7 - 67

7 Transmission Repair

7E Tuff Torq K210A

Inspection

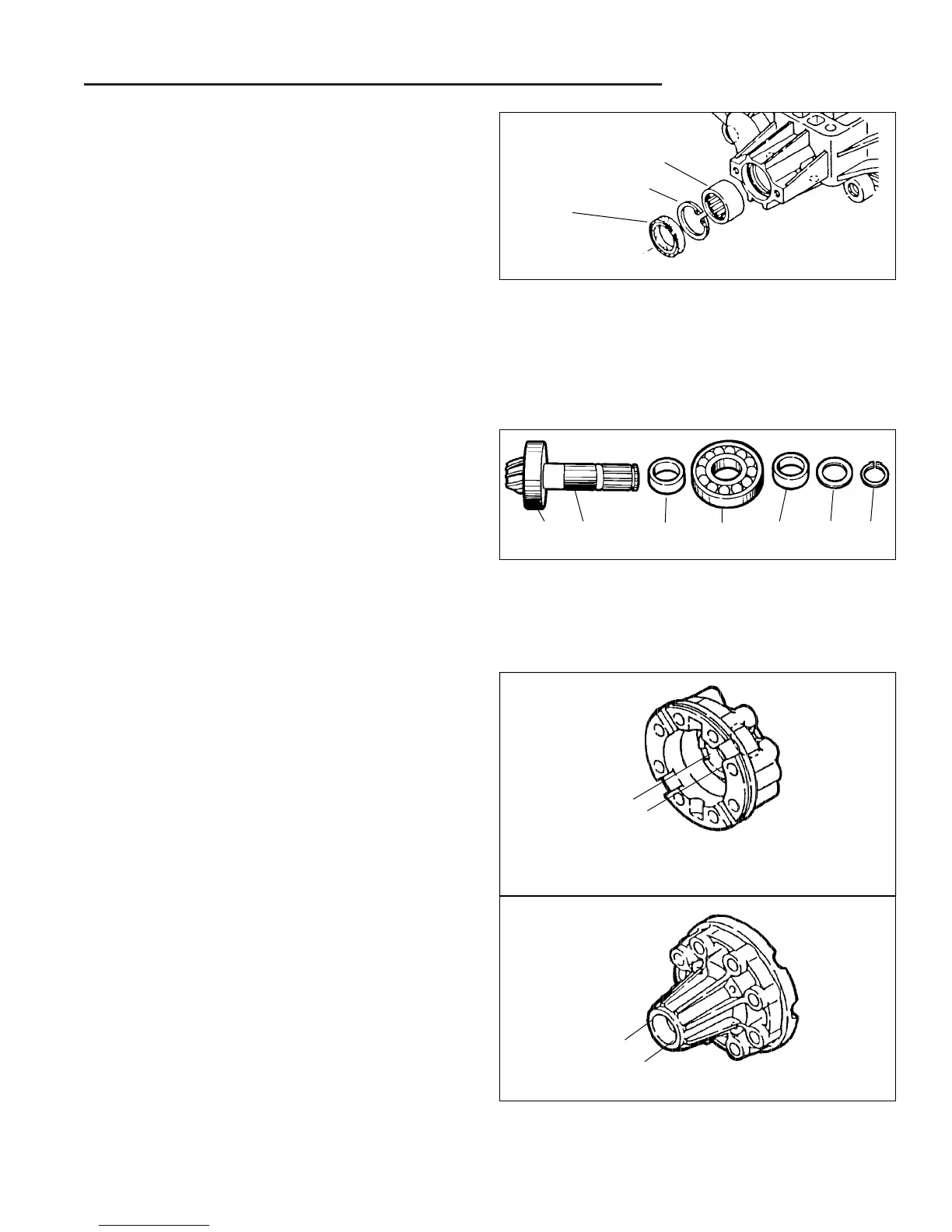

1. Inspect axle shaft needle bearings (inside left and

right side cases) for wear. If replacement is needed,

press old needle bearing out and install new as fol-

lows:

A. Press new bearing into case using driver which

only contacts outer shell of bearing. Drive in until

bearing is approximately 1/8" below edge of case.

B. Remove driver. Compress internal snap ring and

install into axle bore on top of needle bearing.

C. Reinstall driver on top of snap ring and drive

snap ring and bearing into case until snap ring is

seated in groove in case. Do not bottom needle

bearing in bore.

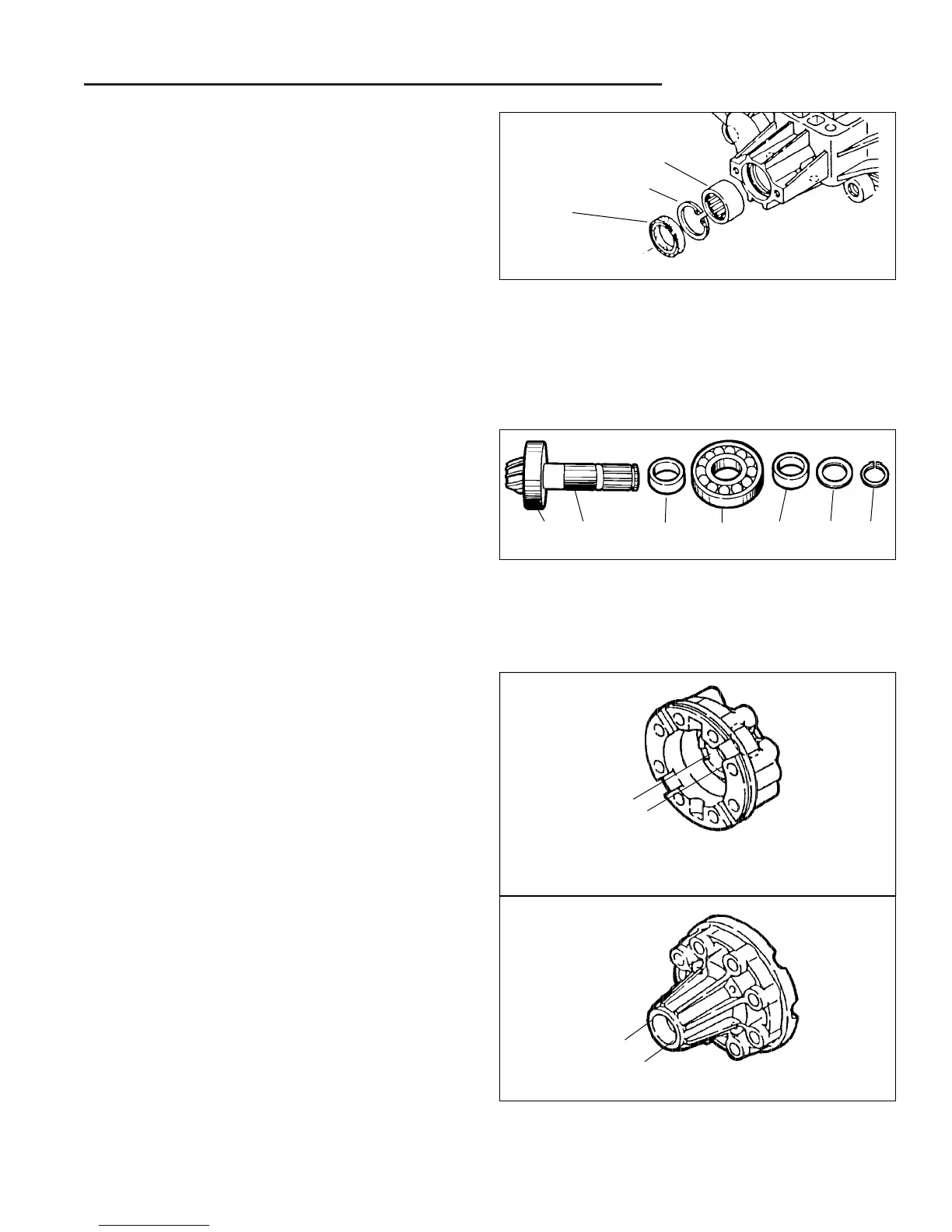

2. Inspect the input shaft components for wear or dam-

age.

Figure E-25. Input Shaft Components

A B C A D E F

A. Roller Bearing

B. Input Shaft

C. Collar

D. Sleeve

E. Washer

F. Internal Retaining Ring

Figure E-24. Remove Axle Shaft Needle Bearing

Needle Bearing

Internal Snap Ring

Axle Seal

3. Measure the differential housing:

A. Bushing Inside Diameter:

New: 27.97–28.15 mm

Maximum: 28.45 mm

B. Differential Case ID: 25.05–25.10 mm

4. Measure differential components and replace if not

within the following specifications:

Differential (Axle Shaft) Washer Thickness:

New: 0.73–0.87 mm

Minimum: 0.5 mm

Pinion Shaft Cupped Washer:

New: 0.75–0.85 mm

Minimum: 0.5 mm

Pinion Gear Inside Diameter: 14.016–14.034 mm

Pinion Shaft Outside Diameter: 13.966–13.984 mm

Pinion Shaft-to-Pinion Gear Clearance:

New: 0.032–0.068 mm

Minimum: 0.5 mm

B

A

Figure E-26. Inspect Differential Housing

Loading...

Loading...