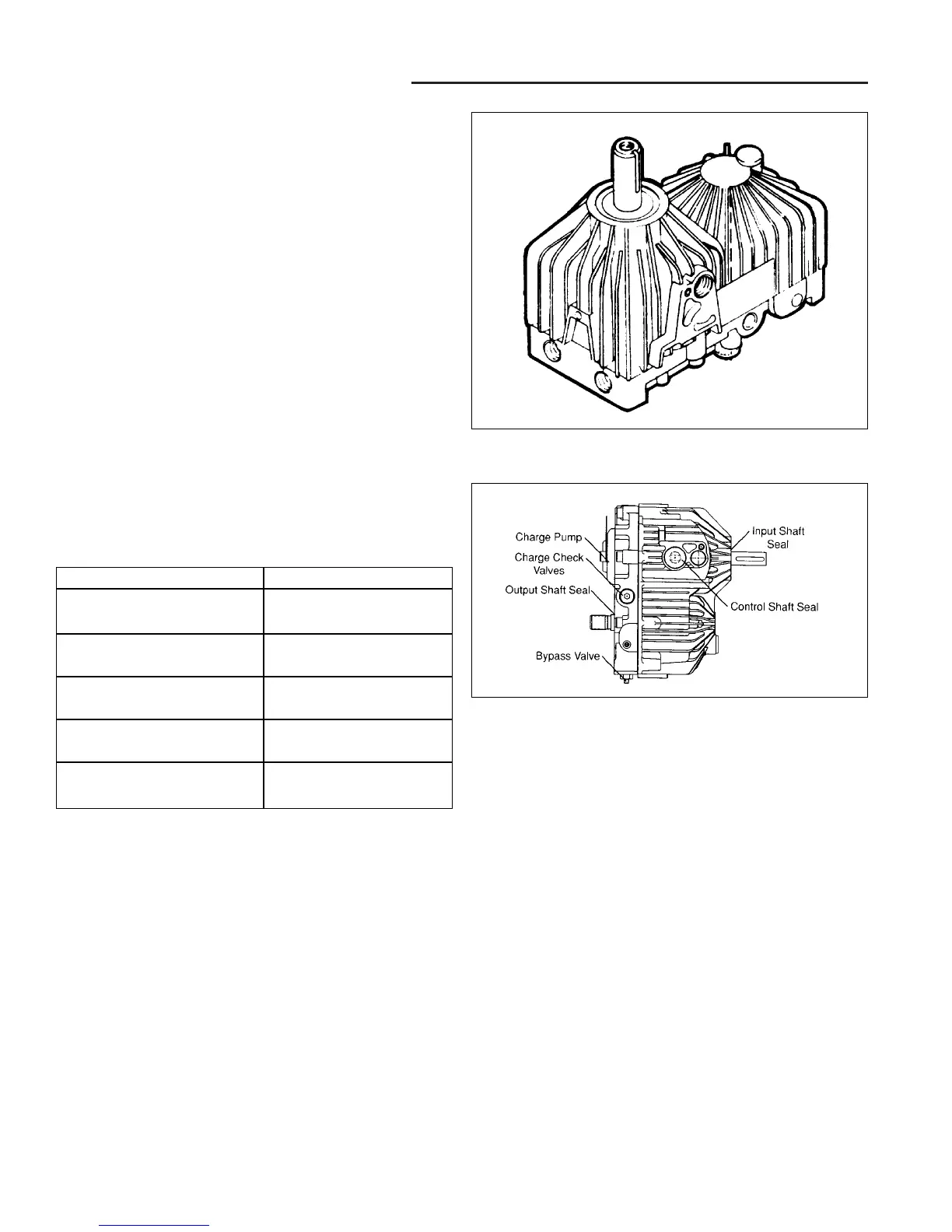

Figure B-5 Minor Repairs

Loading...

Loading...