MINOR REPAIR

Minor Repairs may be performed, following the proce-

dures in this section, without voiding the unit warranty.

Cleanliness is a primary means of assuring satisfactory

transmission life, on either new or repaired units.

Cleaning parts by using a clean solvent wash and air

drying is usually adequate. As with any precision equip-

ment, all parts must be kept free of foreign materials and

chemicals.

Protect all exposed sealing surfaces and open cavities

from damage and foreign material.

It is recommended that all O-rings be replaced. Lightly

lubricate all O-rings with clean petroleum jelly prior to

assembly.

Plug / Fitting Torques

If any plugs were removed from the housing, center sec-

tion, or end cap during servicing, they should be torqued

as indicated in the accompanying tables:

ITEM TORQUE

Housing Plugs/Drains 29 to 50 ft. lbs.

(3/4-16 or 7/8-14 O-Ring) (39 to 68 Nm)

Bypass Passage Plug 56 to 50 ft.lbs.

(1/16-27 Pipe) (6.4 to 16 Nm)

Loop Plugs 15 to 35 ft.lbs

(9/16-18 O-Ring) (20 to 47 Nm)

Inlet Fitting/Plug 8 to 20 ft.lbs.

(7/16-20 O-Ring) (11 to 27 Nm)

Figure D-3. Sauer-Sundstrand Hydrostatic Drive

Unit BDU-10-L

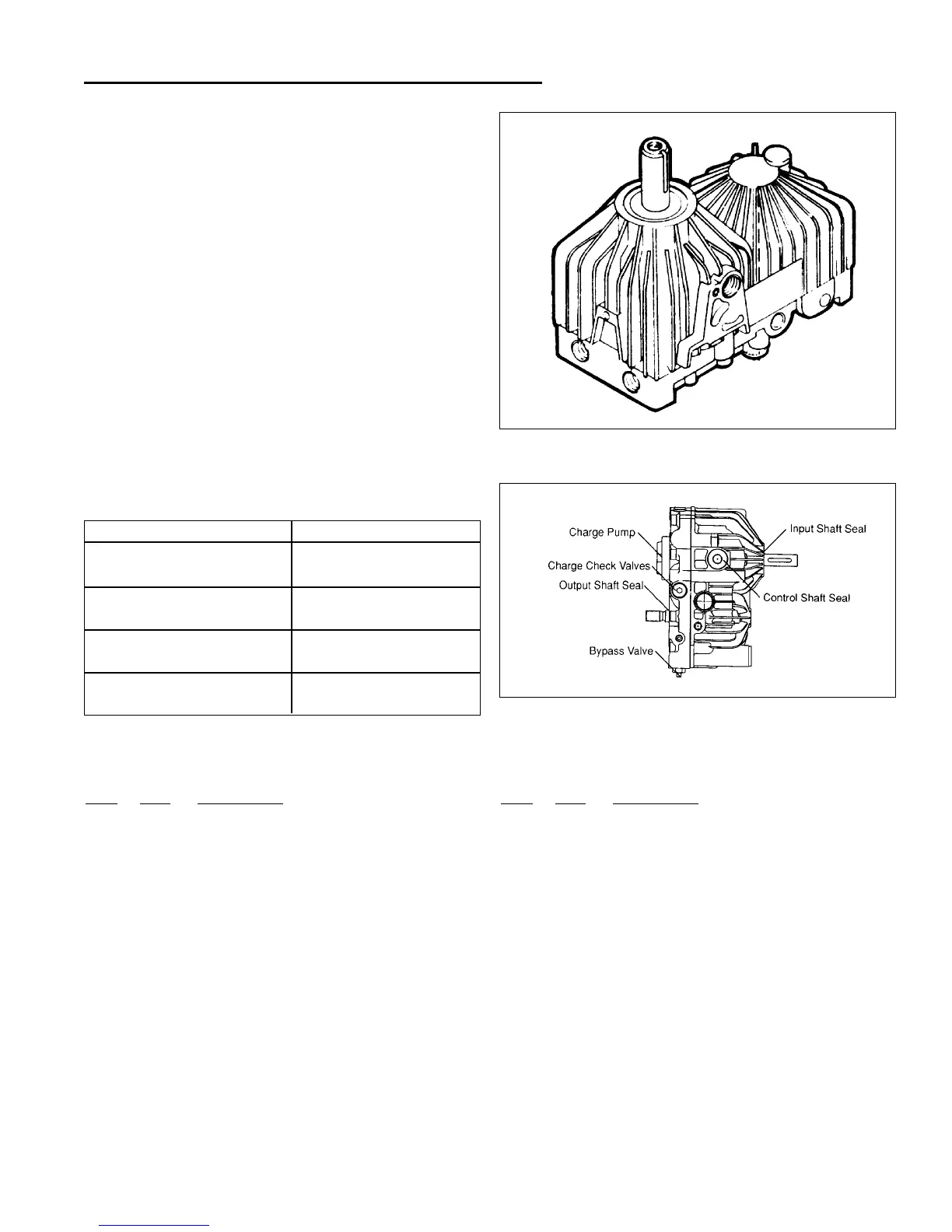

Figure D-4. Minor Repairs

7 - 49

7 Transmission Repair

7D Sauer-Sundstrand BDU-10L-258

Item Qty. Description

1.* 1 SPACER

2.* 1 SEAL

3.* 1 RETAINING RING

4.* 1 SEAL

5.* 1 SEAL

6.* 1 SEAL

7. 1 BYPASS VALVE KIT

8. 1 CAPSCREW, Socket Hd.

9.* 2 RETAINING RING

10. 1 BEARING. Shaft

11. 2 CRADLE, Bearing

12. 1 VARIABLE SWASHPLATE

13. 2 BLOCK ASSY.

14. 1 TRUNNION ARM

15. 1 GUIDE

16. 1 SPRING

17. 2 THRUST WASHER

Item Qty. Description

18. 2 PIN

19. 1 CHECK VALVE KIT, RH

20. 1 CHARGE RELIEF KIT

21. 1 CHECK VALVE KIT, LH

22 2 THRUST BEARING ASSY.

23.* 1 GASKET, Center Section

24. 1 PUMP SHAFT

25. 1 PUMP HOUSING KIT

26. 1 CENTER SECTION KIT

27. 1 MOTOR SHAFT

28.* 2 O-RING

29. 1 CHARGE PUMP KIT

30. 1 GEROTOR ASSY.

31. 2 CAPSCREW, 6M x 20

32. 2 SPACER PLATE

33. 3 DOWEL PIN

34. 1 CHARGE PUMP HOUSING

* Parts can be ordered as Overhaul Seal Kit.

Figure D-2. Hydro-Gear BDU10L-258 Hydrostatic Pump

Loading...

Loading...